In the realm of welding, mastering SMAW arc welding techniques is essential for both beginners and seasoned professionals. SMAW, or Shielded Metal Arc Welding, has been a cornerstone in the welding industry, providing a versatile solution for various applications. According to welding expert John Smith, "SMAW is not just a skill; it’s an art form that combines precision with creativity." This statement encapsulates the essence of why understanding and perfecting SMAW techniques is crucial for anyone looking to excel in the welding field.

For newcomers, the learning curve can seem daunting, yet with the right guidance and practice, anyone can become proficient in SMAW arc welding. Professionals, too, can benefit from revisiting fundamental techniques and exploring advanced strategies to enhance their skill set. This guide aims to bridge the gap between beginners seeking to learn the basics and professionals looking to refine their craft, ensuring that both groups can develop a comprehensive understanding of SMAW arc welding.

As we delve deeper into this subject, we will explore the critical techniques, tools, and best practices that define SMAW arc welding. By the end of this journey, readers will not only grasp the foundational principles but also appreciate the artistry involved in creating strong, precise welds that stand the test of time.

SMAW (Shielded Metal Arc Welding), also known as stick welding, is a fundamental technique employed in various industries, including construction, manufacturing, and repair. Understanding the basics of SMAW is crucial for both beginners and experienced welders. The process involves using an electric arc formed between a consumable electrode and the workpiece, which melts the electrode and fuses it with the base metal. According to the American Welding Society, approximately 40% of all welds made in industrial settings utilize SMAW, showcasing its significance and widespread application in welding practices.

The simplicity and versatility of SMAW make it an ideal choice for numerous applications. It can be used on various materials, including carbon steel, stainless steel, and cast iron, making it a staple technique in many workshops. A report by the National Center for Welding Education and Training highlights that SMAW is particularly favored in field applications due to its portability and the minimal need for equipment—qualities not shared by other welding methods like MIG or TIG welding. Moreover, the learning curve for SMAW is less steep, allowing beginners to develop essential welding skills quickly while professionals can refine advanced techniques that enhance weld quality and efficiency. Through understanding these core principles, welders can effectively leverage SMAW in their projects, whether they are just starting or seeking to expand their expertise.

When diving into Shielded Metal Arc Welding (SMAW), understanding the essential equipment and safety measures is crucial for both beginners and experienced welders. The basic tools required for SMAW include a welding machine, electrode holder, grounding clamp, and various electrodes. Additionally, personal protective equipment (PPE) is vital to ensure safety in the welding environment. A welding helmet with the appropriate filter shade protects the eyes from harmful ultraviolet (UV) and infrared (IR) radiation, while heavy-duty gloves shield the hands from heat and sparks. Long-sleeved clothing made from flame-resistant material is also recommended to minimize the risk of burns.

Safety measures extend beyond personal protection and equipment. It is imperative to work in a well-ventilated area to avoid inhaling harmful fumes generated during welding. Ensuring that the work area is free of flammable materials can prevent fires, and maintaining a clean workspace contributes to overall safety. Furthermore, understanding the properties of the electrodes being used and following proper handling techniques is important. By prioritizing the right equipment and adhering to these safety measures, welders can create a secure environment that promotes successful and efficient SMAW practices.

| Equipment | Description | Safety Measures |

|---|---|---|

| Arc Welding Machine | A power source that generates an electric arc for welding. | Ensure proper grounding, check for electrical faults. |

| Electrodes | Consumable rods used to conduct current and melt to form a weld. | Store in a dry place to prevent contamination. |

| Protective Gear | Includes helmet, gloves, and safety clothing. | Always wear appropriate protective gear to avoid burns and injuries. |

| Ventilation System | Ensures proper airflow to remove harmful fumes. | Use adequate ventilation while welding, especially in confined spaces. |

| Fire Extinguisher | Device to put out fires that may occur during welding. | Keep fire extinguishers accessible and regularly checked. |

