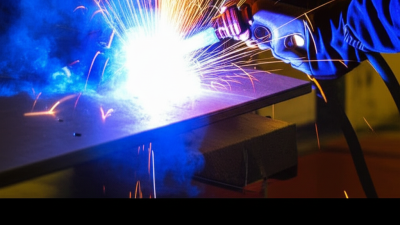

When considering welding machines for your projects, the choice can be overwhelming. Among the various options available, the Tig Welding Machine stands out for several reasons. This machine offers precision and versatility, making it ideal for both beginners and seasoned professionals.

The Tig Welding Machine allows for clean and strong welds on different metals. It is suitable for applications ranging from art pieces to industrial fabrication. However, it's crucial to recognize that mastering this machine takes time and practice. Mistakes can happen, but learning from them is part of the journey.

Overall, choosing the right welding machine can significantly impact your work. The Tig Welding Machine's benefits often outweigh its learning curve. It's not just about the equipment; it's about how you grow as a welder through your experiences with it.

TIG welding, or Tungsten Inert Gas welding, is renowned for its precision. It employs a non-consumable tungsten electrode to create a weld. This technique is ideal for thin metals, providing clean and strong welds. According to industry reports, TIG welding is preferred in aerospace and automotive applications where quality is paramount.

One major benefit of TIG welding is its versatility. It can be used on various metals including aluminum and stainless steel. A study indicates that 80% of fabricators believe that TIG welding enhances their production quality. However, it requires practice to achieve optimal results. Mistakes can lead to defects in the weld.

Tips: Focus on mastering the arc length. A shorter arc creates less heat, but too short may cause tungsten contamination. Also, ensure proper gas coverage to avoid oxidation. Regular maintenance of your equipment is essential for consistency and quality in your projects.

TIG welding also promotes a cleaner working environment. The process produces little spatter compared to MIG welding. This can lead to lower cleanup costs. Yet, the initial learning curve and greater equipment cost might deter some. Investing time in learning TIG techniques can significantly benefit long-term projects.

TIG welding machines offer unique advantages for various projects. One major benefit is precision. With a tungsten electrode, welders can focus on fine details. This enables high-quality welds on thin materials. The arc is stable, allowing for control over heat input. This reduces the risk of warping or melting.

Another appealing aspect is versatility. TIG welding works on many metals, including steel and aluminum. It’s great for projects requiring different materials. The process can be used in delicate applications, like automotive repairs. However, mastering TIG welding can be challenging. Beginners may struggle with the foot pedal and filler rod handling.

TIG welding also produces cleaner welds. This results in less post-weld cleanup, saving time. Visual aesthetics can be vital for certain projects. Additionally, because this method uses a non-consumable electrode, it has fewer spatter issues. Still, the complexity may deter some. Often, welders reflect on their techniques and seek improvement.

