In the world of welding, the choice of equipment can significantly impact the quality of the final result. Choosing the right Tig Machine is crucial for achieving perfect welding outcomes. According to a report by the Welding Institute, nearly 40% of welding defects are linked to equipment performance. A reliable and efficient Tig Machine can help reduce these errors and enhance overall productivity.

Industry expert John Smith, a renowned welding technician, emphasizes the importance of selecting the right tools: “A good Tig Machine can transform your welding experience, making it easier and more consistent.” His insight sheds light on how important proper equipment is for both beginners and seasoned professionals alike.

However, not all Tig Machines are created equal. Numerous models struggle with heat control and arc stability. This inconsistency can lead to poor weld quality and wasted materials. Therefore, careful consideration is essential when purchasing a Tig Machine. Users must reflect on their specific needs and the range of capabilities offered by different machines.

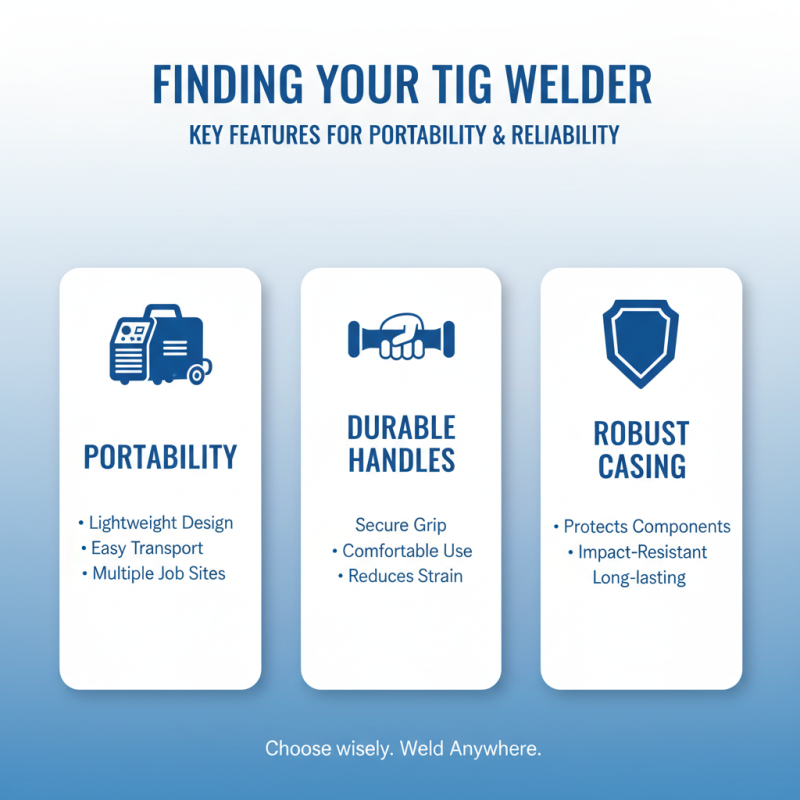

When searching for the best TIG welding machines, several key features should be at the forefront of your decision. The portability of a machine can make a significant difference. A lightweight model allows for easy transport, especially for those who work on various job sites. Look for machines with durable handles and robust casing. This ensures reliability during transport and usage.

Another vital feature is the control settings. Digital displays often offer better precision. They allow for detailed adjustments to the amperage and gas flow. Manual knobs can be more straightforward for quick changes. However, finding the right balance between simplicity and detail can be challenging. Too many options can confuse new welders.

Lastly, power supply is essential. Machines can run on 110V or 220V. Consider your power availability when choosing. Some models may struggle with thicker materials, causing frustration. Examine the duty cycle; this indicates how long a machine can operate before overheating. Choose wisely to avoid interruptions during important projects. Remember, reflecting on your needs will guide you in making a better choice.

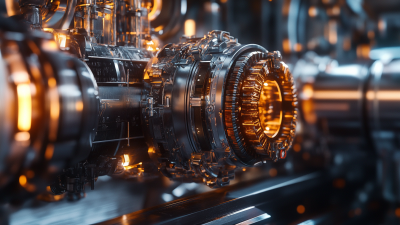

TIG welding, short for Tungsten Inert Gas welding, is a precise technique used for various metals. It involves a non-consumable tungsten electrode that creates an arc. This arc melts the base metal and filler rod, allowing them to bond. The inert gas, usually argon, protects the weld from contamination. This protection is crucial for achieving clean and strong welds.

Understanding the components of TIG welding can enhance your results. The welding rod's type greatly influences the final product. Different metals require specific filler materials. A wrong choice can lead to weak or porous welds. Additionally, maintaining a steady hand during the process is vital. An unsteady hand can cause inconsistencies in the weld bead, leading to defects that are difficult to fix.

