Choosing the right Tig Machine is crucial for any welding project. Expert John Smith states, “The right Tig Machine can transform your work.” With various options available, it’s vital to understand your needs. An unsuitable Tig Machine can lead to inefficiency.

Consider the metal types and thicknesses you will weld. Different machines perform better with specific materials. For instance, aluminum requires a machine with higher frequency. Functions vary across models; some offer more control than others. A simple stereo vs. surround sound analogy describes this well.

Buying a Tig Machine can be confusing. The sheer variety may lead to impulse purchases. Think through your projects before deciding. Buying without careful thought risks your investment. Reflect on what you truly need.

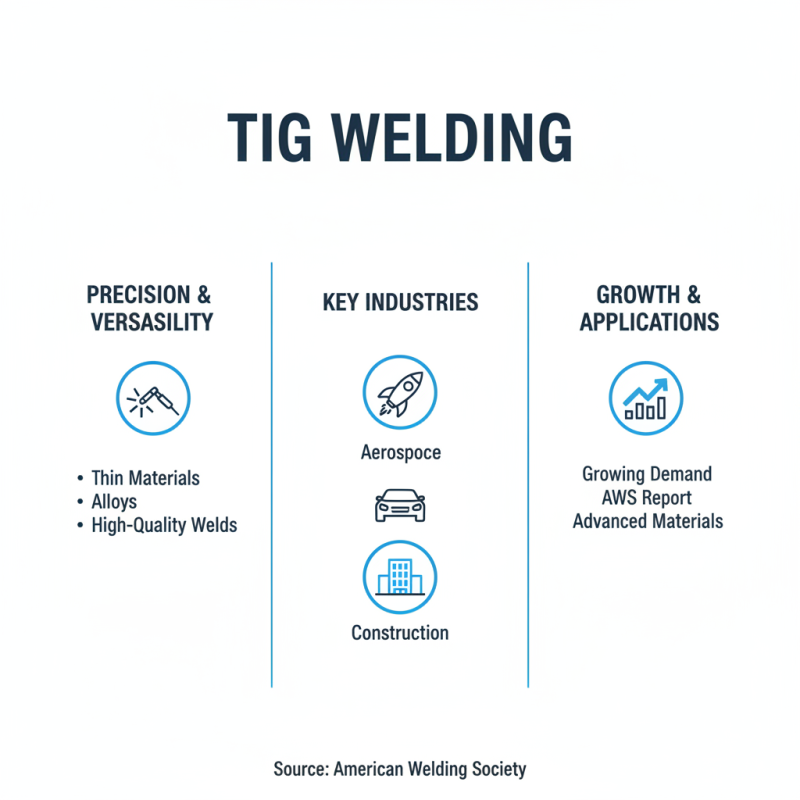

TIG welding, or Tungsten Inert Gas welding, is known for its precision and versatility. It's widely used in industries like aerospace, automotive, and construction. According to a report from the American Welding Society, TIG welding is growing, with applications in thin materials and alloys. Its ability to produce high-quality welds makes it a preferred choice.

When selecting a TIG machine, consider your specific needs. If you’re working with stainless steel, for instance, a machine with a high-frequency start can enhance your control. The American Welding Society highlights that skilled operators can improve productivity by up to 50% when using the right equipment.

Tips: Always assess the thickness of the materials you'll be welding. Using incorrect settings may result in burn-through or weak joints. Pay attention to manufacturers' specifications for amperage and duty cycle. Sometimes, it’s better to choose a machine that allows for future upgrades. Don't rush the decision; your choice can influence your overall welding quality.

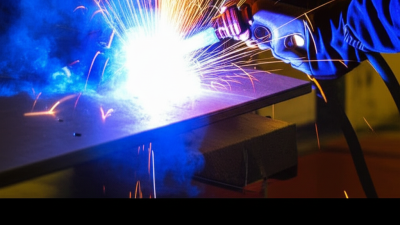

Choosing the right TIG machine can significantly impact your welding projects. It’s vital to consider the welding materials you will use. Different metals require different amperage and features. For instance, aluminum welding demands a machine with high frequency starting. On the other hand, stainless steel might work better with pulse settings for better control.

Welders should also think about portability. If you plan to move the machine often, a lightweight option may be better. However, mobility sometimes compromises power. Look for a balance that suits your workspace. Lastly, consider your skill level. Beginners may find machines with simpler settings easier to manage. Advanced welders often seek additional features for intricate tasks. Evaluate these factors carefully. It can prevent regrets in the long run.

When selecting a TIG welder, it's crucial to compare the different types available. Each type has unique features suitable for specific tasks. Some welders are portable, while others offer advanced control for intricate projects. For example, an AC/DC TIG welder is useful for both aluminum and steel welding. It gives flexibility that many hobbyists and professionals seek.

Tips: Consider your project size. A compact model works well for small repairs. Larger projects might require a heavier unit. Don't overlook features like adjustable amperage. They allow for precision tuning in your work.

Furthermore, the power source is an important factor. Some machines require a standard outlet, while others need a more robust setup. Think about your workspace and electrical capacity before making a decision. Oversized machines can become cumbersome in tight areas.

Tips: Always read user reviews. They can highlight issues not mentioned in specifications. Gather insights on reliability and performance from fellow users. Investing in a good machine is essential but choosing the right one should match your needs.

This chart compares the typical amperage range for different types of TIG welding machines. Understanding these specifications helps in selecting the right machine for your specific welding needs.

When choosing a TIG machine, certain features and specifications are crucial. Look for the amperage range; it should suit various materials and thicknesses. Machines with a range from 5 to 200 amps are common. This flexibility allows you to weld thin metal sheets and thicker materials effectively. A high-quality TIG machine typically comes with foot pedals for better control. Pedals help in adjusting the heat while keeping both hands free.

Another essential aspect is the power source. Some machines operate on AC, while others use DC. AC is often preferred for aluminum, whereas steel welding benefits from DC. Your welding projects might dictate the power type you need. Additionally, consider features like gas flow meters. They ensure the correct shielding gas flow, which affects weld quality.

Portability can be a concern too. Some machines are heavier and not meant for site work. If you’re traveling, lightweight options are better. Reflect on what you prioritize—weight, power, or versatility. Each choice has its pros and cons. Investing in a reliable TIG machine may save you time and effort in the long run. Yet, every machine has a learning curve, and mastering it takes practice and patience.

When budgeting for your TIG welding equipment, it’s crucial to understand your specific needs. Start by evaluating the type of projects you'll undertake. Consider the materials you’ll weld and the thickness. These factors will influence the machine you need. A basic model may suffice for light tasks, while heavier work requires advanced features.

Prepare for additional costs beyond the machine itself. Don’t overlook expenses like tungsten electrodes, filler rods, and gas. These materials can add up quickly. It's wise to set aside funds for safety gear, including gloves and helmets. Prices can vary greatly, so research thoroughly. Sometimes, opting for a more affordable machine might lead to unexpected limitations. You may find yourself needing upgrades sooner than anticipated, which can disrupt your budget. It's a learning process that requires careful thought.

| TIG Machine Type | Amperage Range | Weight (lbs) | Price Range | Best For |

|---|---|---|---|---|

| Portable TIG Welder | 20-200 Amps | 35 | $500 - $800 | Hobbyists and Light Fabrication |

| Industrial TIG Welder | 20-300 Amps | 100 | $1,500 - $3,000 | Professional Welding |

| Multi-Process Welder | 20-250 Amps | 60 | $700 - $1,500 | Versatile Applications |

| High-Frequency TIG Welder | 5-300 Amps | 75 | $1,200 - $2,500 | Precision Welding |