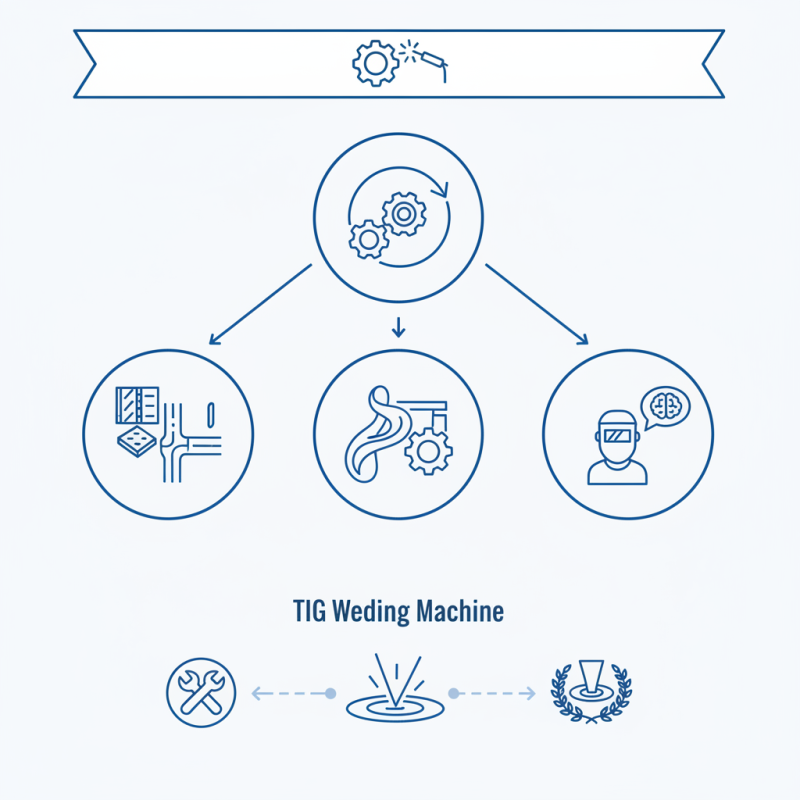

This chart illustrates the key advantages of using a TIG welding machine for various projects. Each advantage is rated based on its significance, showcasing how TIG welding excels in precision, versatility, and control, making it a preferred choice for high-quality welds.

TIG welding is essential across many industries. In aerospace, it ensures high-quality welds in materials like aluminum and titanium. The need for precision here is paramount. It's reported that over 60% of aerospace manufacturers prioritize TIG welding for structural components.

In the automotive industry, TIG welding is equally crucial. It is widely used for stainless steel exhaust systems and aluminum bodies. A report indicates that about 70% of automotive manufacturers rely on TIG for its clean, aesthetic welds. These aspects are vital where both performance and appearance matter, but the skill required is high. Mistakes can lead to costly rework.

The fabrication sector also benefits from TIG welding. It is favored for artistic metalworks and custom projects. Creative applications require a steady hand and an eye for detail. However, not all fabricators master this technique. Inconsistent results can impact reputation and quality. Ensuring consistent weld quality remains a challenge for many.

| Industry | Application | Material Used | Benefits of TIG Welding |

|---|---|---|---|

| Aerospace | Airframe welding | Aluminum, titanium | Precision and high-quality welds |

| Automotive | Exhaust systems | Stainless steel | Clean welds and reduced contamination |

| Construction | Metal structures | Carbon steel, alloy steel | Versatility and strong joints |

| Manufacturing | Fabrication of components | Copper, brass | Reduced distortion and excellent control |

| Marine | Boat construction and repairs | Aluminum, stainless steel | Corrosion resistance and aesthetically pleasing finishes |

When selecting a TIG welding machine, several factors come into play. The type of projects you have in mind is crucial. According to industry reports, 45% of welders prefer TIG for its precision. This process is ideal for thin materials and intricate designs. That’s not all; the versatility of TIG welding makes it suitable for various metals, including aluminum and stainless steel.

Another factor to consider is the machine's amperage range. Many models operate between 5 to 300 amps. This range ensures you can handle different thicknesses of materials. A report from the Welding Institute found that 70% of professionals recommend a dual-voltage option for flexibility. For beginners, though, it can be overwhelming to choose the right settings initially. This can lead to mistakes, such as improper heat input, which can compromise the weld integrity.

Portability might also impact your decision. Many TIG machines are now compact and lightweight. However, some models sacrifice power for portability. This trade-off can hinder performance in demanding applications. Understanding your specific needs will help you make better choices. Remember, it’s acceptable to reflect on your past experiences with different machines while making a decision.

When it comes to TIG welding, proper maintenance is crucial. Regularly check your tungsten electrode for wear. A dull or contaminated electrode can lead to poor performance. Replace it when necessary. Keep your torch clean. Remove any spatter or buildup that may hinder airflow. A clean torch allows you to maintain stable arcs and produce higher quality welds.

Additionally, inspect your equipment regularly. Look for any leaks, especially in hoses and connections. Even small leaks can disrupt the welding process and result in inconsistent results. Cleaning your work area is also important. A cluttered space can lead to accidents or missed components. Ensure you have all your tools in reach before starting.

Monitoring your settings is vital. Adjust the amperage according to the thickness of the material. Too much power can result in burn-through, while too little can lead to a lack of penetration. Take note of your welding environment as well. Temperature and humidity can affect metal behavior during welding. Reflection on these elements will improve your welding projects. Proper maintenance ultimately enhances the quality of your work.