Choosing the right Flux Core Welder can significantly influence your welding experience. According to a report from the American Welding Society, the demand for skilled welders is expected to grow by 6% over the next decade. This makes selecting a suitable welder crucial for beginners eager to enter the industry.

When starting, novices often overlook important features of Flux Core Welders. Factors like wire feed speed, power output, and usability can affect overall performance. Many beginners invest in the cheapest option, thinking it will suffice. However, this often leads to frustration and subpar results. A well-chosen welder can simplify the learning curve.

To navigate this decision, focus on essential specifications. Look for a welder that balances quality and affordability. Analyze user reviews and industry ratings. A few minutes of research can save hours of headaches. As you embark on your welding journey, remember that the right Flux Core Welder sets the foundation for success.

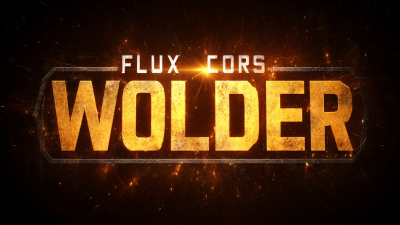

Flux core welding is a popular choice among beginners. This method uses a continuous wire feed. The wire serves as both an electrode and a filler material. It is often used in construction and repair work. Its flexibility makes it ideal for various tasks.

Understanding how flux core welding works is crucial. The welding process generates heat, melting the wire and base material. The flux within the wire produces a shielding gas. This gas protects the weld from contaminants. However, controlling this process can be tricky for newcomers. Proper technique is important to avoid defects. Beginners may find it challenging to maintain a steady hand.

Applications of flux core welding are wide-ranging. It's effective for outdoor projects because it is less sensitive to wind. Farmers and auto mechanics often use it. While it has many advantages, the learning curve can be steep. Many new welders struggle with consistency. Mistakes are common and can lead to poor-quality welds. Embracing these challenges is part of the learning experience.

When starting your welding journey, understanding your specific needs is crucial. There are different welding techniques, and flux core welding tends to be more forgiving for beginners. It’s vital to recognize what projects you plan to tackle. Data shows that around 70% of amateur welders begin with metal fabrication tasks. Knowing this helps you choose a welder suited for such applications.

Consider the materials you will work with. For example, steel and aluminum are common choices. Flux core welders excel in thicker materials, typically ranging from 18-gauge to 1/2-inch steel. This makes them ideal for outdoor projects, where wind can affect shielding gas. Furthermore, it’s essential to assess your workspace. If you work indoors, you might face challenges such as smoke and fumes. This is where a good helmet and ventilation come into play.

Take time to reflect on your welding environment. Are you comfortable with just the basics, or do you see yourself progressing? Some beginners find the learning curve steeper than expected. According to industry reports, about 30% of novice welders abandon the hobby within a year. Reassessing your motivations and goals can help ensure you choose the right welder for your needs. Finding the right balance of power and portability is key for long-term satisfaction.

| Feature | Importance for Beginners | Notes |

|---|---|---|

| Amperage Range | High | Flexible range allows for thin to thick materials. |

| Wire Size Compatibility | Medium | Common sizes generally suit most beginner projects. |

| Weight | Medium | Lightweight models are easier to maneuver. |

| User-Friendly Controls | High | Simplified settings aid beginners in learning. |

| Duty Cycle | Medium | Higher duty cycles allow for longer use without overheating. |

| Price | High | Beginner-friendly options within budget help with entry costs. |

When selecting a flux core welder, several key features can play a crucial role in your decision. Power output is essential; look for models that offer varying voltage settings. Higher wattage provides better penetration and works well with thicker materials. A good welding machine should also be lightweight and portable. This is helpful for beginners who might want to practice in different locations.

Another critical feature is the welding speed adjustment. Many beginners overlook this but it can greatly influence the quality of the weld. Too fast can lead to weak joints. Too slow may cause burn-through. Additionally, consider the gas capabilities. Some welders can function with and without gas. This flexibility is important for various projects. Also, examine the ease of use. Beginner-friendly controls are vital for learning quickly and effectively.

