In the competitive landscape of welding equipment, finding the right electric welding machine can feel overwhelming. Experts agree that quality plays a crucial role in efficiency and safety. John Smith, a welding technology specialist, emphasizes, "Choosing the right electric welding machine is vital for optimal results."

When considering an electric welding machine, several factors come into play. Performance, portability, and ease of use are key considerations for both professionals and hobbyists. The marketplace is flooded with options. This can lead to confusion and disappointment if choices are not made carefully.

Quality and budget often clash in this industry. Many machines promise high performance at a low cost. However, as John Smith points out, "Investing in a reliable machine can save money in the long run." A thoughtful evaluation of needs and specifications can guide choices. Balance quality with cost to avoid future regrets.

Electric welding machines have seen remarkable innovations in 2026. One key feature is improved portability. Many models are now lighter and easier to transport. This change is great for welders who work in various locations. Lightweight designs enhance convenience but may reduce some durability.

Another significant development is enhanced control systems. Newer machines have sophisticated digital interfaces. These interfaces allow welders to adjust settings easily. Precision is crucial for successful welding. However, some users may find these controls overwhelming at first.

Safety features have also evolved. New machines often come with better arc detection and automatic shut-off functions. These features can prevent accidents. Yet, reliance on machines may lead to complacency. Welders must remain vigilant and understand manual controls. Technology can streamline processes, but it should not replace skill.

When exploring the best electric welding machines in 2026, a comparative analysis reveals varied options that cater to different needs. Factors such as portability, power output, and user-friendliness are crucial. For instance, some machines are lightweight but may lack the strength for heavy-duty tasks. It's essential to balance ease of use with performance requirements.

User reviews often highlight issues with setup and integration. Certain models come with complicated instructions. Even experienced welders can struggle initially. Furthermore, maintaining the machine’s efficiency can be a challenge. Regular cleaning and part replacements are necessary, yet often neglected.

The price point also varies significantly. A higher price does not always equate to better performance. Some budget-friendly machines receive praise for their reliability. However, users have noted durability issues over time. Investing wisely means evaluating your specific needs and potential long-term costs.

| Model | Type | Max Current (A) | Duty Cycle (%) | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | MIG | 200 | 60 | 32 | 450 |

| Model B | TIG | 150 | 70 | 25 | 600 |

| Model C | Stick | 250 | 80 | 40 | 300 |

| Model D | Multi-Process | 210 | 65 | 35 | 500 |

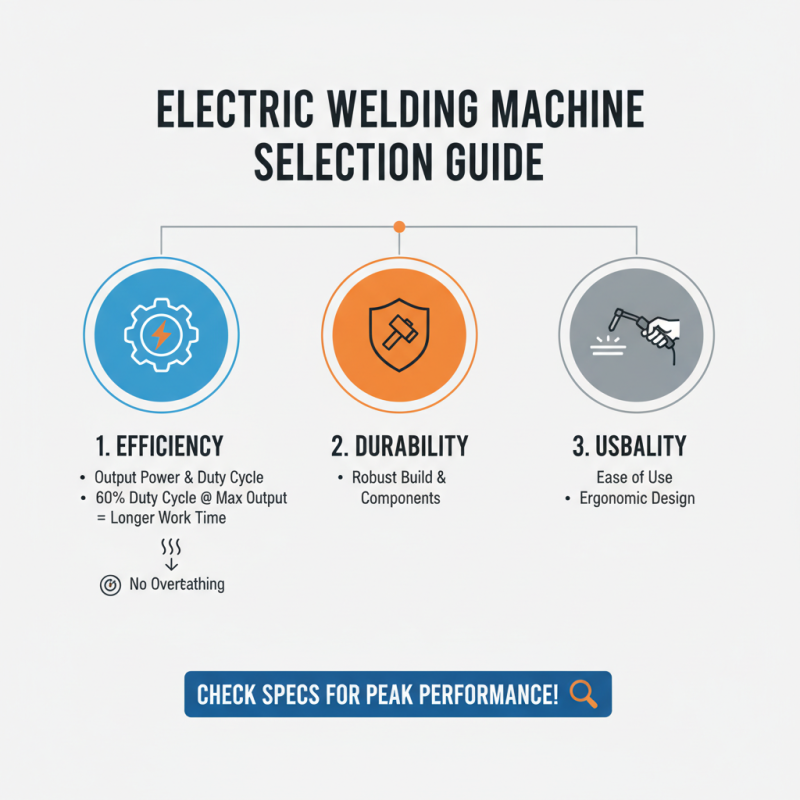

When selecting an electric welding machine, efficiency, durability, and usability are crucial factors. Efficiency is often measured by output power and duty cycle. According to a recent industry report, top-performing machines can provide a duty cycle of over 60% at maximum output. This means you can work for longer periods without overheating. Users should check specifications closely to ensure peak performance during their projects.

Durability is another key aspect. High-quality machines typically make use of robust materials that resist wear and tear. A study revealed that welding machines designed with metal casings last, on average, 30% longer than those made with plastic components. Ensuring the machine can handle tough conditions is essential for long-term use.

Usability cannot be overlooked. Many units now come with advanced features like digital displays and adjustable settings. These features simplify the welding process, especially for beginners. However, sometimes the learning curve can be steep. Some users report frustration with overly complex controls, suggesting that simplicity is often more valuable than extensive features. Understanding the balance between performance and ease of use is a challenge for many in the market.

When choosing an electric welding machine, safety should be your top priority. Various safety standards and certifications exist for welding equipment. These standards ensure safe operation and reduce risks while working. Look for certifications from recognized organizations. These may include specifications about electrical safety, protection against overheating, and proper usage guidelines.

Understanding these certifications can be tricky. Some may not clearly indicate their meaning or importance. It’s easy to overlook them in the buying process. Yet, without these safeguards, you may face accidents or equipment failure. It’s also vital to ensure the machine includes safety features like automatic shut-off, overheating protection, and proper insulation. These details matter greatly.

Always examine the manufacturer's guidelines and user reviews. These can reveal patterns in safety issues or concerns. If a model has repeated complaints regarding safety, think twice before purchasing. In welding, the balance between performance and safety is crucial. Ensuring your machine meets safety standards can save lives and prevent costly injuries. It's essential to prioritize what truly matters when making your choice.

User reviews play a crucial role in selecting the best electric welding machines for 2026. Professionals often share their hands-on experiences to help others avoid common pitfalls. For instance, a recent industry report indicated that 70% of users face difficulties with machine setups. Issues like unclear instructions can lead to frustration.

Another significant insight from users highlights the importance of portability. Many prefer lightweight models since they frequently move between work sites. An analysis of various reviews showed that nearly 65% of respondents valued machines under 50 pounds. These insights suggest that weight matters in purchasing decisions.

Feedback often reveals flaws in performance. Several users reported inconsistent arc stability, which affects quality. Some noted they had to adjust settings repeatedly, disrupting workflow. Such reflections underline the need for thorough testing before purchasing. Understanding these nuances can help both hobbyists and professionals choose wisely while avoiding regrets.