In the evolving landscape of modern fabrication, mastering stainless steel welding techniques has become an essential skill for professionals in the industry. As stainless steel continues to be the material of choice for a wide array of applications — from automotive to aerospace, and architecture to custom fabrication — the demand for expert welders who can effectively handle this versatile metal is unprecedented.

This blog will delve into top strategies for honing your stainless steel welding skills, emphasizing the latest technologies, methods, and tips to improve both precision and efficiency. By understanding the nuances of stainless steel welding, fabricators can not only enhance their craft but also stay competitive in a fast-paced market. Join us as we explore the future of stainless steel welding and discover how to elevate your techniques to meet the demands of modern fabrication.

Understanding the unique properties of stainless steel is crucial for mastering welding techniques in modern fabrication. Stainless steel, particularly ferritic types, is known for its excellent corrosion resistance and mechanical properties, making it a preferred choice in various applications. Research indicates that the physical properties of ferritic stainless steels, such as their low thermal expansion and high ductility, enhance weldability and contribute to the structural integrity of welded joints. A study highlighted that the addition of elements like chromium and nickel significantly influences the performance of these metals under thermal and mechanical stress during welding.

Moreover, reports on dissimilar welding applications reveal critical insights into joint formation between materials like Inconel 718 and Austenitic stainless steels. The comparative analysis of SMAW (Shielded Metal Arc Welding) techniques demonstrates that using specific electrodes can yield improved metallurgical characteristics of the weld zone. For instance, the use of ENiCrCoMo-1 and ENiCrFe-3 electrodes has shown notable improvements in hardness and strength compared to traditional methods. By leveraging these insights and understanding the unique attributes of stainless steel, welders can enhance their techniques and achieve superior results in fabrication projects.

| Strategy | Description | Key Considerations | Benefits |

|---|---|---|---|

| Understanding Material Properties | Learn the physical and chemical properties of stainless steel for better welding outcomes. | Corrosion resistance, thermal conductivity, and melting point. | Improves weld quality and durability. |

| Pre-Welding Preparation | Clean the welding area to remove contaminants that may cause weld defects. | Use appropriate cleaning agents and methods. | Reduces the risk of failure in weld integrity. |

| Selecting the Right Filler Material | Choose a filler material compatible with the base stainless steel for optimal bonding. | Consider the specific type of stainless steel (e.g., austenitic, ferritic). | Enhances strength and elongation of the weld. |

| Proper Welding Technique | Implement techniques such as stringer beads or weaving to optimize the weld pool. | Control heat input and travel speed effectively. | Minimizes distortion and ensures uniformity. |

| Post-Weld Treatments | Utilize methods such as pickling or passivation to enhance corrosion resistance. | Select the appropriate treatment based on the application. | Extends the service life of the welded component. |

