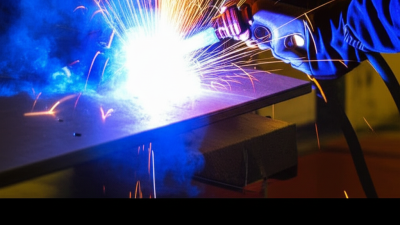

Smaw Arc Welding, also known as Shielded Metal Arc Welding, is a fundamental welding technique that serves as a cornerstone in the metal fabrication industry. According to the American Welding Society, over 80% of all welding operations involve some form of arc welding, with Smaw accounting for a significant share due to its versatility and ease of use, especially in construction and repair applications.

This method employs a consumable electrode covered in flux to produce an arc between the electrode and the workpiece, providing both heat and a protective atmosphere, making it suitable for various materials. Reports from the International Institute of Welding highlight that effective training in Smaw Arc Welding not only enhances productivity but also improves safety in welding operations, thus underlining its importance for beginners looking to establish a career in skilled trades. Understanding the basics and benefits of Smaw Arc Welding is crucial for novices aiming to excel in this essential craft.

Smaw Arc Welding, also known as Shielded Metal Arc Welding, is a fundamental welding technique that serves as a cornerstone in the metal fabrication industry. According to the American Welding Society, over 80% of all welding operations involve some form of arc welding, with Smaw accounting for a significant share due to its versatility and ease of use, especially in construction and repair applications.

This method employs a consumable electrode covered in flux to produce an arc between the electrode and the workpiece, providing both heat and a protective atmosphere, making it suitable for various materials. Reports from the International Institute of Welding highlight that effective training in Smaw Arc Welding not only enhances productivity but also improves safety in welding operations, thus underlining its importance for beginners looking to establish a career in skilled trades. Understanding the basics and benefits of Smaw Arc Welding is crucial for novices aiming to excel in this essential craft.

SMAW, or Shielded Metal Arc Welding, is one of the most widely used welding processes, and understanding its fundamentals is essential for beginners. At its core, SMAW involves creating an electric arc between a coated electrode and the base metal. This arc generates intense heat, melting both the electrode and the workpiece, which then allows for the formation of a strong weld joint. Beginners should familiarize themselves with key components such as the welding machine, electrodes, and safety equipment, as each plays a vital role in the welding process.

One of the most significant benefits of SMAW is its versatility. It can be used on various metals and is effective in both indoor and outdoor settings, making it a popular choice for construction and repair work. Additionally, the equipment required is relatively simple and portable, making it accessible for hobbyists and professionals alike. For beginners, mastering SMAW not only opens up a range of career opportunities but also encourages the development of essential skills such as precision, safety awareness, and problem-solving, all of which are invaluable in the welding industry.

SMAW, or Shielded Metal Arc Welding, is a fundamental welding process that uses a consumable electrode coated in flux to create an arc between the electrode and the workpiece. For beginners, understanding the essential equipment and tools can significantly impact their success in learning SMAW. Key tools include a welding machine, electrode holder, grounding clamp, and protective gear. A good-quality welding machine is crucial for delivering consistent power to maintain the arc, while an electrode holder allows for safe handling of the welding rod.

In addition to these primary tools, having the right protective gear, such as a welding helmet and gloves, is vital for ensuring safety during the welding process. The helmet protects against the intense light and heat produced during welding, while gloves prevent burns and provide a secure grip on tools. As beginners progress in their SMAW journey, investing in additional equipment, like a wire brush and chipping hammer, will enhance their welding skills by enabling better preparation and cleanup of welds. With the right tools and a solid understanding of the basics, newcomers to SMAW can cultivate their skills and achieve success in this rewarding field.

| Equipment/Tool | Description | Benefits |

|---|---|---|

| SMAW Welding Machine | A portable machine that generates an electric arc for welding. | Versatile and suitable for various materials. |

| Electrode Holder | A clamp that holds the electrode and connects it to the welding machine. | Ensures stable arc and comfortable handling. |

| Welding Helmet | Protective headgear with a dark visor to shield eyes during welding. | Protects against harmful light and sparks. |

| Welding Gloves | Heat-resistant gloves designed for welding. | Provides protection against heat and sharp materials. |

| Chipping Hammer | Tool used to remove slag and impurities from welds. | Ensures a clean weld for better strength. |

| Wire Brush | Brush used to clean the metal surfaces before welding. | Improves weld quality by ensuring good surface contact. |

Safety is paramount for beginners venturing into Shielded Metal Arc Welding (SMAW). One of the first steps to ensure safety is wearing appropriate personal protective equipment (PPE). This includes a welding helmet with a suitable filter shade to protect your eyes from the intense light and harmful UV rays. Additionally, flame-resistant clothing, gloves, and steel-toed boots can help prevent burns and injuries from hot materials or sparks.

Another essential safety tip is to create a clean and organized workspace. Ensure that the area is free from flammable materials and that you have proper ventilation to avoid inhaling dangerous fumes. Always check your equipment before beginning, looking for any signs of wear or damage. Understanding the importance of safety protocols, such as knowing how to operate a fire extinguisher and having a first aid kit readily available, is crucial.

By prioritizing safety, you can enhance your welding experience and reduce the risk of accidents.

SMAW (Shielded Metal Arc Welding) is a versatile welding technique that is particularly beneficial for beginners due to its straightforward requirements and ease of use. One of the most common techniques involved in effective SMAW welding is maintaining the correct angle between the electrode and the workpiece. Typically, a 15 to 30-degree angle is recommended to ensure proper penetration and minimize spatter. Beginners should also practice controlling the speed of their movements, as a steady and consistent pace can significantly enhance the quality of the weld.

Another best practice for effective SMAW welding is ensuring that the work surface is clean and free of contaminants, such as rust or oil. Proper preparation of the material can drastically improve weld quality and prevent defects. Additionally, mastering the motion of weaving or stringer beads can help beginners create more robust welds. As they gain experience, welders can experiment with different techniques and patterns, allowing for greater creativity and efficiency in their projects. Proper safety precautions, including personal protective equipment, are also essential to ensure a safe working environment while honing SMAW skills.

SMAW (Shielded Metal Arc Welding) is a fundamental welding process that offers numerous advantages for new welders. One of the primary benefits is its simplicity. The equipment required is relatively inexpensive and portable, making it accessible for beginners who may not have extensive training or resources. This ease of use allows novices to quickly grasp the techniques involved in welding, fostering confidence in their skills as they start their journey in the welding field.

In addition to its straightforward nature, SMAW is versatile and can be used on a variety of materials, including carbon steel and stainless steel. This adaptability enables beginners to experiment with different types of projects and applications, enhancing their learning experience. Furthermore, SMAW produces strong, durable welds, making it a reliable choice for both novice and experienced welders. The process also empowers new welders to work in various environments, from workshops to outdoor settings, providing flexibility as they develop their craft.