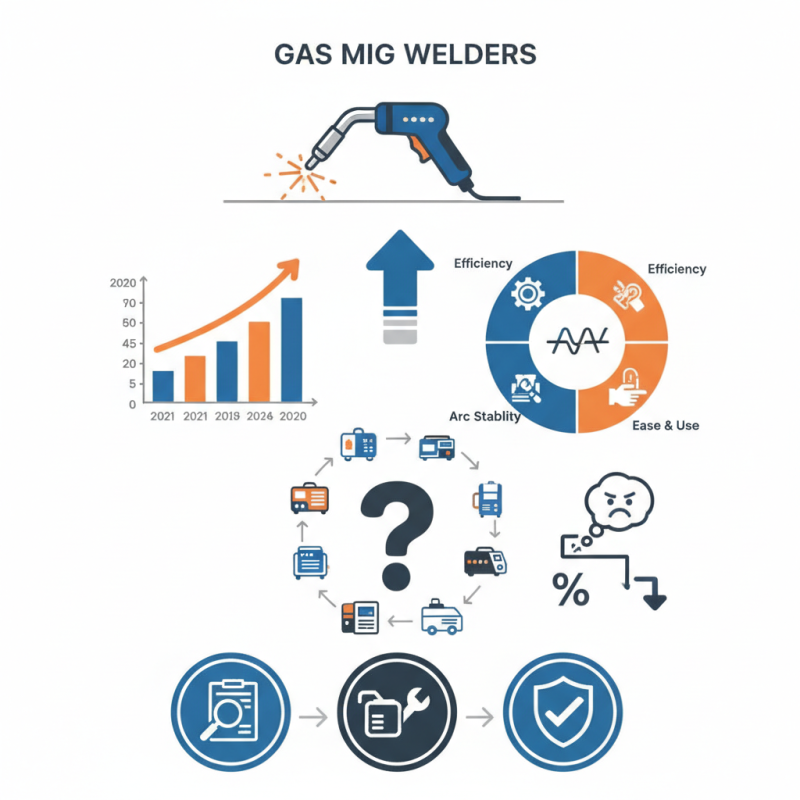

In the realm of welding, the Gas Mig Welder is a significant tool. According to industry reports, the global welding market reached USD 21.6 billion in 2021 and is projected to grow at a CAGR of 4.2% from 2022 to 2030. This indicates a continual embrace of advanced welding technologies, including gas MIG welding.

Technological advancements have improved efficiency and versatility. Users now benefit from better arc stability and improved ease of use. However, with the growth of this segment, the sheer number of options can be overwhelming. Recent studies show that 40% of welders regret their choice of equipment after purchase.

Quality and performance are crucial, yet many overlook essential factors. Understanding specifications, maintenance, and usability is vital. Gas MIG welding can be an asset, but the wrong choice could lead to frustrations. Each welder has unique needs, and not all products fit every user. Careful consideration is key to finding the right gas MIG welder.

A gas MIG welder is a versatile tool used mainly in metal fabrication. It employs a shielding gas to protect the weld pool from contaminants. This process helps achieve a cleaner and stronger bond between metals. The welder feeds a continuous wire electrode from a spool. The welder makes it easy for both beginners and experienced users.

In practice, gas MIG welding requires a bit of practice to master. Adjusting the gas flow, wire speed, and voltage can be tricky. The right balance is crucial for quality welds. A user might face challenges like burn-through or weak welds if settings are off. Understanding the equipment's mechanics is essential.

Having good welding techniques is necessary but not always guaranteed. A stable hand and adequate speed are important for a smooth weld. However, it often takes several attempts to produce perfect seams. Beginners may find it frustrating at times. Practice really does make perfect, but it also requires patience and reflection.

