Choosing the right Digital Welding Machine can be daunting. Industry expert, John Smith, once stated, "Selecting the perfect machine is crucial for success." With numerous options available, it can be overwhelming. Each machine offers different features that cater to various needs.

Welding projects vary greatly. A hobbyist may require a simple model, while a professional may need a high-performance machine. The specific materials and techniques you plan to use greatly influence your choice. Portability may also be a factor; some machines are more convenient than others.

It's important to reflect on your requirements before purchasing. Consider your skill level and budget. Sometimes, the best machine isn't the most expensive one. Finding a balance between quality and cost is essential. It's easy to get caught up in features that may not be necessary for your work. A little introspection on your actual needs can lead to a more informed decision.

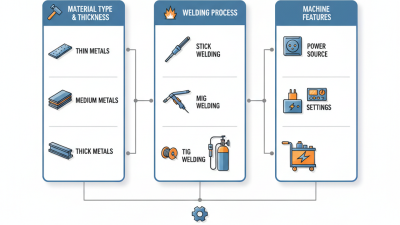

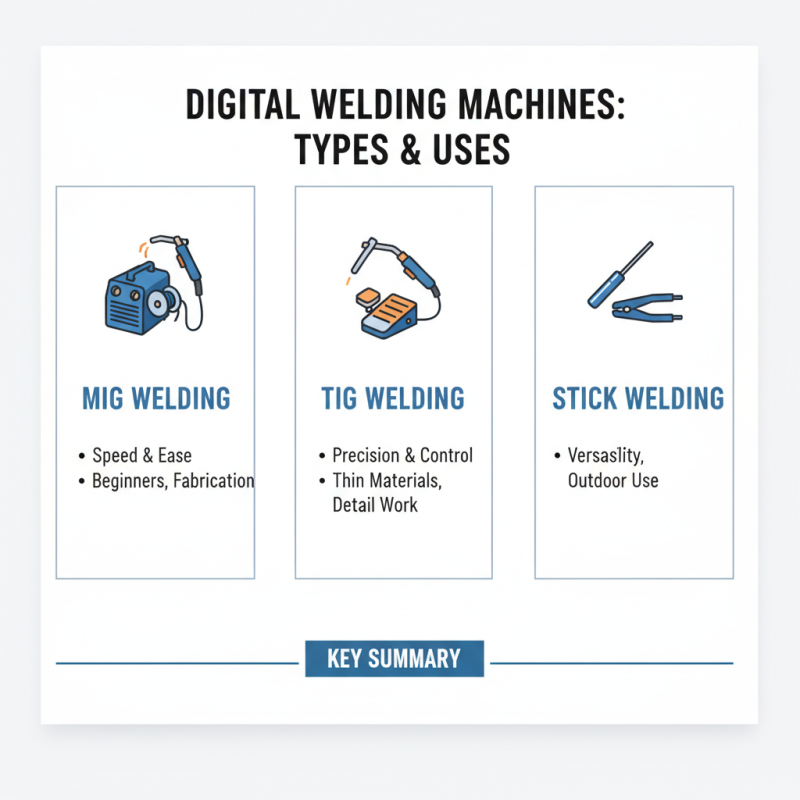

When looking for a digital welding machine, it’s essential to understand the different types available. Three primary categories stand out: MIG, TIG, and Stick welding machines. Each type serves specific applications. MIG machines are often favored for their speed and ease of use. They are ideal for beginners and fabrication work. TIG machines provide more control and precision, making them suitable for detailed work and thinner materials. Stick welding offers versatility, especially in outdoor settings.

According to industry reports, the global welding equipment market size was valued at over $23 billion in 2021. The growth is projected to continue as advancements in digital technology enhance welding processes. Many professionals report a notable reduction in welding defects with digital machines. However, the initial learning curve can be a challenge. Users often reflect on the complex controls and settings that may overwhelm new welders. Selecting the right type depends heavily on your specific needs and experience level. Understanding these differences can lead to more efficient and successful welding projects.

When choosing a digital welding machine, several key features matter. Look for the power output range. A versatile machine can handle various materials and thicknesses. This range affects your ability to perform different welding tasks effectively. Consider the type of welding processes it offers. Some machines excel in MIG, while others are better suited for TIG. Knowing your specific needs is crucial here.

Control features are also essential. An easy-to-read digital display can simplify your adjustments during projects. A simple interface saves time and reduces mistakes. Portability might be overlooked, but it impacts how and where you can work. A lightweight design with a sturdy build can make a significant difference. Think about the duty cycle as well. A machine with a higher duty cycle allows for longer work periods without overheating.

