Electric welding plays a crucial role in various industries. It is an efficient way to join materials. The global electric welding market is projected to reach USD 25 billion by 2027, according to a recent report. This undeniable growth highlights its importance in construction, automotive, and manufacturing sectors.

There are different types of electric welding techniques, each with specific applications. These include MIG, TIG, and Arc welding. Each method has its own advantages and disadvantages. For example, TIG welding offers precise control but can be slower than MIG welding. It’s important to consider these factors when choosing a type.

Despite the advancements, challenges remain in electric welding. Issues like weld quality and operator skill can impact outcomes. Moreover, the rising demand for automated solutions raises the bar. As industries evolve, so must the techniques and training associated with electric welding. Understanding these nuances is vital for success.

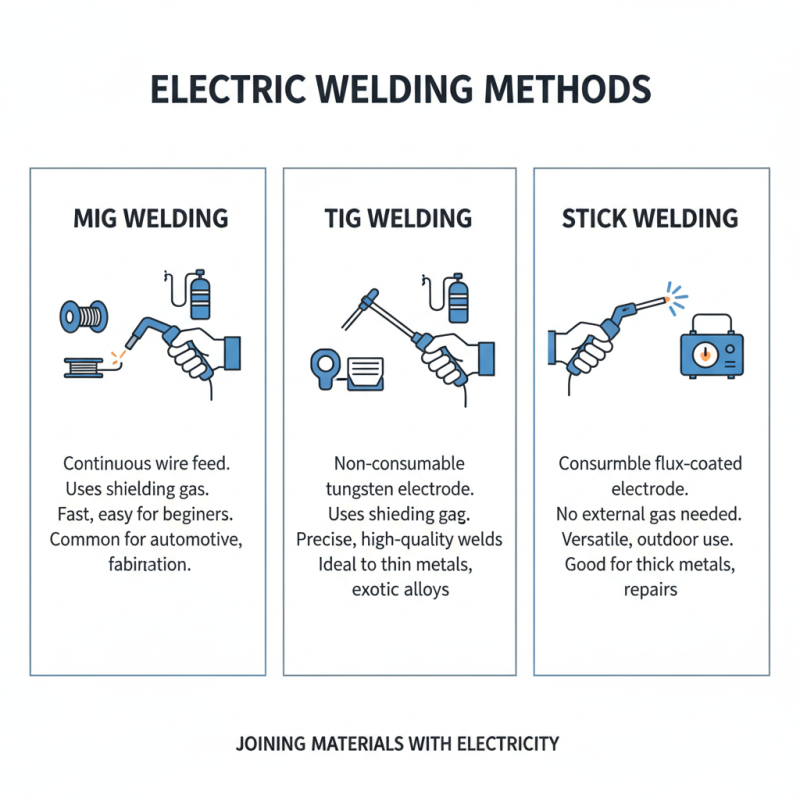

Electric welding encompasses several methods for joining materials. Each method has its unique characteristics and applications. Common types include MIG, TIG, and stick welding.

MIG welding uses a continuous wire feed to create a strong bond quickly. It's suitable for thin materials. This method is often favored for its speed and ease of use. However, it may require a clean surface for optimal results. Otherwise, the weld may not hold properly.

TIG welding provides greater control and precision. With this method, a non-consumable tungsten electrode is used. It allows for intricate designs and detailed work, ideal for thin metals. Yet, it can be complex, demanding skilled hands. Stick welding, while older, is robust and versatile. It’s effective in outdoor conditions. Still, it can create more spatter. Each technique holds its own strengths and challenges in the electric welding landscape.

