As the welding industry evolves, the demand for high-quality welder equipment continues to increase, with a projected market value expected to reach $16 billion by 2025, according to recent industry reports. The advancements in technology have transformed the capabilities of welding machines, enabling both professionals and hobbyists to achieve more precise and efficient results. In this landscape, selecting the right welder equipment is crucial, as it directly influences the quality of the completed projects and overall productivity.

John Smith, a well-respected expert in the welding equipment domain, emphasizes the importance of making informed decisions: “Choosing the right welder equipment is not just about brand preference; it’s about aligning the equipment capabilities with the specific needs of your projects.” This insight highlights the pivotal role that understanding the various features and specifications plays in enhancing performance, safety, and long-term durability. The continual advancements in welder equipment, coupled with a robust range of applications in industries such as construction, automotive, and manufacturing, make it imperative for users to stay informed about the best options available.

Therefore, as we delve into the intricacies of selecting the best welder equipment for your projects, we will explore vital considerations such as power source, portability, and compatibility to ensure that your choice will lead to successful and satisfying results.

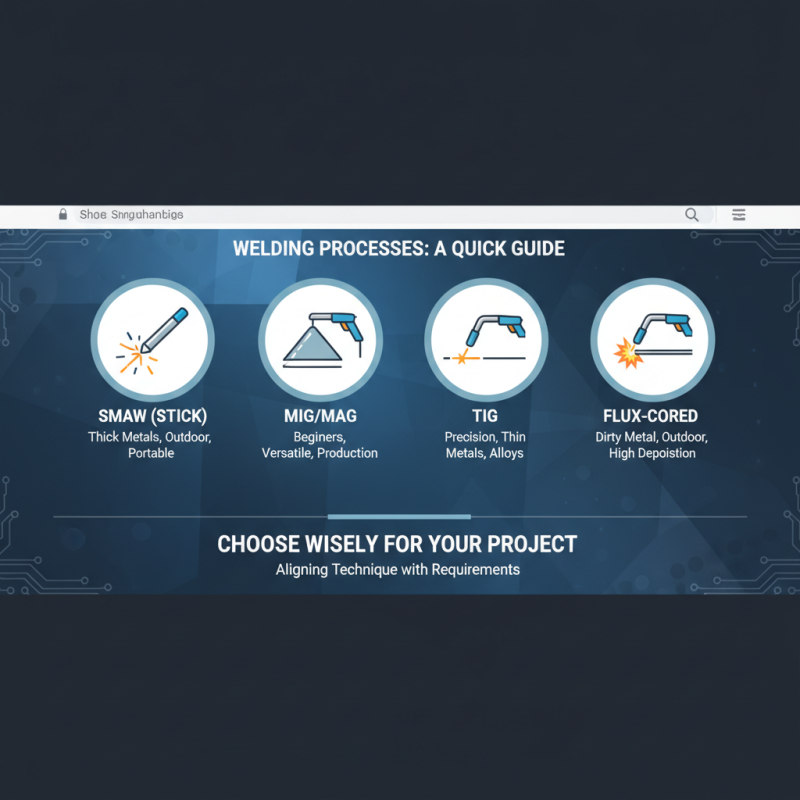

Understanding different welding processes is crucial for selecting the best welder equipment for your projects. Each welding method has its unique characteristics, advantages, and applications, making it essential to align your project requirements with the appropriate technique.

MIG (Metal Inert Gas) welding, also known as GMAW (Gas Metal Arc Welding), is known for its speed and ease of use, making it ideal for beginners and quick jobs. It utilizes a continuous wire feed and an inert gas shield to protect the weld pool from contamination. This process is particularly effective for welding thin materials and is commonly used in automotive repairs and fabrication.

On the other hand, TIG (Tungsten Inert Gas) welding offers high precision and greater control, making it suitable for welding thinner materials and critical joints. It requires a filler rod, which is manually added into the molten weld pool, allowing for intricate designs and clean finishes. Stick (SMAW) welding is another popular process, widely used for its versatility and ability to weld in various positions. It relies on a consumable electrode coated in flux, which protects the weld from contaminants, making it suitable for outdoor and heavy-duty applications. Lastly, Flux-Cored Arc Welding (FCAW) is similar to MIG but uses a tubular wire filled with flux. This method is particularly advantageous for welding thick materials and in windy conditions, where shielding gas may be less effective. Each of these processes can cater to different project needs, making it essential to consider the specific requirements before choosing your equipment.

When selecting welder equipment for your projects, understanding key specifications is crucial for achieving optimal welding performance.

Amperage is one of the primary factors to consider; it determines the heat output and penetration ability of the welder.

