In today's rapidly evolving industrial landscape, the significance of advanced welding technologies cannot be overstated, and at the forefront of this innovation lies the TIG Machine. Hailing from China's most reputable manufacturing plants, these machines have revolutionized the way various industries approach welding tasks, offering unmatched precision and versatility.

Whether in automotive, aerospace, or construction sectors, the unique capabilities of TIG machines enable professionals to achieve stunning results and ensure high-quality seams. As industries continue to embrace modernization, understanding the innovative applications of these powerful tools is essential. This blog will delve into the transformative impact of TIG machines across multiple sectors and provide valuable insights for anyone looking to enhance their welding processes through the latest technological advancements.

TIG (Tungsten Inert Gas) welding has become increasingly vital in aerospace manufacturing processes due to its precision and versatility. This advanced technique is particularly beneficial for fabricating lightweight and complex components commonly found in aircraft and spacecraft. With a strong focus on ensuring structural integrity and minimizing defects, manufacturers rely on the best TIG machines that provide superior control over welding parameters, resulting in higher quality welds that can withstand extreme conditions.

TIG (Tungsten Inert Gas) welding has become increasingly vital in aerospace manufacturing processes due to its precision and versatility. This advanced technique is particularly beneficial for fabricating lightweight and complex components commonly found in aircraft and spacecraft. With a strong focus on ensuring structural integrity and minimizing defects, manufacturers rely on the best TIG machines that provide superior control over welding parameters, resulting in higher quality welds that can withstand extreme conditions.

When it comes to optimizing TIG welding in aerospace applications, consider investing in a machine with adjustable pulse settings. This feature allows for better heat management, especially when working on thin materials that are prone to warping. Additionally, ensure that the machine supports various tungsten electrode sizes, as different project requirements may call for specific welding electrode choices to enhance performance and achieve optimal results.

Moreover, always prioritize the use of inert gases with high purity levels to prevent contamination during the welding process. This not only improves the overall strength of the weld but also enhances the durability of aerospace components. Staying updated on the latest TIG welding technologies can significantly impact efficiency and quality, helping manufacturers meet the rigorous demands of the aerospace industry.

The Role of TIG Welding in Automotive Component Production and Quality Assurance

TIG welding, known for its precision and versatility, plays a pivotal role in the automotive industry, particularly in the production of high-quality components. With the increasing demand for lightweight and durable materials, manufacturers rely on TIG welding to join aluminum, titanium, and other advanced alloys effectively. These materials are essential for enhancing vehicle performance and fuel efficiency, making TIG welding an indispensable process in automotive engineering.

When employing TIG welding in automotive component production, ensuring optimal settings is crucial. Here are some tips for achieving high-quality welds: First, always clean the surfaces thoroughly before welding to remove any contaminants that could compromise the joint. Second, use the right filler material that matches the base metals to ensure strong fusion and minimize defects. Lastly, maintain a consistent and appropriate travel speed for uniform penetration and bead appearance.

Quality assurance is paramount in automotive manufacturing, and TIG welding contributes significantly to this by allowing for visual inspection of the welds. Inspectors can easily check for defects such as porosity or inconsistent penetration, enabling manufacturers to uphold stringent quality standards. For those involved in the process, investing time in training and skill development can further enhance the reliability and efficiency of TIG welding, ensuring that automotive components meet both safety and performance criteria.

This chart illustrates the percentage distribution of TIG welding applications in different industries, highlighting its significant role in automotive component production, which accounts for 35% of usage. Other industries, such as aerospace and manufacturing, follow with notable applications.

TIG welding, or tungsten inert gas welding, is increasingly recognized for its precision and reliability, making it an essential technique in the shipbuilding industry. This advanced welding method employs a non-consumable tungsten electrode to produce high-quality, clean welds, which is particularly vital in the construction of vessels subjected to severe marine conditions. The ability to control heat input and create visually appealing weld seams is crucial when fabricating components for ships, where structural integrity and durability are of utmost importance.

In shipbuilding, the enhanced durability achieved through TIG welding directly translates to longer-lasting vessels that can withstand the harsh maritime environment. The process allows for the welding of a variety of metals, including aluminum and stainless steel, enabling manufacturers to innovate while adhering to stringent safety standards. Additionally, the low heat input minimizes warping and thermal distortion, ensuring that the assemblies maintain their designed specifications throughout their service life. With an emphasis on quality and resilience, TIG welding stands out as a pivotal technique that drives advancements in shipbuilding, reflecting the industry's continuous pursuit of excellence.

