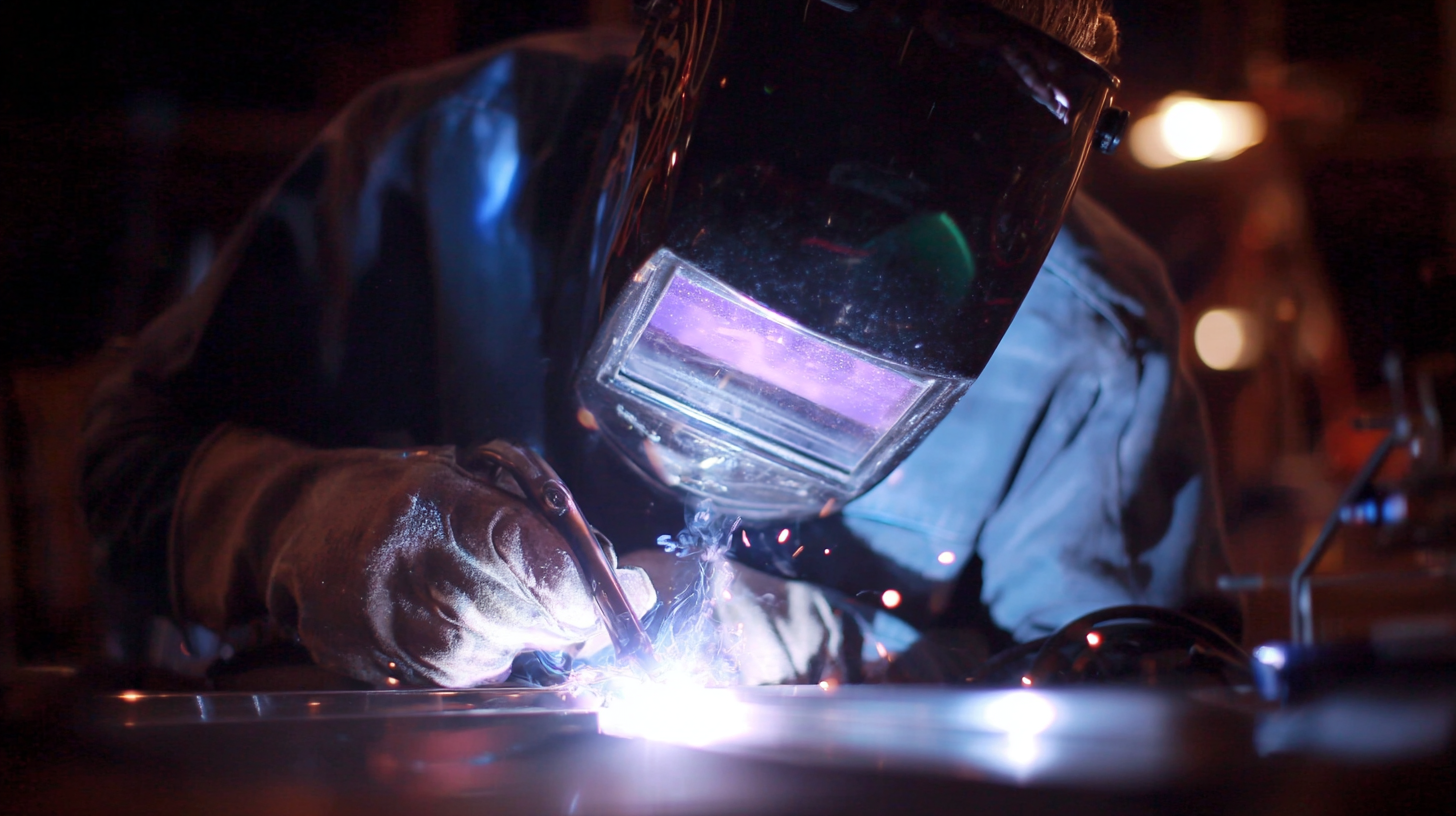

In the ever-evolving world of welding technology, the demand for top-notch equipment has surged, with the global welding market projected to reach a staggering $30 billion by 2025, according to a recent industry report. Among the various welding solutions, the AC DC TIG welder has emerged as a favorite due to its versatility and precision. China's leadership in manufacturing these high-quality machines positions it as a dominant player in global exports. With advanced features that cater to a wide range of applications, from automotive to aerospace industries, the best AC DC TIG welders are essential tools for both professionals and hobbyists alike. As countries like the United States and Germany ramp up their manufacturing capabilities, the need for reliable and efficient welding solutions only grows, highlighting the unmatched quality of Chinese exports in this competitive landscape.

AC DC TIG welding is a versatile and efficient method that stands out in various industrial applications. This welding technique offers precise control over weld quality, making it ideal for thin materials and intricate projects. The dual polarity feature, which allows both AC and DC output, enables welders to tackle a wider range of materials, from aluminum to stainless steel. Understanding these key features enhances the effectiveness of welding operations and ensures optimal results.