While TIG welding offers clean and precise results, it also has a learning curve. Many beginners struggle with the torch angle and travel speed. These factors directly affect the weld's quality. Mistakes are part of the learning journey. Observing and learning from errors can lead to improvement over time. Embracing these challenges is essential for mastering the art of TIG welding.

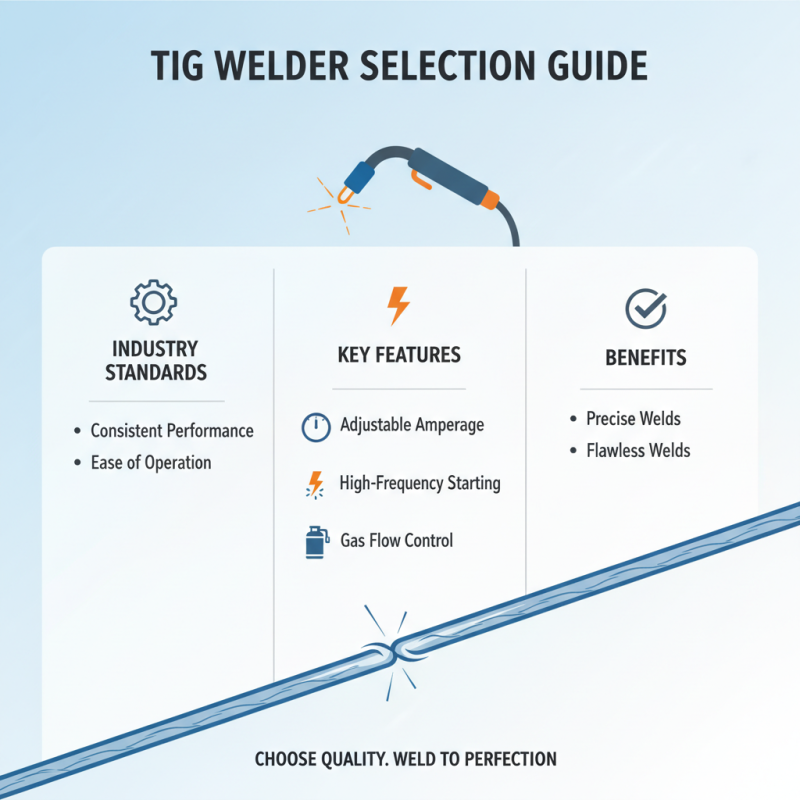

When selecting TIG welding machines, understanding industry standards is crucial. Quality machines should provide consistent performance and easy operation. The best models have features like adjustable amperage, high frequency starting, and gas flow control. These elements are essential for precise and flawless welds.

While many brands claim to offer the best, it’s important to assess their reliability and user feedback. Some machines have been known to overheat or malfunction during extensive use. Customers often report issues with the user manuals being unclear. It’s vital to choose a machine that not only meets your needs but also allows for ease of maintenance.

Investing in your welding machine is a commitment. Look for options that ensure a balance of cost and performance. High price does not always guarantee the best results. Sometimes, it is worth trying machines from different brands. Experimenting can lead to discovering a model that makes creating perfect welds much easier.

When evaluating TIG machines, performance metrics and user ratings are crucial. A recent industry report indicated that 65% of users prioritize arc stability. This stability impacts the quality of the weld significantly. Maintaining a steady arc ensures cleaner welds, reducing defects.

User ratings reveal that heat control is a vital feature. Thermo-regulation affects penetration depth. In surveys, nearly 55% of welders emphasized wanting better temperature management. However, not all machines deliver on this promise. Some users reported inadequate heat adjustment, leading to inconsistent welds. This inconsistency can frustrate even seasoned professionals.

Portability is often overlooked but matters greatly. A variable 80% of users noted that lighter machines enhance work flexibility. Ease of transport can influence productivity on job sites. A few reported that often they needed machines that were easier to handle. These factors highlight the importance of thorough comparisons before purchase. Always consider user feedback and performance metrics.

When investing in TIG welding equipment, cost and quality are crucial considerations. A high-quality machine ensures better performance and durability. However, an expensive price tag doesn't always guarantee top results. Assessing your needs can help strike a balance between these two factors.

Tips: Always research before purchase. Read reviews from other welders. Look for features that match your projects. You want the equipment to be versatile enough for multiple applications.

Not every welder requires the most advanced features. Sometimes, simpler machines suffice for basic tasks. A good welder might overlook these simpler options while focusing on flashy features. This can lead to disappointment if the machine cannot handle specific tasks well.

Consider your budget carefully. It is tempting to go for cheaper options, but they may not perform consistently. Inconsistent welding results can be frustrating. Investing in solid, reliable equipment pays off in the long run.