In recent years, the global demand for high-quality welding equipment has surged, with the TIG welding machine emerging as a critical tool in various industrial sectors. According to a report by MarketsandMarkets, the global welding equipment market is projected to reach USD 23.4 billion by 2025, with TIG welding machines gaining prominence due to their precision and versatility.

China stands at the forefront of this industry, exporting top-tier TIG welding machines that are not only at the forefront of technology but also offer exceptional reliability and performance. As manufacturers increasingly seek to enhance productivity and maintain quality standards in their operations, discovering China's premier TIG welding machines becomes essential for those aiming to stay competitive in the global market. This blog delves into the attributes that make these machines a coveted asset across industries and the reasons behind China's leading position in their manufacture and export.

In recent years, China's TIG welding machines have gained significant traction in the global market, showcasing the country's ability to blend innovation with cost-effectiveness. These machines, recognized for their precision and versatility, have been at the forefront of various industries, from aerospace to automotive. China's investment in advanced technology and manufacturing capabilities has allowed it to produce equipment that meets international standards while remaining competitively priced.

The rise of China's TIG welding technology is not just a reflection of its manufacturing power but also a shift in the global welding landscape. As industries worldwide seek reliable and efficient solutions, Chinese brands have begun to establish a strong presence. Companies that once relied on Western suppliers are now turning to Chinese manufacturers for high-quality machines that offer enhanced performance and durability. This trend highlights a growing trust in Chinese engineering, paving the way for these welding machines to become indispensable in workshops and production lines around the world.