It's also worth reflecting on the machine's safety features. Overheating protection and automatic shutoff can prevent accidents. Do you need a machine that includes such features? Lastly, consider the warranty and customer service. Sometimes, a lower price might compromise quality. Be cautious about this. Your investment should lead to reliable performance and support when challenges arise.

Choosing the right digital welding machine requires an understanding of your skill level. If you are a beginner, opt for user-friendly models with basic features. Look for machines with clear instructions and safety features. These will help you build confidence as you learn.

Consider the type of projects you plan to undertake. Lightweight machines work well for small repairs. If you are tackling larger projects, you may need a more robust option. Think about the materials you will use. Different machines handle different metals. Researching these details can save you time and frustration later.

Don’t forget to reflect on your long-term goals. Are you planning to expand your skills? If so, consider a machine with advanced features. However, you might be overwhelmed by complex options. Balancing simplicity and functionality is key. Take your time to choose wisely.

When budgeting for a digital welding machine, consider various factors beyond just the initial purchase price. According to industry reports, nearly 30% of users overlook operational costs. These costs include electricity, maintenance, and potential repairs. An effective budgeting plan accounts for these long-term expenses.

Tips: Assess your expected usage frequency. Higher usage may justify investing in premium models. Also, inspect warranty offers; they can save you money in repairs later.

Think about training expenses as well. If your team lacks skills, additional investment in training is essential. Interestingly, 40% of companies reported challenges due to inadequate training on new machines. This can lead to inefficiency and wasted materials.

Tips: Invest in basic training with your purchase. Online courses or workshops often provide valuable insights. Allocate funds in your budget for these educational resources to maximize your machine's capabilities.

Balancing upfront costs and long-term expenses is vital. Cheap machines can lead to frequent breakdowns. Eventually, this may exceed the cost of robust models. Building a holistic budget ensures you choose a machine that meets your needs effectively.

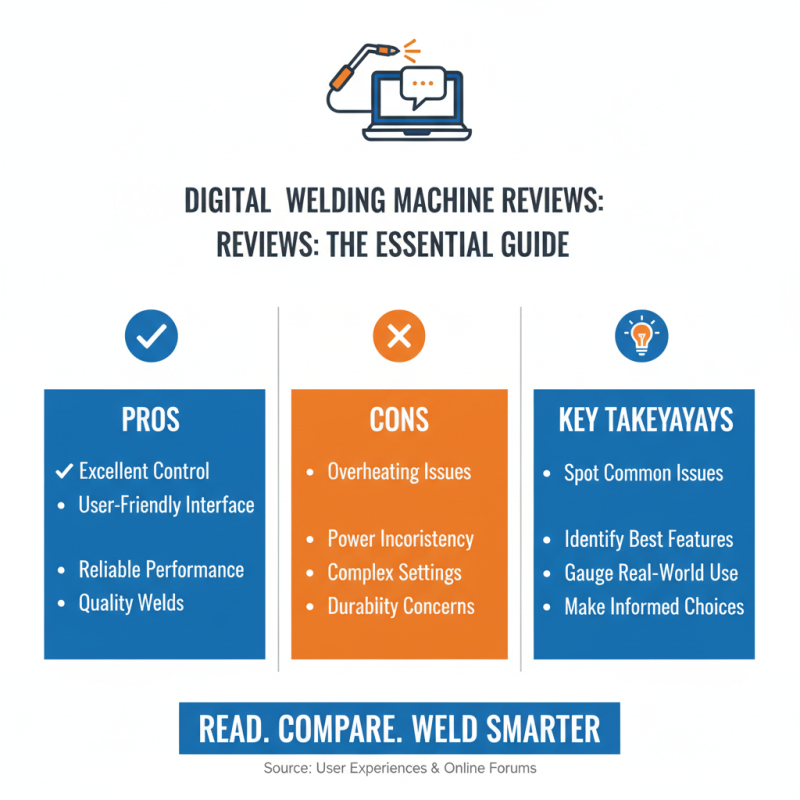

When searching for a digital welding machine, reading reviews is essential. Many users share their experiences online. They highlight both pros and cons of various machines. Reviews often reveal common issues, such as overheating or power inconsistency. Some machines are praised for excellent control features, while others struggle with user-friendliness.

Getting recommendations from professionals can also be invaluable. Experienced welders often know which machines perform best under specific conditions. They can share insights that you might not find in online reviews. It’s not uncommon for professionals to have strong opinions, sometimes differing from popular reviews. Personal preferences play a major role in their recommendations, too.

It’s important to remember that what works for one person may not work for another. Different projects require varying capabilities from a welding machine. Engaging with a community of welders can lead to meaningful discussions. Sharing experiences can clarify your needs and help narrow down your choices. Keep in mind, no machine is perfect. Thus, consider feedback carefully and reflect on how it aligns with your specific welding projects.