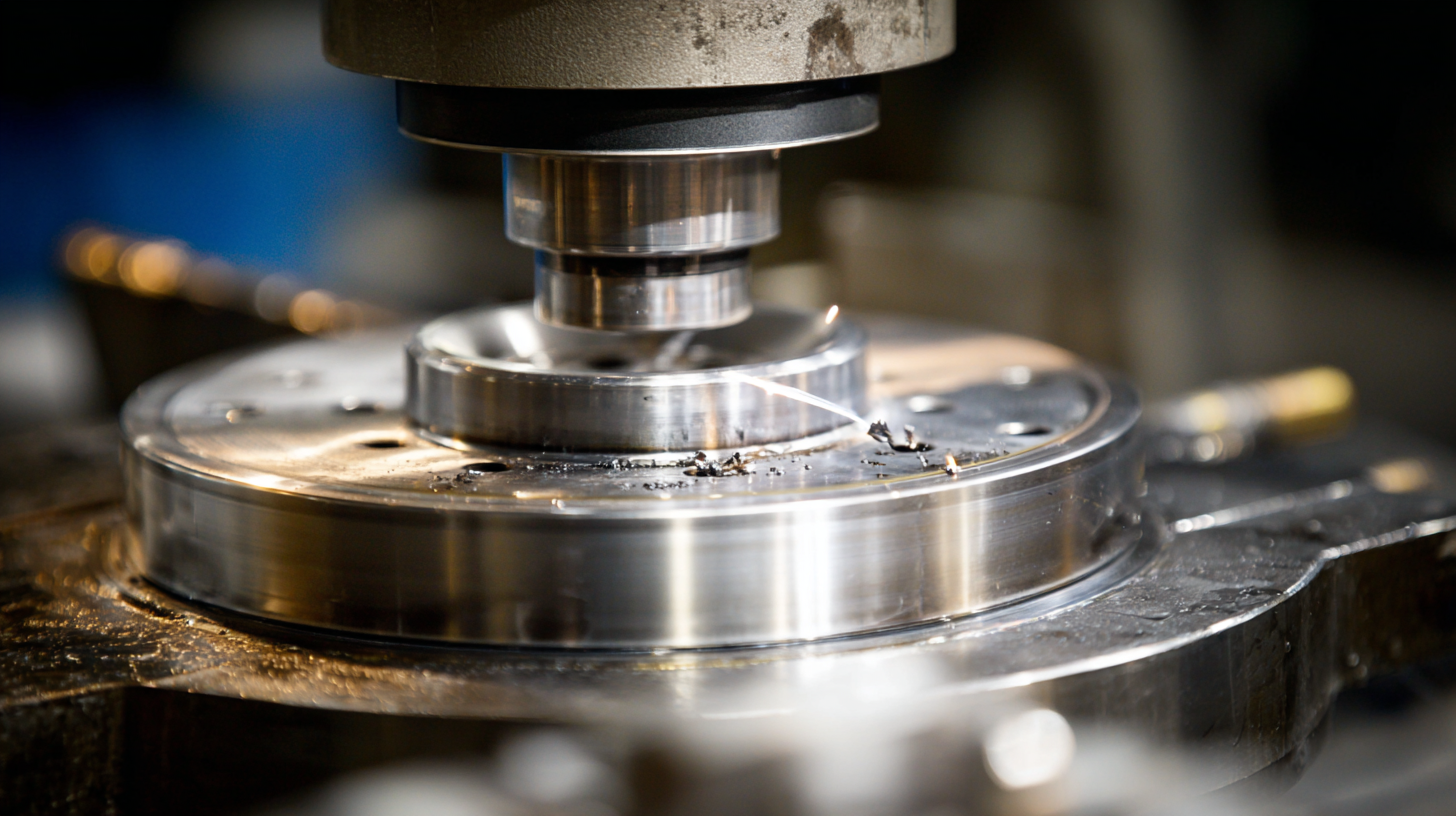

When it comes to mastering stainless steel welding, having the right tools and equipment is essential for achieving high-quality results. According to a report by the American Welding Society, the selection of appropriate welding machines can greatly influence both efficiency and the overall structural integrity of the weld. MIG and TIG welding processes are predominant in stainless steel fabrication, with TIG being preferred for its superior control and precision. In fact, about 45% of fabricators report that TIG welding offers better aesthetics for visible welds, making it crucial for applications in industries such as food processing and pharmaceuticals.

Additionally, the importance of safety gear and consumables cannot be overstated. Protective equipment, including helmets with proper shading, fire-resistant clothing, and gloves, is vital. According to the National Institute for Occupational Safety and Health (NIOSH), the welding industry faces a high risk of injuries, with approximately 15,000 occupational injuries reported each year related to welding activities. To mitigate these risks, investing in quality personal protective equipment (PPE) should be a top priority. Furthermore, using high-grade filler materials and maintaining proper tool maintenance can enhance performance and longevity, ultimately leading to more efficient welding processes and better end products.

Mastering stainless steel welding techniques is fundamental for modern fabrication, given the material's unique properties such as corrosion resistance and strength. A step-by-step approach can demystify the process and enhance skills for both novices and seasoned welders. The American Welding Society (AWS) reports that stainless steel welding accounts for approximately 20% of all welding jobs, emphasizing its significance in various industries including construction, automotive, and aerospace.

First, understanding the different types of stainless steel is essential. Austenitic stainless steels, such as 304 and 316, are commonly used due to their excellent weldability. Techniques like Gas Tungsten Arc Welding (GTAW) and Gas Metal Arc Welding (GMAW) are frequently employed. According to the International Institute of Welding (IIW), GTAW is favored for its precision and control, making it ideal for critical applications, while GMAW is preferred for its efficiency in high-volume production settings.

Next, mastering the proper parameters is crucial. For instance, maintaining the correct arc length and travel speed can significantly impact weld quality. A report by the Welding Research Council highlights that improper settings can lead to defects such as porosity and undercutting, which compromise structural integrity. Therefore, hands-on practice with various techniques in different settings is vital for achieving proficiency in stainless steel welding.

