A Mig Welding Machine is a vital tool in metalworking. It uses a continuous wire feed to join materials. This technique is popular for its speed and efficiency. Many industries rely on it for quality welds.

The machine operates by producing an electric arc. This arc melts both the wire and the base material. As the wire feeds into the weld area, it creates a strong bond. Users often appreciate how easy it is to learn. However, mastering the machine takes practice.

Despite its advantages, challenges exist. Understanding settings and equipment can be complex. Users may struggle with inconsistent results if not careful. It's essential to reflect on these aspects to improve skills. Embracing mistakes can lead to better outcomes in the long run.

A MIG welding machine is a versatile tool used in various industries. It stands for Metal Inert Gas welding. This technique is known for its efficiency and effectiveness in joining metals. According to the American Welding Society, MIG welding accounts for approximately 70% of all welding processes in the industry.

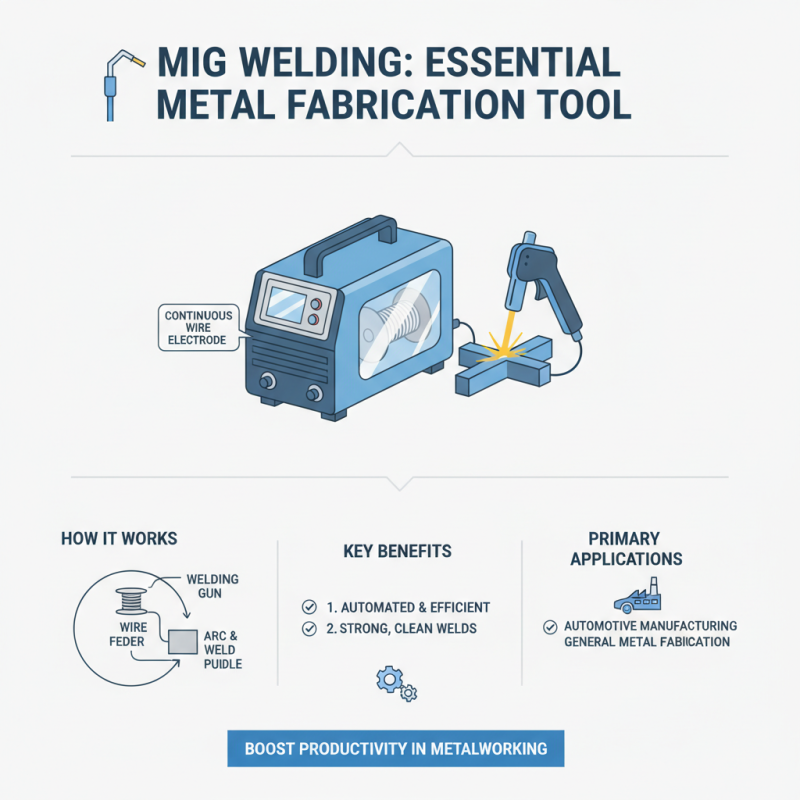

The machine feeds a continuous wire electrode into the weld pool. This wire creates an arc that melts both the wire and the base metal. Inert gases, such as argon or carbon dioxide, shield the weld pool from contamination. This process results in a clean and strong weld. Studies suggest that MIG welding can increase productivity by up to 30% compared to traditional welding methods.

MIG welding is popular due to its ease of use. However, it may not be suitable for all welding projects. For instance, aluminum and stainless steel can pose challenges. Proper settings are crucial for achieving quality welds. A misunderstanding of wire feed speed or voltage can lead to defects. Continuous learning and practice are needed to master this technique. In this way, welding professionals can achieve consistent results and avoid costly mistakes.

A MIG welding machine is an essential tool for metal fabrication. It utilizes a continuous solid wire electrode fed through a welding gun. This automation improves efficiency in various welding applications, particularly in automotive and manufacturing sectors.

