In recent years, the popularity of Inverter Welders has surged due to their efficiency and versatility in various welding applications. According to a report by the Welding Equipment Manufacturers Division, the global inverter welder market is projected to grow at a compound annual growth rate (CAGR) of 6.5% from 2021 to 2027. This growth is driven by advancements in inverter technology, making these welders increasingly efficient and allowing for greater control over welding processes.

Industry expert Dr. Emily Thompson, a senior researcher at the International Welding Institute, emphasizes the importance of selecting the right Inverter Welder for specific projects. She noted, "Choosing the right inverter welder is crucial for achieving optimal results—different projects require different capabilities." With the myriad of options available, understanding the key features and specifications of inverter welders becomes essential for both novice and seasoned welders.

As you embark on the journey to find the best Inverter Welder for your welding projects, consider the factors that will best meet your needs, including power output, duty cycle, and portability. Making an informed decision can significantly enhance your welding experience and lead to superior project outcomes.

Inverter welders have revolutionized the welding industry by combining advanced technology with efficiency and ease of use. Their compact design and lighter weight make them a popular choice for both amateur and professional welders. Unlike traditional transformer-based welding machines, inverter welders use sophisticated electronics to convert power, allowing for better control over the welding process. This results in smoother arcs, reduced energy consumption, and the ability to operate on varying voltage levels, making them versatile for different tasks and environments.

One of the primary benefits of inverter welders is their ability to deliver consistent performance even in challenging conditions. They are designed to provide precise voltage control, which is crucial for achieving high-quality welds. Additionally, many inverter welders come equipped with features such as Hot Start and Anti-Stick, which enhance the welding experience by minimizing common issues that beginners often face. The portability and user-friendly nature of these machines make them ideal for construction sites, repair shops, and home projects, where mobility and reliability are paramount. Overall, understanding the advantages of inverter welders can significantly impact your welding projects, offering both efficiency and exceptional results.

When selecting the best inverter welder for your welding projects, it is essential to focus on several key specifications that can significantly impact performance and ease of use. One crucial factor is the machine's duty cycle, which indicates the amount of time the welder can operate without overheating. According to industry reports, a duty cycle of 60% at a specific amperage is a good standard for most welding tasks, especially for amateur to intermediate welders. This percentage means that the welder can operate for 6 minutes continuously before requiring a 4-minute cooldown.

Another important specification to consider is the type of welding the inverter welder can perform. Most models offer versatility in welding processes such as MIG, TIG, and stick welding. A study by the American Welding Society emphasizes that integrating multiple welding capabilities can enhance the utility of the welder for diverse projects, providing greater flexibility for users. Additionally, evaluating the output range in amperage is vital, as it determines the thickness of the materials you can effectively weld. Typically, a range of 20 to 250 amps accommodates a wide variety of applications, ensuring you can work on everything from thin sheet metal to thicker steel components.

Lastly, consider the welding inverter's weight and form factor. Portability is often a critical factor for many users, particularly for those working on-site or in tight spaces. Reports indicate that lightweight models weighing under 50 pounds are increasingly popular, offering significant mobility without sacrificing performance. Assessing these specifications will ensure you select an inverter welder that meets your specific welding needs and project requirements.

| Specification | Description | Importance |

|---|---|---|

| Power Output | Measured in Amperes, determines the maximum thickness of the material you can weld. | Crucial for selecting a welder that meets your project needs. |

| Duty Cycle | Percentage of time the welder can operate in a given period (typically in 10 minutes). | Important for understanding how long you can weld continuously. |

| Weight | Refers to the portability of the welder. | Essential for users needing to move their equipment frequently. |

| Voltage | Input voltage options, commonly 110V or 220V, affects where you can use the welder. | Decisive for compatibility with power outlets available at your location. |

| Welding Process | Types of welding supported (MIG, TIG, Stick). | Determines versatility and suitability for various projects. |

| Control Settings | Adjustability of settings like voltage and wire feed speed. | Influences the precision and quality of your welds. |

| Safety Features | Includes features like overheat protection and safety shut-off. | Essential for ensuring user safety during operation. |

When selecting the right inverter welder for your welding projects, it's essential to consider the popular models and brands currently available on the market. According to a recent industry report, the global inverter welder market is projected to grow at a compound annual growth rate (CAGR) of 5.8% from 2023 to 2030. This growth is driven by advancements in technology and the increasing demand for portable, efficient welding solutions across various sectors.