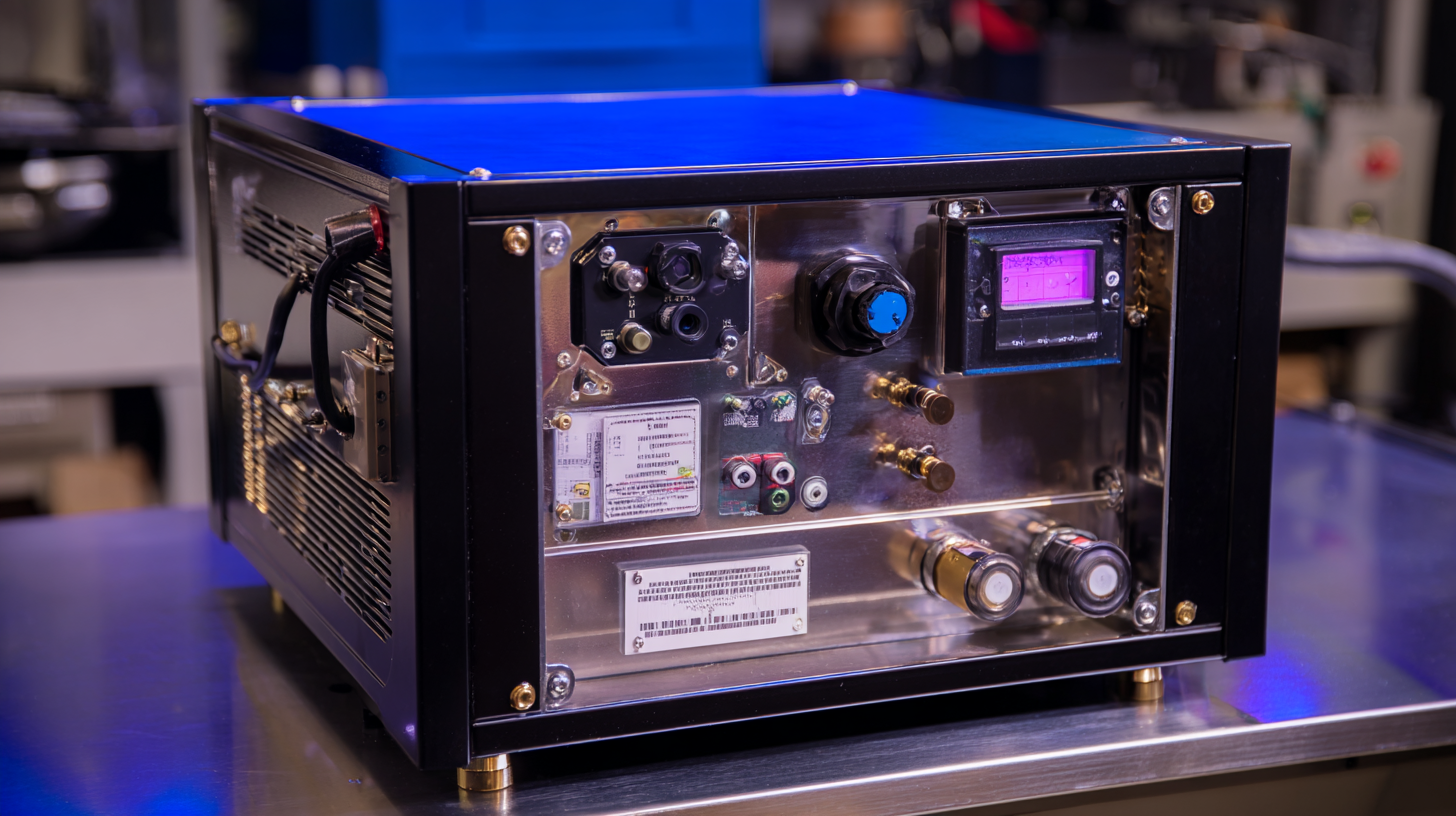

China has established itself as a leader in the production of TIG welding machines, thanks to its commitment to innovation and state-of-the-art technology. One key feature that sets Chinese TIG welders apart from their competitors is their precision engineering, which allows for clean and accurate welds. The integration of advanced inverter technology enhances efficiency and reduces energy consumption, making these machines not only powerful but also environmentally friendly. Furthermore, many models come equipped with digital interfaces and adjustable settings, enabling welders to tailor their processes to specific materials and applications.

China has established itself as a leader in the production of TIG welding machines, thanks to its commitment to innovation and state-of-the-art technology. One key feature that sets Chinese TIG welders apart from their competitors is their precision engineering, which allows for clean and accurate welds. The integration of advanced inverter technology enhances efficiency and reduces energy consumption, making these machines not only powerful but also environmentally friendly. Furthermore, many models come equipped with digital interfaces and adjustable settings, enabling welders to tailor their processes to specific materials and applications.

Another standout characteristic of Chinese TIG welding machines is their versatility. Designed to handle a wide range of materials, including stainless steel, aluminum, and exotic metals, these welders cater to various industries, from automotive to aerospace. Their robust build quality ensures durability and reliability in different working conditions, minimizing downtime and maintenance costs. As the China Industrial Robotics market continues its projected growth, the expansion of advanced welding technologies will further enhance the capabilities of manufacturers, marking a new era of efficiency and global excellence in welding solutions.

When it comes to welding technology, China has emerged as a leader in producing high-quality tig welding machines that embody quality and innovation. The country’s manufacturers have invested significantly in research and development, ensuring that their equipment meets global standards and satisfies the evolving needs of various industries. This commitment to excellence not only enhances productivity but also guarantees safety and efficiency, making Chinese tig welding machines a preferred choice among professionals worldwide.

The driving forces behind this evolution are a blend of skilled craftsmanship and advanced technology. Chinese manufacturers leverage modern technologies, such as automation and smart diagnostics, to improve the functionality and reliability of their welding machines. Furthermore, collaboration with global industry experts fosters an environment of continuous improvement and innovation. This dynamic approach has resulted in machines that are not only powerful but also versatile, accommodating a range of welding applications while minimizing energy consumption and operational costs. As a result, China stands at the forefront of the welding industry, continuously pushing the boundaries of what is possible in welding technology.

| Model | Power (kW) | Welding Current (A) | Weight (kg) | Features |

|---|---|---|---|---|

| CT-200A | 6.5 | 20-200 | 28 | IGBT Technology, Adjustable Power |

| TIG-250P | 8.0 | 10-250 | 32 | High Frequency Start, Pulse Function |

| WeldMaster 300 | 10.0 | 10-300 | 35 | AC/DC, Touch Start |

| ProTIG 180 | 5.0 | 15-180 | 25 | Compact Design, Synergic Control |

| EliteTIG 400 | 12.0 | 20-400 | 45 | Digital Display, Overload Protection |

In recent years, Chinese brands have made significant strides in global markets, particularly in the field of TIG welding machines. One standout success story is the rapid expansion of a well-known Chinese manufacturer that has positioned itself at the forefront of innovation and quality. By leveraging advanced technology and rigorous testing standards, this brand has successfully entered several international markets, rapidly building a reputation for reliability and performance. Customers in various industries, from automotive to aerospace, have turned to these machines for their exceptional welding capabilities.

Another compelling narrative comes from a partnership between a Chinese TIG welding machine manufacturer and an international construction firm. This collaboration not only enhanced the local production capabilities but also introduced state-of-the-art welding technology that streamlined operations and improved final product quality. The impact of this partnership has been profound, as it resulted in significant cost savings and increased efficiency, ultimately enabling the construction firm to compete effectively on a global scale. As Chinese brands continue to showcase their products worldwide, their ability to adapt and cater to diverse market needs will undoubtedly pave the way for future success in the international arena.

The landscape of welding technology in China is rapidly evolving, driven by advancements in laser processing equipment. According to industry reports, the global laser welding market was valued at approximately $23.75 billion in 2022 and is forecasted to grow from $24.73 billion in 2023 to an impressive $34.18 billion by 2030. This growth is influenced by various technological types such as fiber lasers, CO2 lasers, solid-state lasers, and others, which are gaining traction across multiple applications, including cutting, welding, marking, and engraving.

China's leadership in this arena is further reinforced by its significant market players, known for their advanced production technologies and automation capabilities. The market dynamics are interesting, especially in the wake of the COVID-19 pandemic, which forced companies to adapt swiftly to new market demands and challenges. As a result, there has been an increased focus on innovation and R&D, propelling the industry towards a future characterized by enhanced efficiency and efficacy in welding processes. It is clear that the trends shaping China's global leadership in welding technology are rooted in strategic advancements and a commitment to excellence in manufacturing.