In recent years, the demand for Digital Welding Machines has surged. The global market is projected to reach $9.73 billion by 2025. This growth is fueled by increasing automation and advancements in technology. A Digital Welding Machine provides precision and efficiency, essential for modern fabrication processes.

Choosing the right unit can be overwhelming. With numerous options available, understanding your specific needs is vital. Some users may focus on portability, while others prioritize power and features. According to reports, 47% of professionals seek machines with advanced functionalities. Yet, many still grapple with their decision-making processes.

Reflecting on personal experiences and industry reviews can shed light on the ideal machine for each task. Users often find themselves torn between budget-friendly options and high-end devices. Finding a balance is challenging. By evaluating key aspects such as duty cycle, weight, and usability, you can make an informed decision.

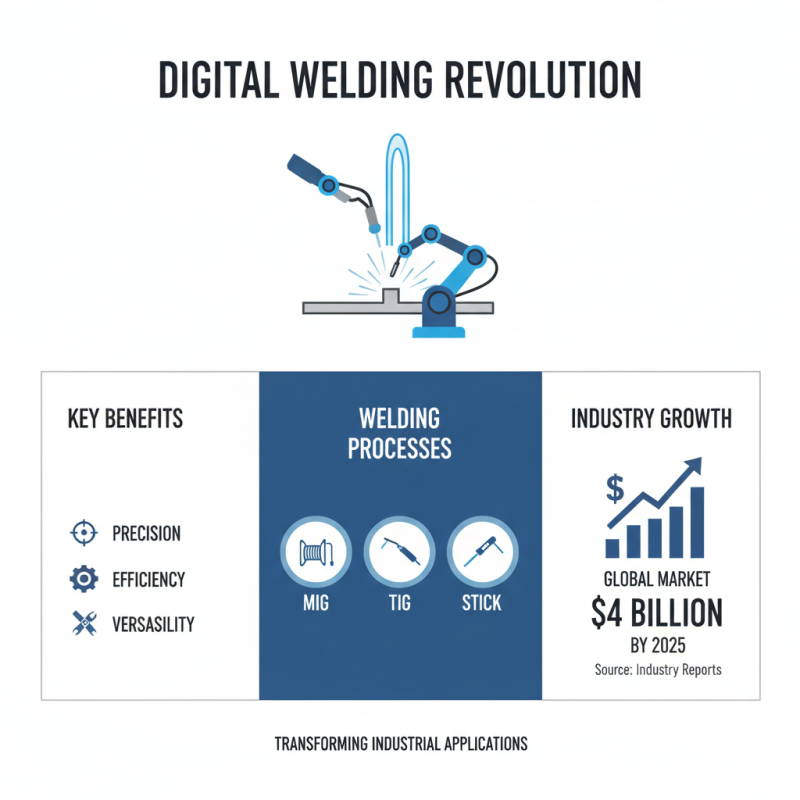

Digital welding machines have transformed the welding industry. They offer precision, efficiency, and versatility. These machines are designed for various welding processes, such as MIG, TIG, and Stick welding. According to industry reports, the digital welding market is expected to reach $4 billion by 2025. This growth highlights their importance in industrial applications.

When considering a digital welding machine, buyers should think about their specific needs. Are you working on heavy industrial tasks or small home repairs? The technology can vary significantly based on usage. Many machines come with advanced features like digital control panels. They may also offer automatic settings for various materials. Yet, not all machines excel in every situation. It's vital to assess the types of projects you’ll undertake.

Tips: Always check the machine’s duty cycle. A higher duty cycle means less downtime during welding tasks. Look for units that are user-friendly, even for beginners. Remember, a complicated interface can lead to errors. Finally, while some machines boast impressive features, simplicity often proves effective in practical applications. Evaluation and reflection on your specific requirements are crucial.

Digital welding machines have revolutionized the industry. Various types serve distinct applications. Understanding these types is vital for selecting the right machine.