Several models stand out due to their robust performance and user-friendly features. For instance, many leading inverter welders are now equipped with advanced inverter technology, allowing for a smoother and more stable arc, which ultimately enhances welding quality. Reports indicate that inverter welders are preferred over traditional transformer welders due to their lighter weight and energy efficiency, with some models offering as much as a 30% reduction in power consumption. This aspect alone can be a deciding factor for many professionals and hobbyists alike who aim to improve their workspace efficiency and reduce operational costs.

Additionally, the user interface of these models has evolved, with many now featuring digital displays and programmable settings. Such innovations not only simplify the welding process but also cater to a wide range of welding techniques, from MIG and TIG to stick welding. Industry studies show that these features are prominent in high-demand products, highlighting the significance of versatility in contemporary welding equipment choices. Therefore, understanding the key features and performance metrics of various inverter welder models can be pivotal in making an informed decision.

When selecting the right inverter welder for your projects, it's essential to start by understanding the specific requirements of your tasks. Consider the materials you will be welding, as different metals require different welding processes and settings.

For instance, if you’re primarily working with thin materials, you might benefit from a welder that offers excellent control over the heat output to prevent burn-through. Conversely, for thicker materials, a more powerful unit may be necessary. Evaluating the thickness of the materials and the types of welds required will guide you toward the appropriate welder specs.

Another crucial factor to consider is portability and convenience. Many inverter welders are designed to be lightweight and compact, making them easier to transport between job sites. Think about where you will be using the welder and whether you need one that can operate on different power supplies or is generator-capable. Additionally, check for features such as digital displays for easier setting adjustments, as these can enhance user experience, especially for beginners. Ultimately, evaluating these aspects will help you make an informed decision that aligns with your specific welding needs.

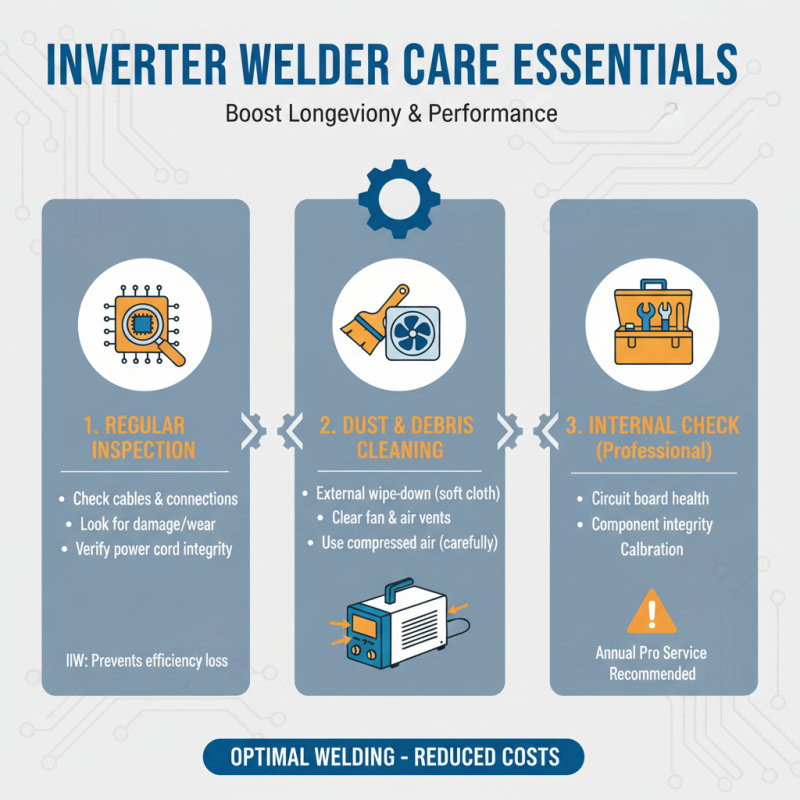

Proper maintenance and care for your inverter welder are essential to ensure its longevity and optimal performance. Regular inspection and cleaning are crucial; according to the International Institute of Welding, neglecting routine maintenance can lead to a reduction in welding efficiency and an increase in operational costs. Inverter welders, due to their compact design, often accumulate dust and debris that can affect the cooling systems. It is recommended to clean the unit externally with a soft cloth and to regularly check the fan and air vents for any blockages.

Additionally, keeping an eye on consumables such as electrodes, cables, and connectors is vital. The American Welding Society suggests that worn or damaged parts can not only compromise the quality of your welds but also pose safety risks. Always replace any parts showing signs of wear before they fail completely. Furthermore, periodic calibration of the settings is advised to maintain precision. A study from Welding Research Council indicates that routine calibration can improve weld quality by up to 20%. By implementing these maintenance practices, you can ensure that your inverter welder operates at its best, delivering efficient and high-quality results for your projects.