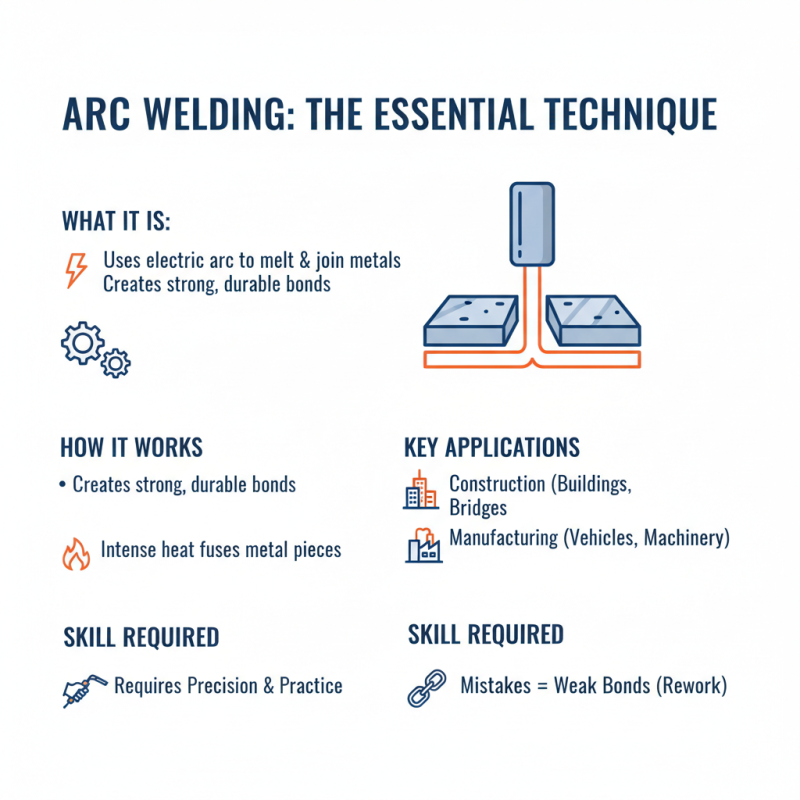

Arc welding is a crucial technique in the field of electric welding. It uses an electric arc to melt metal, joining pieces together. This process is widely applied in construction and manufacturing. The intense heat from the arc allows for strong, durable welds. However, it requires skill to master. Mistakes can lead to weak bonds, which may necessitate reworking the welds.

In arc welding, different methods can be employed. Shielded Metal Arc Welding (SMAW) is popular for its simplicity. Gas Metal Arc Welding (GMAW) is favored for speed. Both methods have unique advantages and challenges. For example, SMAW can be messy, generating slag that must be cleaned. Meanwhile, GMAW requires a continuous wire feed, which can complicate setups.

Operators often face tough decisions regarding equipment and techniques. The right choice hinges on the project and environment. Testing different methods is key to finding the best fit. Each approach comes with a learning curve, making practice essential. Disregarding safety measures can lead to accidents, an unfortunate reality in this trade. Understanding these nuances is vital for success in electric welding.

MIG (Metal Inert Gas) welding is a widely used technique in various industries. It employs a continuous solid wire electrode fed through a welding gun. This wire creates an arc between the workpiece and the electrode, generating heat to melt the metal. The process is efficient and versatile, ideal for thin to medium-thick materials.

In recent years, industry reports show that MIG welding accounts for over 30% of all welding operations globally. This popularity stems from its speed and adaptability. Operators appreciate its ease of use, especially in automatic processes. However, not all technicians master this method. Challenges in settings, such as voltage and gas flow, can lead to defects in weld quality.

Additionally, the cost of equipment is a consideration. While initial investment can be high, the benefits in efficiency often outweigh this. Beginners may struggle to achieve perfect results. Common issues like porosity or incomplete fusion require practice and understanding. Continuous learning and skill development are crucial. The journey to mastery in MIG welding is ongoing and demands patience.

TIG welding, short for Tungsten Inert Gas welding, is a precise and versatile welding process. It uses a non-consumable tungsten electrode to produce the weld. The process requires a shielding gas, typically argon, to protect the weld area from contamination. This gas shields the molten metal, ensuring a strong and clean bond.

One notable feature of TIG welding is its ability to weld thin materials. This makes it ideal for projects involving stainless steel or aluminum. However, it requires a high level of skill. Beginners may struggle with maintaining a steady arc. Practice is crucial to mastering the technique. Distinctively, TIG welding allows for a clean finish, but it also has its challenges.

Welders must manage multiple controls during the process. The balance of speed and heat is essential for a successful weld. A welder's hand needs to be steady. This process is unforgiving if mistakes are made. Even a slight dip in the tungsten electrode can lead to defects. Thus, continuous improvement and practice are vital for mastering TIG welding.

Resistance spot welding and seam welding are essential techniques in the electric welding field. Each method has distinct advantages and applications. Resistance spot welding is primarily used for joining thin sheets of metal. This method is efficient and quick, making it ideal for high-volume production. Reports indicate that global usage of spot welding in the automotive industry ranges from 90% to 95% for body assembly.

On the other hand, seam welding offers a continuous weld along a joint. It is often used for applications requiring longer, stronger seams. Seam welding is advantageous in manufacturing tanks and containers. A study highlighted that seam welding can improve production rates by up to 40% in specific industries. However, the need for precise alignment and setup can pose challenges. Any slight deviation can lead to defects in the final product.

Each method has areas for improvement. Efficiency in resistance spot welding can decline if operators are not well trained. In seam welding, ensuring consistent heat input is crucial. A thorough analysis of both methods reveals that the choice largely depends on application specifics, production volume, and overall cost efficiency. Understanding these factors is vital for optimizing welding operations.