In the realm of manufacturing and construction, mastering stainless steel welding techniques is crucial. According to recent industry reports, nearly 70% of projects utilize stainless steel. This material offers both durability and resistance to corrosion. However, welding it requires specific skills and knowledge. John Smith, a renowned expert in stainless steel welding, states, “Precision and technique are non-negotiable for successful welds.”

The increasing demand for high-quality stainless steel products highlights the need for expert welders. Companies often struggle with issues such as improper fusion and strength inconsistencies. Misalignment during welding can lead to significant project delays. To truly excel, welders must pay attention to detail and adapt to evolving processes. Each weld should be seen as an opportunity for improvement. Mistakes can prove costly but provide valuable learning experiences.

Furthermore, the industry is continuously changing. New technology and methods emerge regularly. Staying updated is essential for maintaining a competitive edge. Investing in training and practice is crucial. Mastery of stainless steel welding is not just about technical skills; it’s about cultivating a mindset for excellence. Striving for mastery means acknowledging that there is always room for growth.

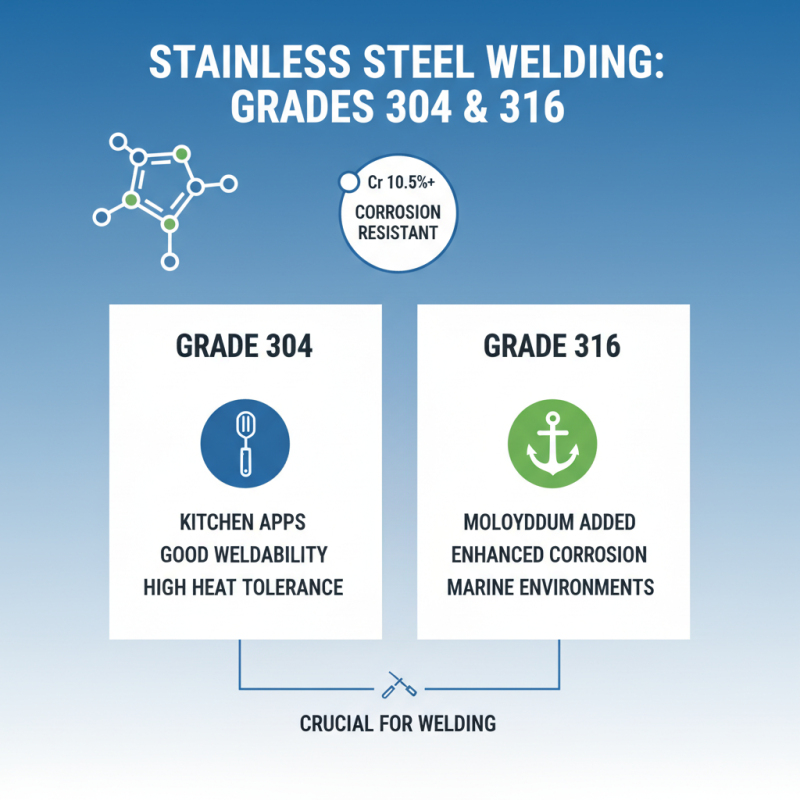

When it comes to stainless steel, understanding its properties is crucial for welding. Stainless steel is known for its corrosion resistance. This property comes from its chromium content, typically at least 10.5%. Different grades, such as 304 and 316, exhibit unique characteristics. Grade 304 is common in kitchen applications. It offers good weldability and can handle high temperatures well. Grade 316 contains molybdenum, providing enhanced corrosion resistance in marine environments.

The types of stainless steel are also important. Ferritic, a low-carbon steel, has magnetic properties. It is less ductile than austenitic stainless steel, which is non-magnetic and more ductile. Martensitic stainless steel offers high strength and hardness, but it's harder to weld. According to the American Welding Society, improper welding techniques can lead to cracking and brittleness. This highlights the importance of selecting the correct type for specific applications. A poor understanding of these properties can lead to significant project failures.

Successful welding of stainless steel requires knowledge and practice. For instance, controlling heat input is essential. Too much heat can distort the metal. Conversely, insufficient heat leads to poor fusion. It’s a delicate balance. As projects become more complex, the mistakes made can be costly. Focusing on material properties helps minimize errors. Understanding these nuances is fundamental for mastering stainless steel welding techniques.

When venturing into the world of stainless steel welding, having the right equipment is paramount. A quality welding machine is essential. It must deliver the right amount of power for your specific tasks. Data from the American Welding Society indicates that nearly 60% of welding defects are linked to improper equipment settings. Adjusting amperage can significantly impact the weld quality.

Proper safety gear cannot be overlooked. Protective gloves, helmets, and eye protection are critical. The Canadian Center for Occupational Health and Safety reports that welding poses numerous hazards, with burns and exposure to harmful fumes being common. Investing in proper ventilation is crucial for safety. A well-ventilated workspace minimizes inhalation risks.