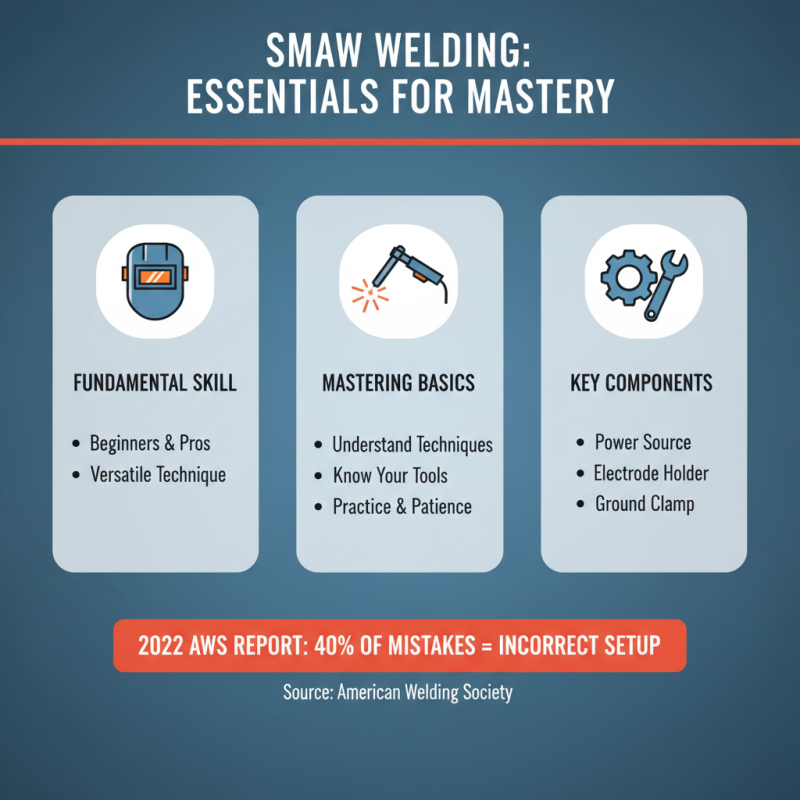

The Shielded Metal Arc Welding (SMAW) technique, also known as stick welding, remains a fundamental skill for both beginners and seasoned professionals in the welding industry. To master SMAW, it is crucial to understand the basic techniques and tools involved. Beginners should start by familiarizing themselves with the components of the welding machine, such as the power source, electrode holder, and ground clamp. A 2022 report from the American Welding Society indicates that nearly 40% of welding mistakes can be traced back to incorrect setup, emphasizing the need for a thorough understanding of the equipment.

Starting with the right electrode selection is vital. Beginners should choose mild steel electrodes, such as E6011 or E6013, which are versatile and forgiving, making them ideal for initial practice. The proper technique involves maintaining a consistent arc length and travel speed. Research suggests that a 1/8 inch arc length is optimal for good penetration and bead appearance. As welders practice, they should focus on their stance and body position to ensure stability and control, which are crucial for producing high-quality welds. A systematic approach to practicing these techniques will lay a solid foundation for advancing in SMAW and enable welders to tackle more complex projects with confidence.

Advanced SMAW (Shielded Metal Arc Welding) techniques are essential for professional welders looking to enhance their skills and improve the quality of their work.

One of the most critical advanced techniques is mastering the stringer bead, which involves a single, continuous weld without weaving. This technique provides greater control over the heat input and penetration, leading to stronger and more precise welds.

Professionals should practice this method across various joint configurations, enabling them to adapt to different welding positions and materials effortlessly.

Another advanced technique is the use of multiple passes in thick material welding. Professionals need to understand when to utilize root, fill, and cap passes for optimal bonding and strength in their welds. The key lies in balancing the heat input and ensuring proper joint preparation, as this significantly influences the final weld quality.

Additionally, experimenting with angle adjustments, travel speed, and electrode manipulation can lead to more efficient welding and reduced defects, such as undercutting or porosity.

By focusing on these refined techniques, professional welders can significantly elevate their craftsmanship and meet the demands of complex projects.

When embarking on the journey of Shielded Metal Arc Welding (SMAW), beginners and even seasoned welders can encounter a series of common mistakes that may hinder their progress. One frequent error is improper arc length, which can create inconsistent welds and reduced penetration. It's essential to maintain an appropriate distance between the electrode and the workpiece; too long an arc length can lead to a weak bead, while too short can cause sticking, damaging the electrode and the workpiece.

Another common pitfall is inadequate preparation of the work surface. Rust, paint, and dirt can significantly affect weld quality and adhesion. Ensuring that the metal surfaces are clean and well-prepared is vital for achieving strong, clean welds. Additionally, many welders underestimate the importance of proper technique, such as maintaining a steady travel speed and applying the right angle to the welding electrode. By consciously avoiding these mistakes, welders can enhance their skills and produce higher-quality results in their projects.