MIG (Metal Inert Gas) welders are popular for their ease of use. They are perfect for thin materials and quick tasks. A report by the Welding Association notes that 65% of hobbyists prefer MIG welders due to their versatility. TIG (Tungsten Inert Gas) welders offer precision. They excel in projects requiring fine detail, like automotive or aerospace applications. However, they can be challenging for beginners.

Stick welders are another option. They are excellent for outdoor projects and tough conditions. The portability makes them a go-to for construction sites. According to industry data, 25% of welding professionals favor stick welding due to its durability.

Tips: When choosing a machine, consider the material and thickness you'll work with. Digital features can enhance control but may require additional training. Read user reviews for real-life insight into performance. Remember, the best machine is the one that fits your unique needs.

| Type | Application | Power Source | Portability | Typical Price Range |

|---|---|---|---|---|

| MIG Welding Machine | Suitable for thin materials, automotive repairs. | Electric | Moderate | $200 - $1,500 |

| TIG Welding Machine | Ideal for stainless steel and aluminum. | Electric | Moderate to High | $300 - $3,000 |

| Stick Welding Machine | Useful for outdoor welding, thicker materials. | Electric or Gasoline | High | $150 - $800 |

| Multi-Process Welder | Versatile for various materials and processes. | Electric | Moderate | $500 - $2,000 |

| Plasma Cutter | Cutting metal with precision. | Electric | Moderate to High | $300 - $1,800 |

When choosing a digital welding machine, several key features demand attention. Consider the type of welding processes you require. MIG, TIG, or stick welding each has unique strengths. Some machines excel in versatility, while others may specialize. Knowing your project needs will greatly influence your choice.

Power capability is another crucial factor. Look for machines with adjustable settings. This allows for flexibility based on metal thickness. A machine that struggles with power settings might lead to inconsistent welds. It's essential to match the machine's output with your materials. When in doubt, consult user manuals or guides.

Portability and weight can impact usability. A heavier machine may limit your work area. On the other hand, highly portable models might sacrifice power. Find a balance that suits your workspace. Additionally, ensure the machine offers user-friendly controls. Complex interfaces can be frustrating, especially for beginners. These considerations will lead to more satisfying welding experiences.

In the ever-evolving landscape of welding technology, digital welding machines are gaining traction. Recent industry reports indicate that the market for these machines is expected to grow at a compound annual growth rate (CAGR) of over 7% through 2026. This growth reflects increasing demand in various sectors, particularly automotive and construction. Digital machines offer precise control, enhancing the quality of welds significantly.

When evaluating top brands and models, it's crucial to consider features like power output and adaptability. Many users highlight the importance of user-friendly interfaces and real-time feedback during operation. However, some models may lack the versatility required for diverse welding tasks. Additionally, while advanced features enhance performance, they can also complicate maintenance and repair processes. Users often report frustration when navigating these complexities.

The choice of a digital welding machine should align with specific needs. For instance, lightweight machines are fantastic for portability but may compromise power. On the other hand, heavier models often provide robust performance but at the cost of maneuverability. Finding that balance can be challenging. Ultimately, the ideal machine will depend on individual user requirements and the intended application.

Maintaining and operating a digital welding machine requires attention to detail. Regular cleaning is crucial. Dust and debris can easily affect performance. Simply wiping down surfaces and ensuring ventilation can enhance longevity. Some reports suggest that a 10% reduction in contaminants can extend the lifespan of welding equipment significantly.

Correct setup and operation are equally important. Many users overlook the significance of adjusting settings. Each material requires specific voltage and amperage. According to industry studies, improper settings can lead to a 30% increase in wear and tear. Familiarize yourself with these settings by consulting user manuals. This can reduce mistakes and improve efficiency.

Regular inspections cannot be ignored. Check cables, connections, and safety features often. A slight fray in cables can create hazards. Additionally, many operators fail to monitor gas levels consistently. Inadequate gas can lead to poor weld quality. Keeping a close watch on these details can prevent costly errors down the line. Be proactive in your maintenance routine to ensure optimal performance.