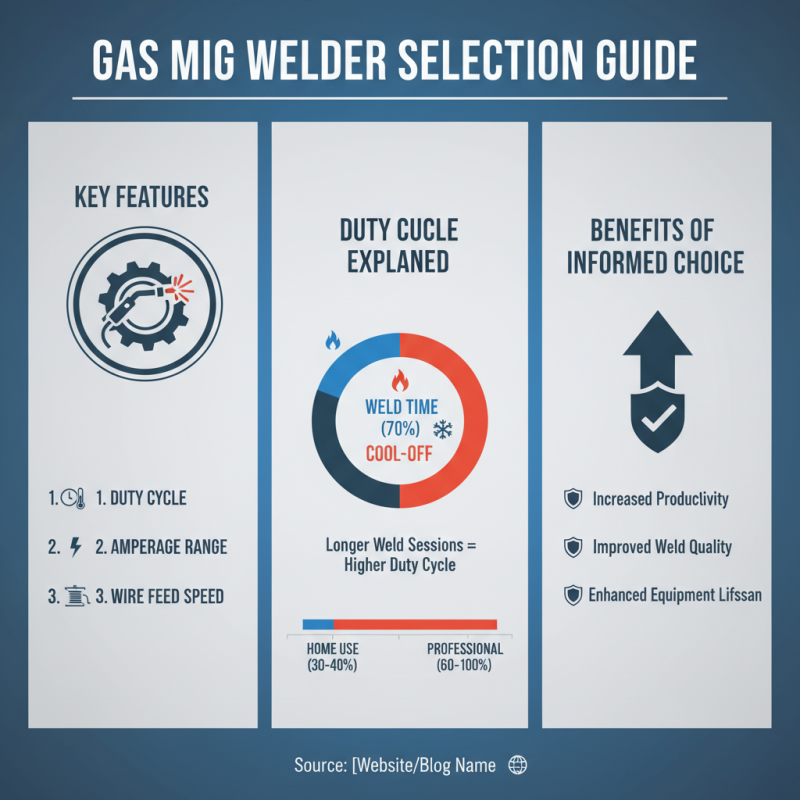

When selecting a gas MIG welder, key features play a critical role. Understanding these factors ensures that you make an informed purchase. One essential aspect is the welder's duty cycle. This metric indicates how long the machine can operate before needing a cool-off period. A higher duty cycle allows for longer welding sessions, which is invaluable in professional settings.

Another crucial feature is the welding range. Different projects require various thicknesses of material. A machine that offers multiple voltage settings provides flexibility for diverse tasks. According to industry data, MIG welders with adjustable settings are preferred by 78% of professionals. This adaptability leads to better results across projects.

Additionally, gas type matters. Mixing argon and CO2 improves penetration and bead appearance. However, the performance may vary. Some users find that certain gas mixtures produce spatter, resulting in additional cleanup time. Considering the right gas can improve overall efficiency but demands experimentation and adjustment to find the best mixture for your specific applications. Selecting a gas MIG welder involves weighing features against personal needs.

When it comes to MIG welding, gas MIG welders are an excellent choice for beginners in 2026. These machines are versatile and easy to use, making them suitable for a variety of projects. According to industry reports, the market for MIG welders is expected to grow by 4.5% annually. This indicates a rising interest among DIY enthusiasts and professionals alike.

For novices, gas MIG welders provide cleaner welds compared to others. The shielding gas creates a protective layer, preventing contamination. This feature is crucial for beginners who may struggle with technique. Many newcomers often overlook the importance of gas selection, impacting weld quality. A poor choice can lead to excessive spatter and weak joints, which require additional cleanup efforts.

While shopping for a gas MIG welder, beginners should consider key features. Adjustable voltage settings and wire feed speed are essential for precise control. However, many units may lack intuitive user interfaces. A complex machine can overwhelm newcomers, leading to frustration. This scenario is common and can deter users from progressing in their welding skills. It's vital to find a balance between features and user-friendliness.

In 2026, the demand for advanced gas MIG welders is on the rise, particularly for professional use. These machines offer increased versatility and precision, making them essential in many industries. Reports indicate that over 40% of professionals prefer gas MIG welding for its clean finish and deeper penetration. This preference is largely due to the benefits of shielding gas, which minimizes defects in the welds.

One key area to consider is the power output. Many advanced models can achieve higher amperage, which translates to better performance on thicker materials. This is significant since about 60% of welding jobs involve heavy-duty tasks. However, training becomes crucial. Many users may find themselves struggling with settings and techniques at first. This learning curve can be frustrating, but professional workshops can help. Environments vary, and layouts can create challenges. Solutions might include setting up designated workspaces to enhance efficiency.

Welders should also be aware of the safety aspects. Gas MIG welding, while effective, poses hazards if not handled correctly. It requires constant attention and the proper protective gear. Surprisingly, recent studies show that improper safety practices lead to 30% of welding accidents. Thus, ongoing training and adherence to safety protocols are paramount for every professional welder.

| Model | Welding Process | Max Output (Amps) | Voltage | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | Gas MIG | 250 | 220V | 50 | 800 |

| Model B | Gas MIG | 300 | 240V | 65 | 1,200 |

| Model C | Gas MIG | 200 | 230V | 55 | 700 |

| Model D | Gas MIG | 350 | 230V | 70 | 1,500 |

Maintaining a gas MIG welder is crucial for its performance and lifespan. Regular upkeep can prevent breakdowns and ensure consistent weld quality. According to industry reports, proper maintenance can extend equipment life by up to 30%. Checking gas levels frequently is essential. Low gas can lead to poor shielding, resulting in weld defects. Refilling before usage minimizes interruptions during projects.

Cleaning the contact tip is another vital step. A clogged tip can affect wire feeding and result in erratic arcs. It’s recommended to clean it after every 5-10 hours of use. Replace worn tips and nozzles promptly. This small action significantly enhances weld smoothness. Moreover, check and tighten all electrical connections regularly. Loose wiring can lead to inconsistent power delivery.

Lastly, don’t overlook the importance of storing the welder properly. Keep it away from moisture and extreme temperatures. While it's easy to neglect these simple steps, ignoring them could lead to costly repairs. A little attention to detail goes a long way in keeping your gas MIG welder operating efficiently.