In the realm of metal fabrication and welding, the Gas Mig Welder has emerged as an essential tool, especially for beginners looking to hone their skills. According to the American Welding Society, the demand for skilled welders is projected to grow by 26% between 2019 and 2029, significantly outpacing the average for all occupations. This surge highlights the importance of mastering techniques with tools like the Gas Mig Welder, which is renowned for its versatility and ease of use.

As companies and individuals alike seek to enhance productivity and quality in their projects, understanding the foundational techniques associated with Gas Mig Welding becomes critical. This ultimate guide aims to equip beginners with essential tips, ensuring that they develop a solid groundwork for their welding journey while taking advantage of the growing opportunities in this dynamic industry.

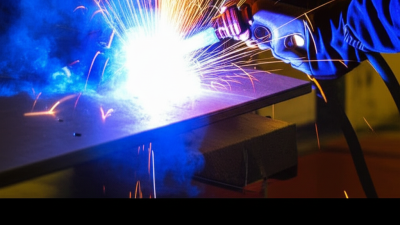

Gas MIG welding, or Gas Metal Arc Welding (GMAW), is an accessible and versatile technique, making it an ideal starting point for beginners. Understanding the basics of this process is essential for developing your skills as a welder. GMAW primarily utilizes a continuous solid wire electrode, fed through a welding gun, along with a shielding gas to protect the weld pool from contamination. This protection ensures a more stable and clean weld, which is crucial for both appearance and strength.

Recent advancements in welding technology have emphasized the importance of predicting weld characteristics to enhance outcomes. Research utilizing machine learning models has shown promise in predicting important parameters such as weld bead shape, allowing for more precise control over the welding process.

For beginners, grasping the foundational aspects of MIG welding can lead to innovative approaches and improved techniques, especially as new technology plays an increasing role in the field. By starting with gas MIG welding, novice welders can easily adapt to a variety of projects, from metal art to practical repairs, while harnessing emerging technologies to elevate their craftsmanship.

Gas MIG welding, or Metal Inert Gas welding, is a highly efficient process favored by many beginners due to its ease of use and versatility. To get started, having the right tools and equipment is essential. A reliable gas MIG welder is the cornerstone of your setup. According to the American Welding Society, around 50% of all welding performed in the U.S. is MIG welding, highlighting its popularity and demand in various industries, from automotive to construction.

In addition to the welder, you’ll need a source of shielding gas, typically a mix of argon and carbon dioxide for effective arc stability and penetration. Protective gear is also a must; a well-fitted welding helmet with appropriate lens shade protects your eyes from harmful UV rays, while gloves and fire-resistant clothing safeguard your skin.

Industry reports indicate that inadequate personal protective equipment (PPE) contributes to over 30% of welding-related injuries. Thus, investing in high-quality gear not only enhances safety but also ensures a better quality of work, making every welding project a success.

Gas MIG welding is a versatile technique that can be mastered with practice and understanding of key methods. As a beginner, focusing on the basics can make a significant difference in your welding quality.

One essential technique is learning the proper gun angle. Holding the MIG torch at a 15 to 20-degree angle can enhance the weld penetration and provide better control over the arc.

Another critical aspect is speed and travel technique. Moving the torch too quickly can result in weak welds, while going too slow can cause excessive melting. Aim for a steady, consistent movement to achieve an optimal bead. Remember, practice is key; try welding on scrap materials to refine your technique without the pressure of a final project.

Finally, control your wire feed speed for better consistency in your welds. A common tip is to adjust the feed rate according to the thickness of the material you are welding. For thinner materials, a slower feed rate may be more effective, while thicker materials may require a faster feed to maintain a strong weld. By mastering these techniques, beginners can build a solid foundation in Gas MIG welding.

Gas MIG welding, often preferred for its versatility and cleaner finish, presents unique challenges for beginners. One significant issue is achieving proper gas coverage, which is crucial for preventing oxidation. According to a report by the American Welding Society, improper gas flow can lead to weld defects in up to 70% of novice welds. It's essential to calibrate your gas flow settings before getting started; generally, a flow rate between 20-25 cubic feet per hour (CFH) works well for most applications.

Gas MIG welding, often preferred for its versatility and cleaner finish, presents unique challenges for beginners. One significant issue is achieving proper gas coverage, which is crucial for preventing oxidation. According to a report by the American Welding Society, improper gas flow can lead to weld defects in up to 70% of novice welds. It's essential to calibrate your gas flow settings before getting started; generally, a flow rate between 20-25 cubic feet per hour (CFH) works well for most applications.

Another common challenge is mastering the right technique for wire feeding. Inadequate tension or a misaligned contact tip can lead to inconsistent welds and erratic arcs. The Welding Equipment Manufacturers Association indicates that nearly 60% of novice users resort to troubleshooting arc interruptions, which often stem from feed issues. To mitigate this, beginners should practice adjusting the tension on the wire feed roller and ensure that the contact tip is clean and appropriately sized for the filler wire. Engaging in these best practices can significantly enhance the quality of any MIG weld, setting a strong foundation for more complex projects.

Safety is paramount when it comes to gas MIG welding, especially for beginners who may not yet be familiar with the inherent risks of the process. According to the Occupational Safety and Health Administration (OSHA), over 50% of welding-related injuries occur due to improper handling of equipment and a lack of understanding of safety protocols. As such, wearing appropriate personal protective equipment (PPE) is crucial. This includes a welding helmet with the correct shade lens, gloves that can resist heat, and flame-resistant clothing to protect against sparks and spatter.

Another critical safety precaution is ensuring adequate ventilation in the workspace. The American Welding Society (AWS) reports that inadequate ventilation can lead to dangerous levels of fumes and gases, which can cause long-term health problems. Beginners should use exhaust fans or work outdoors if possible, as this helps to mitigate the risk of inhaling harmful substances. Additionally, a well-organized workspace free from clutter can help prevent accidents, such as tripping over equipment or exposure to open flames, reinforcing the importance of both safety awareness and proactive preventive measures in gas MIG welding practices.