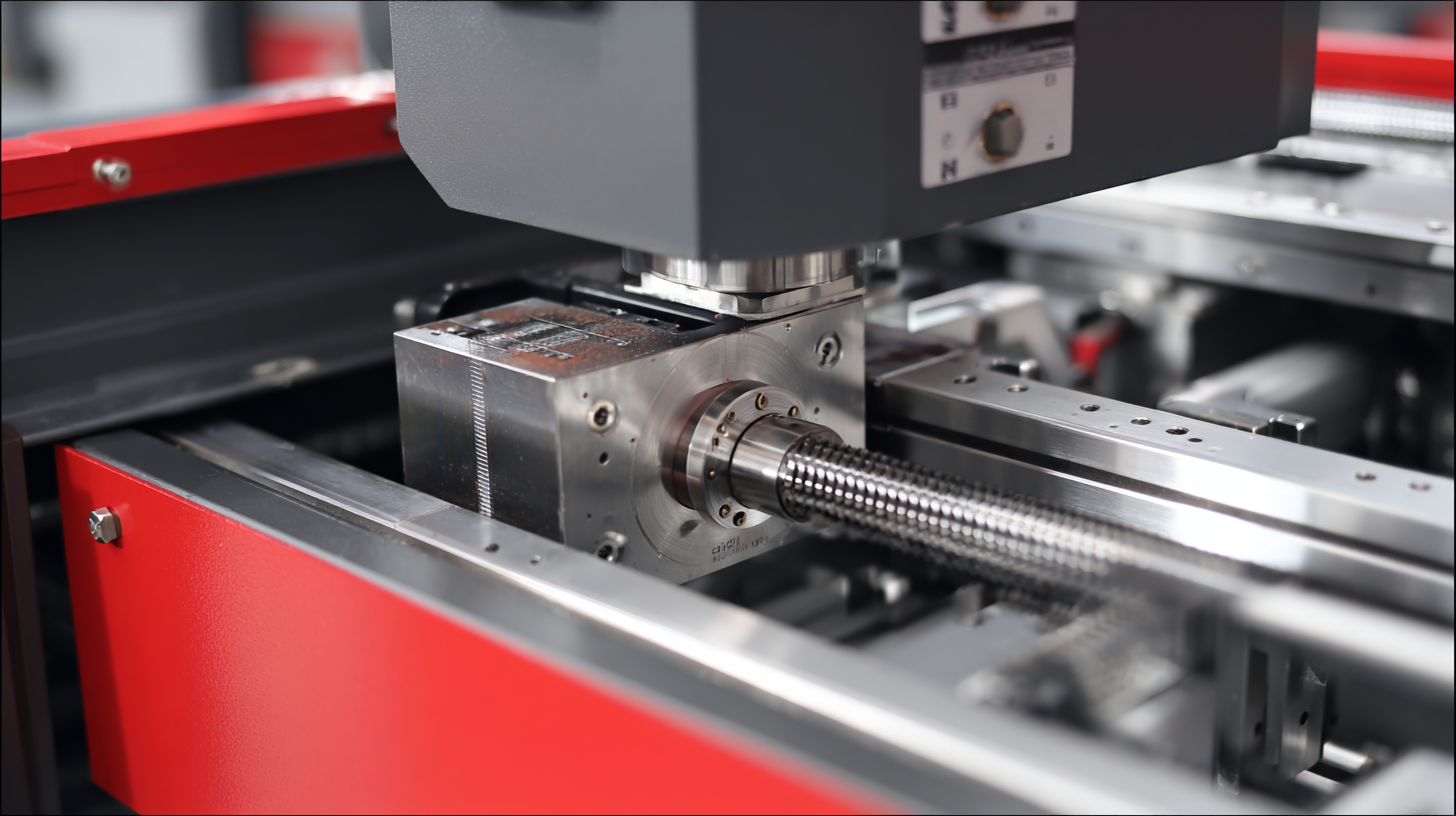

When selecting a TIG welding machine for industrial fabrication, several best practices can ensure optimal performance and efficiency. First, consider the material types and thicknesses that will be welded. Different machines cater to various materials such as aluminum, stainless steel, or carbon steel. Therefore, understanding the specific requirements of your projects will guide you in choosing a machine that delivers the right amperage and function, such as AC/DC capability for aluminum welding.

Additionally, evaluate the machine's duty cycle, which defines the amount of time the welder can operate before needing a cool-down period. A higher duty cycle is essential for heavy fabrication settings where continuous use is expected. Furthermore, don’t overlook the importance of machine features such as inverter technology for increased portability and energy efficiency or pulse welding functions that allow for better control over heat input, resulting in cleaner welds. Investing time in research and expert consultations can lead to a well-suited TIG welding machine that enhances productivity and quality in your industrial processes.

| Industry | Application | Material Types | Key Considerations | Best Practices |

|---|---|---|---|---|

| Aerospace | Fabrication of aircraft components | Aluminum, Titanium | Precision and lightweight requirements | Regular maintenance, high-quality consumables |

| Automotive | Exhaust system fabrication | Stainless steel, Mild steel | Heat resistance and durability | Use of TIG filler rods, proper torch angles |

| Construction | Welding of steel structures | Carbon steel, Alloy steel | Structural integrity and weld strength | Preheat when necessary, inspect welds |

| Art and Sculpture | Metal art creations | Bronze, Copper | Aesthetic quality and fine details | Experiment with torch settings, good ventilation |

| Energy | Pipeline construction | High-strength steel | Safety standards and pressure considerations | Use of quality equipment, thorough inspections |

When it comes to importing and exporting TIG welding equipment, understanding the key industry certification requirements is crucial for compliance and market access. Organizations such as the American National Standards Institute (ANSI) and the International Organization for Standardization (ISO) set the benchmark standards that manufacturers must adhere to in order to ensure the quality and safety of their products. For instance, ISO 9011 certification outlines the requirements for quality management systems, ensuring that equipment meets stringent production standards. Recent industry reports from MarketsandMarkets estimate that the global TIG welding equipment market is projected to reach $3.4 billion by 2025, driven by advancements in technology and increasing demand across sectors such as aerospace and automotive.

Moreover, countries often have specific certifications for TIG welding equipment related to safety and environmental regulations. In the European Union, CE marking is mandatory, indicating conformity with health, safety, and environmental protection standards. Compliance with these certifications not only facilitates smoother trade but also helps companies minimize legal risks. As competition intensifies, adhering to these key certifications not only acts as a differentiator but also enhances the credibility of brands in the global marketplace. Understanding these requirements can significantly impact the success of businesses operating in the welding industry.