In 2023, the landscape of metal fabrication is significantly transformed by the adoption of advanced technologies, particularly the MIG CO2 Welding Machine. As per a recent industry report by MarketsandMarkets, the global welding equipment market is projected to reach USD 22.4 billion by 2025, driven primarily by innovations in welding processes. The MIG CO2 Welding Machine, renowned for its efficiency and versatility, stands at the forefront of this revolution. With its capacity to deliver high-quality welds at accelerated speeds, this technology has become indispensable in sectors ranging from automotive to construction, enabling manufacturers to reduce operational costs while enhancing productivity. Moreover, as industries increasingly prioritize sustainability, the MIG CO2 Welding Machine's ability to minimize waste and energy consumption aligns perfectly with eco-friendly manufacturing practices. This paper delves into how the MIG CO2 Welding Machine not only maximizes efficiency but also propels the metal fabrication industry into a new era of innovation and sustainability.

The evolution of MIG CO2 welding technology in 2023 has marked a significant turning point in the metal fabrication industry. With advancements in equipment and techniques, welders are now able to achieve higher precision and efficiency. This modernized approach not only enhances the quality of welds but also reduces the time needed to complete projects, making it an essential tool for fabricators. Innovations in gas composition and feed systems have further optimized the welding process, allowing for better penetration and less spatter, which translates to cleaner and stronger welds.

Tips for maximizing the effectiveness of your MIG CO2 welding experience include selecting the right wire for your specific application. Using a wire with the appropriate diameter and composition can drastically improve the quality of your welds. Additionally, maintaining a consistent travel speed and angle while welding enables a smoother and more uniform connection. Regular maintenance of your welding equipment, from ensuring the nozzle is clean to checking the gas flow rate, can also prevent issues and keep your welding projects running smoothly.

As the market continues to embrace these technological advancements, the focus will be on integrating automation and digital solutions into traditional welding practices. This shift not only boosts productivity but also improves safety and adaptability in various welding environments, positioning MIG CO2 welding as a cornerstone of modern metal fabrication.

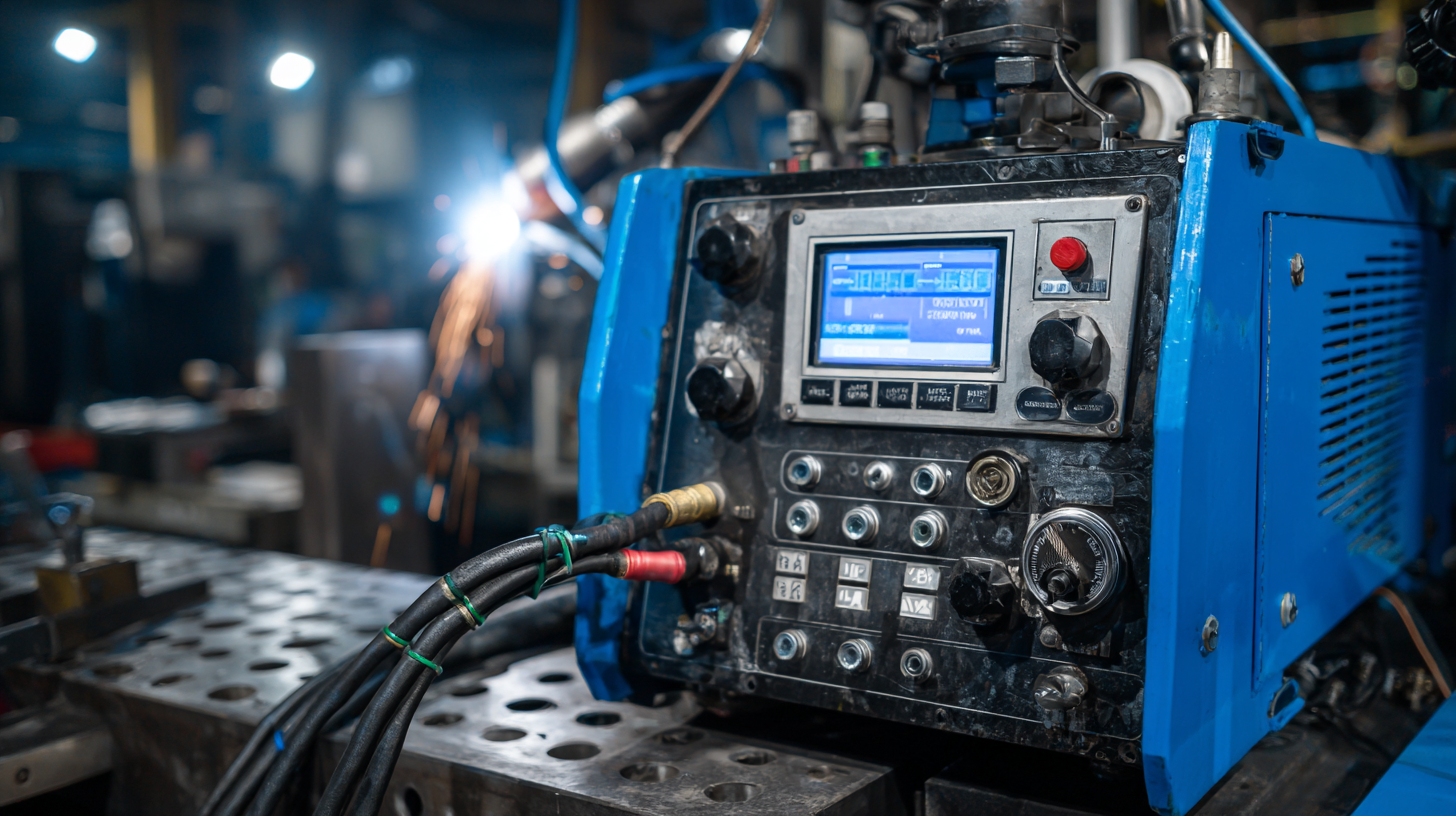

MIG CO2 welding machines have revolutionized metal fabrication in 2023, bringing unparalleled efficiency and versatility to the industry. One of the standout features is their ability to produce high-quality welds with minimal cleanup. The use of CO2 shielding gas not only enhances the welding process but also reduces the overall cost by making the operation more efficient. This feature is particularly beneficial for projects requiring a slick finish without excessive post-weld treatment.