Finally, do not forget about safety features. Built-in protection against overheating or voltage spikes is crucial. It prevents damage and ensures a longer lifespan for your equipment. Each choice impacts your welding experience. Reflecting on these features can help you become a more skilled welder. It’s more than just picking the right machine; it’s about enhancing your craft.

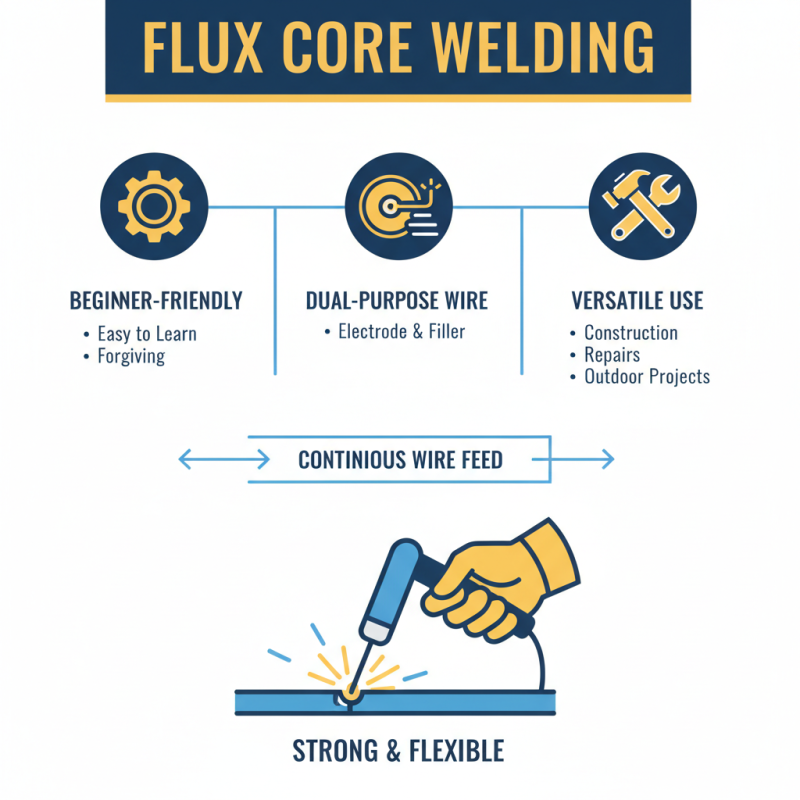

Budgeting for your first flux core welder can be crucial. Determine how much you can realistically spend. Set aside funds not only for the welder but also for additional essentials. These may include gas, wires, and safety gear. It’s easy to underestimate costs. You might find unexpected fees or tools that you really need.

Research different options within your budget. Some welders offer great features at lower prices. Consider local suppliers for deals. Don’t rush into a purchase. Look for used equipment as a viable option. This could save you money without sacrificing too much quality.

Make a checklist of everything needed. This will prevent overspending on unnecessary accessories. For example, safety glasses are essential. You may also want a welding helmet that fits well. Remember, safety should never be compromised. Allocate a small portion of your budget for personal protective equipment. It's an investment in your well-being as you learn to weld.

When starting with flux core welding, safety gear is crucial. A proper welding helmet can protect the eyes from harmful UV rays and sparks. According to industry reports, around 33% of welders face eye injuries due to inadequate protection. Wearing gloves is just as important. Specialized welding gloves made from leather or flame-resistant materials are recommended. They provide a better grip and protect your hands from heat.

Additionally, don’t overlook the importance of clothing. Fire-resistant clothing made from cotton or similar fabrics helps minimize burn risks. Many professionals suggest using a welding jacket for added protection. In fact, studies indicate that 40% of welding injuries relate to heat exposure. Even a simple pair of boots can make a difference; steel-toe boots protect against heavy items that may fall during a project.

Finally, ventilation cannot be ignored. Flux core welding can produce harmful fumes. Ensure your workspace is well-ventilated. A fan or exhaust system will help reduce the concentration of fumes. Many beginners underestimate the risk of inhalation. Inadequate ventilation can lead to long-term health issues, which make it an essential part of your safety precautions. Always be mindful of your environment and gear; it truly shapes your welding experience.