Industry standards generally recommend that for most applications, a welder should provide at least 30 to 300 amps, depending on the materials being welded. For instance, thinner materials may only require 30-70 amps, while thicker steel components typically necessitate a higher amperage range. A welder's amperage rating directly affects its performance, so ensuring it matches the requirements of your specific projects is essential.

Another critical specification is the duty cycle, expressed as a percentage that indicates how long a welder can operate continuously before it needs to cool down. Most welding processes operate at a 10-minute cycle, with common duty cycles ranging from 20% to 60%.

For example, a welder with a 60% duty cycle can operate for six minutes uninterrupted and needs four minutes to cool down. Selecting a welder with an appropriate duty cycle is vital for maintaining efficiency, especially for longer projects. According to industry data, welders with a higher duty cycle are often preferred in professional environments as they can sustain longer operational periods, resulting in increased productivity.

Output voltage also plays a significant role in welding quality. The voltage affects arc stability and penetration, with higher voltages generally allowing for a smoother arc and less spatter. Typical welding machines offer output voltages ranging from 20V to 40V, and selecting the appropriate voltage setting for the workpiece thickness and type is key to achieving a clean weld. Comprehensive assessments incorporating these specifications will ultimately facilitate informed decision-making in the selection of welder equipment tailored to specific project demands.

When selecting the right welder equipment for your projects, understanding the type of materials and their thickness is crucial. The American Welding Society (AWS) reports that different materials require specific welding processes and techniques to achieve optimal results. For instance, thin materials, such as sheet metals with a thickness of 1/8 inch or less, often benefit from MIG welding due to its speed and ease of use. In contrast, thicker materials, such as structural steel over 1/4 inch, may require deeper penetration provided by TIG or Stick welding to ensure strong, reliable joints.

Moreover, the material type plays a significant role in determining the ideal welding technique. According to a study published by the Welding Research Council, materials like aluminum and stainless steel present unique challenges due to their different thermal properties and melting points. Aluminum, being highly conductive, necessitates high travel speeds and specialized filler materials for effective welding. On the other hand, when working with stainless steel, maintaining a low heat input is key to preventing warping and heat-affected zones. Thus, understanding these material characteristics not only influences the choice of welding equipment but also ensures the quality and durability of the final product.

| Material Type | Thickness (mm) | Recommended Welder Type | Welding Process | Suitable Electrode/Wire |

|---|---|---|---|---|

| Mild Steel | 1-10 | MIG Welder | MIG (GMAW) | ER70S-6 |

| Stainless Steel | 0.5-6 | TIG Welder | TIG (GTAW) | ER308L |

| Aluminum | 1-8 | MIG Welder | MIG (GMAW) | ER4047 |

| Cast Iron | 5-30 | Stick Welder | SMAW | Nickel Electrode |

| Copper | 0.5-5 | TIG Welder | TIG (GTAW) | ER CuSi |

When selecting the best welder equipment for your projects, it's essential to consider not only the initial cost but also the long-term investment. While some may be tempted to choose the cheapest option available, it's important to remember that higher-quality equipment often leads to better performance and durability. This can translate into cost savings over time, as reliable tools require less maintenance and fewer replacements.

Tips: Before making your purchase, assess your project needs and frequency of use. If you plan to weld regularly, investing in a more advanced welder might be wise. Additionally, factor in the cost of consumables and maintenance, as these ongoing expenses can add up.

Another key aspect is the potential value added to your projects. A modest initial investment in high-quality equipment can yield superior results, increasing both productivity and the quality of your work. As you gain experience, the right welder can help you tackle complex tasks that may not be feasible with lower-end models.

Tips: Consider the versatility of the equipment; models that can handle various welding processes can maximize your capabilities without necessitating multiple separate purchases. This strategic approach ensures you're making a sound long-term investment while effectively managing your budget.

When selecting the best welder equipment for your projects, safety features and accessories play a crucial role in ensuring optimal protection. One of the primary safety features to consider is the welder's built-in protections, such as thermal overload and voltage control. These features help prevent equipment failure and reduce the risk of accidental injuries due to equipment malfunctions. It's essential to choose a welder that automatically shuts down in unsafe conditions, offering peace of mind while you concentrate on your work.

In addition to the welder itself, investing in appropriate safety accessories is vital. Protective gear, such as welding helmets with proper shading, gloves, and flame-resistant clothing, minimizes exposure to harmful sparks and UV radiation. Furthermore, using proper ventilation systems can significantly reduce the risk of fume inhalation. Consider additional items like fire extinguishers and first aid kits near your workspace, ensuring a comprehensive safety plan that addresses all potential hazards. Selecting equipment and accessories with safety in mind fosters a secure working environment and enhances overall productivity.