Another notable aspect is the quick setup and ease of use. Many MIG CO2 welding machines come equipped with user-friendly controls that allow even novice welders to quickly learn the ropes. Moreover, the portability of these machines means they can be used effectively in various locations, from workshops to on-site applications. This flexibility empowers fabricators to streamline their workflow and increase productivity.

**Tips:** When using MIG CO2 welding machines, ensure the workspace is well-ventilated to optimize performance and safety. Additionally, regularly check and maintain your welding equipment to prolong its lifespan and maintain weld quality. Finally, consider practicing on scrap metal to improve your skills before starting on the final workpiece.

In 2023, the MIG CO2 welding machine has emerged as a pivotal innovation, transforming metal fabrication through significant efficiency gains. The ability to streamline processes not only reduces operational time but also cuts costs dramatically. According to industry reports, the implementation of MIG welding technology can enhance productivity by 50%, allowing manufacturers to complete projects faster while maintaining high-quality standards. This heightened efficiency is vital in a competitive market, where every second and every dollar counts.

Moreover, advancements in related technologies, such as the evolution of photovoltaic cells—transitioning from P-type to N-type—highlight the broader trend of efficiency optimization in manufacturing. As firms continuously seek to push the boundaries of conversion efficiency and reduce production costs, the integration of innovative machinery like MIG CO2 welders plays a crucial role. Reports indicate that the N-type cells are not only yielding higher efficiency rates but also aligning with the cost-reduction strategies that highlight the industry's forward-thinking approach. The synergy between these technological advancements and welding techniques exemplifies a comprehensive strategy focused on maximizing output and minimizing expenditures in metal fabrication.

This chart illustrates the efficiency gains achieved through the use of MIG CO2 welding machines in metal fabrication in 2023. The metrics captured include time reduction, cost savings, production increase, and waste reduction, showcasing significant improvements in the fabrication process.

The MIG CO2 welding machine has emerged as a game-changer in metal fabrication across various industries in 2023. With its ability to seamlessly weld different materials such as stainless steel, aluminum, and nickel alloys, the MIG CO2 process is becoming increasingly favored in sectors like automotive, construction, and manufacturing. The global welding market, valued at approximately $20.5 billion in 2021, is projected to grow significantly, propelled by advancements in welding technology and increasing applications in industries like energy and marine. As highlighted in recent reports, the demand for solid wire and flux-cored wire in the welding consumables market is intensifying, further exemplifying the relevance of MIG CO2 welding in today’s competitive environment.

The MIG CO2 welding machine has emerged as a game-changer in metal fabrication across various industries in 2023. With its ability to seamlessly weld different materials such as stainless steel, aluminum, and nickel alloys, the MIG CO2 process is becoming increasingly favored in sectors like automotive, construction, and manufacturing. The global welding market, valued at approximately $20.5 billion in 2021, is projected to grow significantly, propelled by advancements in welding technology and increasing applications in industries like energy and marine. As highlighted in recent reports, the demand for solid wire and flux-cored wire in the welding consumables market is intensifying, further exemplifying the relevance of MIG CO2 welding in today’s competitive environment.

Tip: When using a MIG CO2 welding machine, ensure to maintain proper gas flow to enhance arc stability and reduce spatter. Adjusting voltage and wire feed speed can also optimize results for different materials.

Real-world applications of MIG CO2 welding are seen in significant projects, including the construction of offshore oil rigs and renewable energy plants, where precision and efficiency are paramount. The welding consumables market, encompassing stick electrodes and various wire types, is also experiencing shifts due to the COVID-19 pandemic, forcing many manufacturers to rethink their production strategies. According to industry forecasts, the MIG welding segment alone is expected to capture a substantial share of the market, proving indispensable in modern metal fabrication processes.

Tip: Regularly inspect and replace worn welding tips for consistent performance and quality in your welds. Proper maintenance can vastly improve the lifespan of your equipment while ensuring high-quality fabrications.

The landscape of metal fabrication is rapidly evolving, with MIG CO2 welding machines standing at the forefront of innovation in 2023. This technology not only enhances the efficiency of welding processes but also ensures superior quality in finished products. As manufacturers seek to streamline operations and reduce costs, the adoption of MIG CO2 welding presents a compelling solution. Its ability to produce cleaner welds and minimize waste makes it an attractive option for a variety of industries.

Looking ahead, future trends in MIG CO2 welding indicate a significant shift toward automation and integration with smart technologies. As the industry embraces Industry 4.0, the combination of MIG welding machines with advanced data analytics and IoT capabilities will optimize operations, allowing for real-time monitoring and adjustments. This shift not only improves productivity but also paves the way for innovations such as predictive maintenance, reducing downtime and enhancing overall efficiency.

Tips for maximizing the benefits of MIG CO2 welding include regular maintenance of equipment to ensure optimal performance, investing in training for operators to harness the full capabilities of the technology, and exploring automated solutions that can complement manual welding processes. By staying ahead of these trends and implementing smart practices, businesses can thrive in the competitive metal fabrication landscape.