Key components include the welding gun, the wire feed system, and the power supply. The welding gun delivers the electrode and shielding gas. It also regulates temperature and provides control over the weld pool. The wire feed system supplies the electrode at a consistent rate, influencing the quality of the weld. Power supply units convert electrical energy, enabling the machine to function properly.

Tip: Regular maintenance of components is crucial. Cleaning the welding gun and ensuring smooth wire feed can significantly enhance performance.

Another key component is the shielding gas, often argon or a mixture of gases. This gas protects the weld from contaminants in the air. Incorrect gas selection can lead to poor weld quality.

Tip: Always check gas levels before starting a project. Low gas can lead to corrosive welds.

While MIG welding offers many advantages, factors like machine setup and technique significantly impact results. Ensuring proper settings is vital for optimal welds.

Mig welding, or Metal Inert Gas welding, is a popular welding method. It uses a continuous wire feeder to create a strong bond between metal pieces. Understanding how it works can make a significant difference in achieving quality welds.

The process begins with the welder setting the parameters, such as voltage and wire feed speed. The welding gun then feeds the wire and supplies shielding gas. This gas protects the molten metal from contamination. The arc forms when the wire touches the workpiece, melting both the wire and the base metal. A puddle of molten metal forms, which cools to create a strong joint. However, it’s crucial to maintain the correct distance between the gun and the workpiece. Too close can cause burn-through, while too far can lead to weak welds.

After welding, inspect your seams closely. It’s easy to overlook imperfections. Look for spatter or incomplete fusion. Each weld is a learning experience. Adjust your technique based on what you observe. Lighting and angle can affect visibility. Practice is key. Don't be discouraged by mistakes; they are often the best teachers.

When using a MIG welding machine, safety is a priority. A machine can create sparks and heat that may cause burns. Always wear protective gear. This includes a welding helmet with appropriate shade. Gloves and flame-resistant clothing are essential. They protect against splatter and intense light.

Ventilation is crucial. Fumes released during welding can be hazardous. Work in an open area or provide enough airflow. Avoid welding in confined spaces. This is where toxic gases can accumulate. Keep a fire extinguisher nearby. Accidents happen, and being prepared helps.

Regularly inspect your equipment as well. Damaged cables or worn parts can lead to failures. Take time to check connections and settings. This simple action can prevent serious injuries. Remember to turn off the machine after use. Ignoring this step can lead to unintentional sparks. A moment of carelessness can have lasting consequences. Stay alert and aware while working.

| Dimension | Description |

|---|---|

| Voltage | Typically ranges from 120V to 240V depending on the machine. |

| Amperage | Commonly varies from 30A to 300A for most MIG welding machines. |

| Wire Diameter | Usually between 0.023 to 0.045 inches depending on the application. |

| Shielding Gas | Often uses a mix of Argon and CO2; ratios vary per requirement. |

| Cooling Method | Air-cooled or water-cooled systems, depending on the application. |

| Weight | Can range from 30 lbs to over 200 lbs depending on the features. |

| Safety Gear Required | Helmet, gloves, welding jacket, and safety glasses to protect from UV light and sparks. |

| Typical Applications | Automotive, construction, maintenance, and manufacturing projects. |

MIG welding, also known as Gas Metal Arc Welding (GMAW), is widely utilized in various industries. Its versatility makes it a go-to method for welding different materials. Common applications include automotive manufacturing, where precision is crucial. MIG welding efficiently joins metal parts, ensuring durability in vehicles.

In construction, MIG welding is essential for fabricating structural components. It allows for quick production times, which is vital on job sites. This method can accommodate different materials and thicknesses, providing flexibility in design. However, achieving clean welds requires skill. Beginners often struggle with settings and technique.

Another area where MIG welding shines is in metal art and sculptures. Artists utilize this technique to create intricate designs. However, the artistic process can be unforgiving. Artists must pay close attention to their settings to avoid flaws in their work. Mistakes can lead to wasted material and effort, prompting a need for constant improvement.