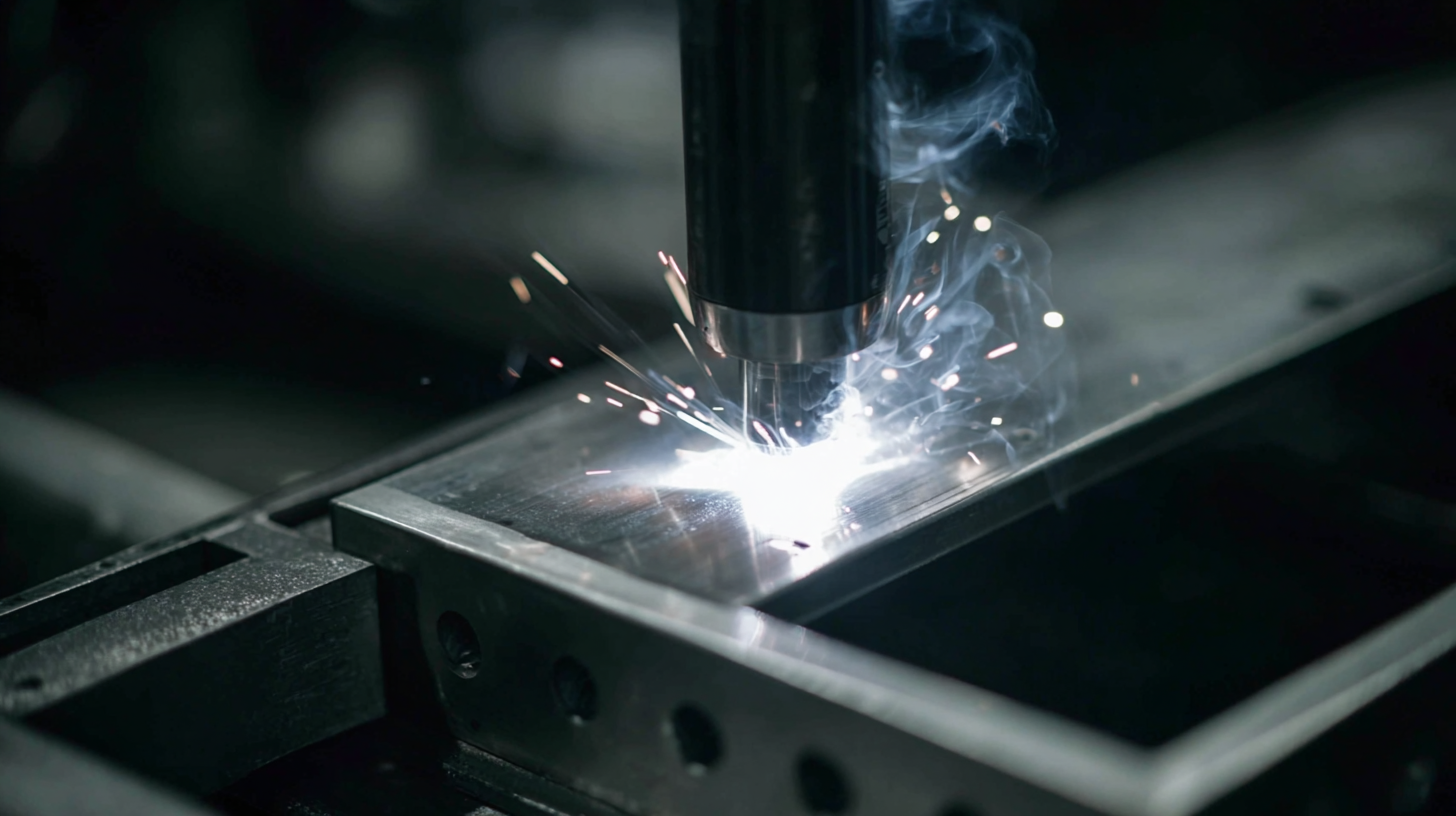

Stainless steel welding can present unique challenges that require specialized techniques and strategies to master. One common issue is dealing with distortion and warping due to the high thermal conductivity of stainless steel. To overcome this, welders can employ techniques such as preheating the material or using a back-step welding pattern to minimize heat concentration. Additionally, understanding the proper filler materials and their characteristics is crucial, as using the wrong type can lead to weak joints and corrosion issues.

Stainless steel welding can present unique challenges that require specialized techniques and strategies to master. One common issue is dealing with distortion and warping due to the high thermal conductivity of stainless steel. To overcome this, welders can employ techniques such as preheating the material or using a back-step welding pattern to minimize heat concentration. Additionally, understanding the proper filler materials and their characteristics is crucial, as using the wrong type can lead to weak joints and corrosion issues.

Another challenge in stainless steel welding is preventing contamination, especially from oils or other foreign substances. Keeping a clean work environment and preparing the metal surfaces properly can reduce the risk of defects. As illustrated by a recent achievement where an expert welded 32 pieces of 0.7mm thick steel into an inflatable iron football, precision and attention to detail are vital. This example highlights how mastering stainless steel welding not only requires skill but also creativity in tackling complex projects, showcasing the endless possibilities in modern fabrication.

Ensuring quality and consistency in stainless steel welds is crucial for achieving durable and visually appealing results in modern fabrication. One of the primary strategies is to maintain a clean working environment. Contaminants such as oil, rust, or dust can significantly impact the quality of the weld. Before starting the welding process, it’s essential to thoroughly clean the stainless steel surfaces using a suitable solvent or abrasive method. This not only prepares the surfaces for better fusion but also helps in preventing defects such as porosity or inconsistent bead appearances.

Another critical aspect is selecting the right filler material and welding technique for the specific type of stainless steel being used. Different grades of stainless steel require different filler metals to ensure strong and stable joints. Additionally, employing methods such as TIG or MIG welding can influence the overall outcome, as these techniques provide varying levels of control over the heat input and bead shape. Consistency in parameters like travel speed, amperage, and shielding gas flow is vital to achieve uniform welds that meet industry standards. By focusing on these essential tips, fabricators can improve the quality and appearance of their stainless steel welds significantly.