Welding filler materials also play a vital role. Selecting the right filler ensures compatibility with stainless steel grades. It can be challenging to choose the right type, as using the wrong filler may lead to cracks. Research showcases that about 30% of weld failures stem from filler material issues. Regularly reassessing your equipment and materials fosters improvement and can prevent costly mistakes.

| Equipment | Description | Importance |

|---|---|---|

| Welding Machine | A reliable machine is essential for stainless steel welding, offering consistent power and settings. | High |

| Electrodes | Specialized rods for welding stainless steel, ensuring the best bonding and corrosion resistance. | High |

| Welding Helmet | Protects the eyes from sparks and harmful radiation during welding. | Critical |

| Protective Gear | Includes gloves, aprons, and jackets to protect against heat, sparks, and molten metal. | Essential |

| Filler Material | Used to fill the joint between the source metal pieces, enhancing strength and durability. | Important |

| Cleaners and Solvents | Required to clean the stainless steel surface to avoid contamination and ensure strong welds. | Necessary |

| Angle Grinder | Used for surface preparation, finishing, and removing imperfections on stainless steel surfaces. | Useful |

| Measuring Tools | Tools like calipers and rulers are essential for precise measurements before welding. | Very Useful |

Preparing stainless steel surfaces for welding is crucial for achieving strong, durable joints. The first step is to clean the surface thoroughly. This means removing any grease, oil, or contaminants. A wire brush or grinder can be effective, but sometimes, a chemical cleaner is necessary. Pay attention to the edges and corners where dirt can accumulate.

Next, it’s important to ensure the surface is smooth. Any rough areas can lead to poor weld penetration. Use sanding discs or flap wheels to create a consistent texture. If not done correctly, this can lead to weld defects, which might seem small but can cause problems down the line.

Lastly, consider the environment where welding will take place. Moisture can lead to oxidation, which can weaken the weld. Using a dry cloth to wipe the area can help. Even minor details matter. Skipping surface preparation may save time but increases the risk of failure. Proper preparation pays off in the long run.

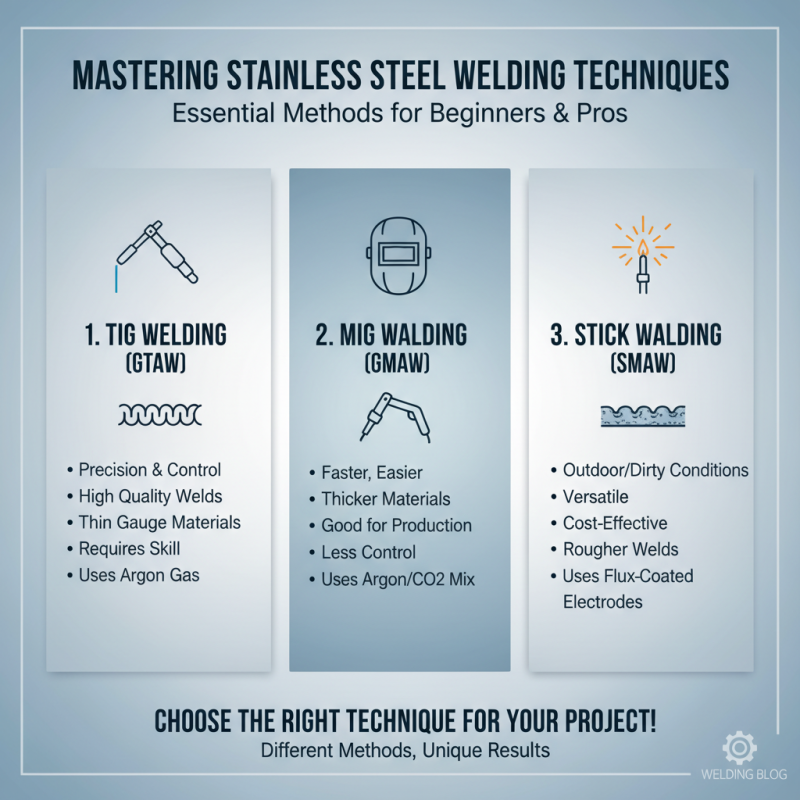

Welding stainless steel requires mastering various techniques. Whether you're a beginner or an experienced welder, understanding these methods is crucial. Different techniques produce unique results. It’s vital to choose the right one for your project.

MIG welding is popular due to its speed. It’s easy to use and great for thin materials. However, it can leave spatter that needs cleaning. TIG welding, on the other hand, offers precision. It’s ideal for intricate designs. Yet, it demands a steady hand and patience. These two methods cater to different skill levels and project needs.

Tips: Practice on scrap metal to improve technique. Experiment with different settings on your machine. Understand the heat settings; too much can warp the metal. Keep your workspace clean to avoid contamination. Don't hesitate to seek feedback from peers; it helps refine skills. Always wear proper safety gear; a mistake can be costly.

Remember, welding stainless steel isn't without challenges. You may struggle with consistency or cleanliness. Reflect on your process. Each project is an opportunity to learn and improve. With time and practice, mastering these techniques will become more attainable.

Welding stainless steel requires attention to safety. In the welding industry, approximately 20% of all accidents occur due to inadequate safety measures. Proper ventilation is essential. Fumes and gases can be harmful. Always work in a well-ventilated area or use fume extraction systems.

Protective gear is a must. This includes helmets, gloves, and flame-resistant clothing. According to industry reports, about 50% of welders experience skin irritation from exposure to harmful particles. Additionally, improper equipment can lead to severe injuries. It is crucial to regularly inspect your tools and machines.

Welding practice often emphasizes precision. However, mistakes can happen. For instance, a misaligned joint may not only weaken the weld but also pose safety risks. Continuous training and self-assessment are important. Keep learning from each project. Address vulnerabilities to improve performance and safety standards. Remember, welding isn't just about technique; it’s also about protecting yourself and your team.