AC DC TIG welding is a versatile and efficient method that stands out in various industrial applications. This welding technique offers precise control over weld quality, making it ideal for thin materials and intricate projects. The dual polarity feature, which allows both AC and DC output, enables welders to tackle a wider range of materials, from aluminum to stainless steel. Understanding these key features enhances the effectiveness of welding operations and ensures optimal results.

Tip: When using AC DC TIG welders, it’s essential to set the right balance between cleaning and penetration when welding aluminum. Adjusting the AC frequency can also help control the arc stability, resulting in cleaner welds.

Additionally, the benefits of AC DC TIG welding extend to its ability to produce high-quality, aesthetically pleasing welds. This method minimizes distortion and reduces the need for post-weld cleanup, saving time and resources. It also allows for welds that are strong and reliable, which is crucial in industries where safety and durability are paramount.

Tip: Always ensure proper gas flow and use the right filler material to enhance the quality of your welds. Investing in a quality AC DC TIG welder from a leading exporter can further improve your welding projects, providing unmatched quality and performance.

When selecting the right AC DC TIG welder for your needs, it's essential to consider various factors that can significantly impact performance and efficiency. According to a report by Grand View Research, the global welding equipment market is projected to reach $29.1 billion by 2025, driven by the increasing demand for advanced welding technologies in industries such as automotive and construction. This highlights the necessity for high-quality TIG welders, which combine versatility and precision for a wide range of applications.

One of the key aspects to evaluate when choosing an AC DC TIG welder is the power output. Typically, a welder with a higher amperage range allows for greater control and adaptability for different materials, including aluminum and stainless steel. A study from Markets and Markets indicates that AC DC TIG welders are increasingly preferred for their ability to provide strong, clean welds with minimal spatter compared to traditional welding methods. Additionally, portability features and user-friendly interfaces have become essential attributes for businesses and individual users alike, as they seek efficiency without compromising quality.

| Model | Input Voltage | Welding Current Range (A) | Duty Cycle (%) | Weight (kg) | Price (USD) |

|---|---|---|---|---|---|

| AC/DC TIG Welder Model A | 220V | 10-250 | 60 | 19.5 | 750 |

| AC/DC TIG Welder Model B | 110V/220V | 10-200 | 80 | 14.5 | 600 |

| AC/DC TIG Welder Model C | 220V | 20-300 | 50 | 22.0 | 950 |

| AC/DC TIG Welder Model D | 220V | 5-150 | 40 | 12.0 | 500 |

China has emerged as a powerhouse in the welding equipment industry, particularly in the production of AC DC TIG welders. These machines are renowned for their versatility and precision, making them indispensable for various applications in automotive, aerospace, and construction industries. Leading manufacturers in China have invested heavily in research and development, resulting in advanced welding technologies that not only enhance performance but also improve efficiency and energy consumption.

Among the top manufacturers, companies are renowned for their commitment to quality and innovation. They utilize state-of-the-art manufacturing processes and adhere to international standards, ensuring that their welders meet the needs of both local and global markets. These companies offer a range of products that cater to different welding requirements, allowing customers to choose models equipped with features like high-frequency start, adjustable output, and digital displays. As a result, China's AC DC TIG welders have gained a strong reputation worldwide, providing unmatched quality and reliability for welders at every skill level.

The global market for AC DC TIG welders is evolving rapidly, driven by advances in technology and increasing demand for high-quality welding equipment. A comparative analysis of various models reveals key differences in performance, features, and user experience. For instance, while some welders offer advanced functionalities catering to both amateur and professional welders, others focus on simplicity and ease of use, making them ideal for hobbyists or those new to the craft.

In recent reviews, specific machines have stood out due to their superior precision and robust power delivery. It is essential for welders to consider these aspects when selecting equipment, as the right welder can significantly impact the quality of the finished work. Additionally, market forecasts indicate that the demand for well-engineered welding solutions will continue to rise, highlighting the importance of manufacturers who prioritize unmatched quality and innovative design in their offerings. As the welding equipment landscape evolves, staying informed about the latest technologies and trends will be crucial for those seeking to invest in the best tools available.

Maintaining your AC DC TIG welder is crucial for ensuring optimal performance and longevity. Regular cleaning of the machine is a fundamental step that cannot be overlooked. Dust and debris can accumulate in the interior and around the connectors, which may lead to overheating or performance issues. After each welding session, take the time to blow out any dirt using compressed air and wipe down external surfaces with a cloth. This simple practice can significantly extend the life of your welder.

Another important aspect of maintenance is checking the consumables, such as tungsten electrodes and filler rods. Over time, these components can wear down and impact the quality of your welds. Regularly inspect the tips of your tungsten electrodes for signs of contamination or wear, and replace them as needed to maintain a clean arc. Additionally, ensuring that your gas flow is set correctly will help prevent oxidation and improve the overall quality of your welding results. Staying proactive with these maintenance tasks will keep your AC DC TIG welder functioning at its best.