The world welding technology is advancing at lightning speed; precision and efficiency have become a concern for industries all over. Demands for excellent quality in welding solutions are reported by various market research; from this research, it can be understood that the global welding equipment market will reach USD 25 billion by 2025, primarily fueled by the construction and automotive industry. When it comes to welding processes, Tungsten Inert Gas (TIG) welding has gained popularity due to its ability to produce clean and precise welds. In the process of making high-standard quality welds, the Tig Machine is considered the foremost tool, giving welders the necessary control and versatility to complete intricate tasks with ease.

At TAIZHOU YIKE MACHINERY CO., LTD, we stand behind the phrase that any professional should work with only the best tools. Our company is situated at Xiayangzhang Daxi Town Wenling City, Zhejiang, China, and specializes in manufacturing diverse inverter welding machines, including the Tiger Machine. Our commitment to high quality with less cost makes us the ideal sourcing partner for you in the welding industry. Close to Taizhou Airport for transport, and Ningbo & Shanghai ports, we are well-poised to serve domestic and international customers, year-round with precision welding in reach at all times.

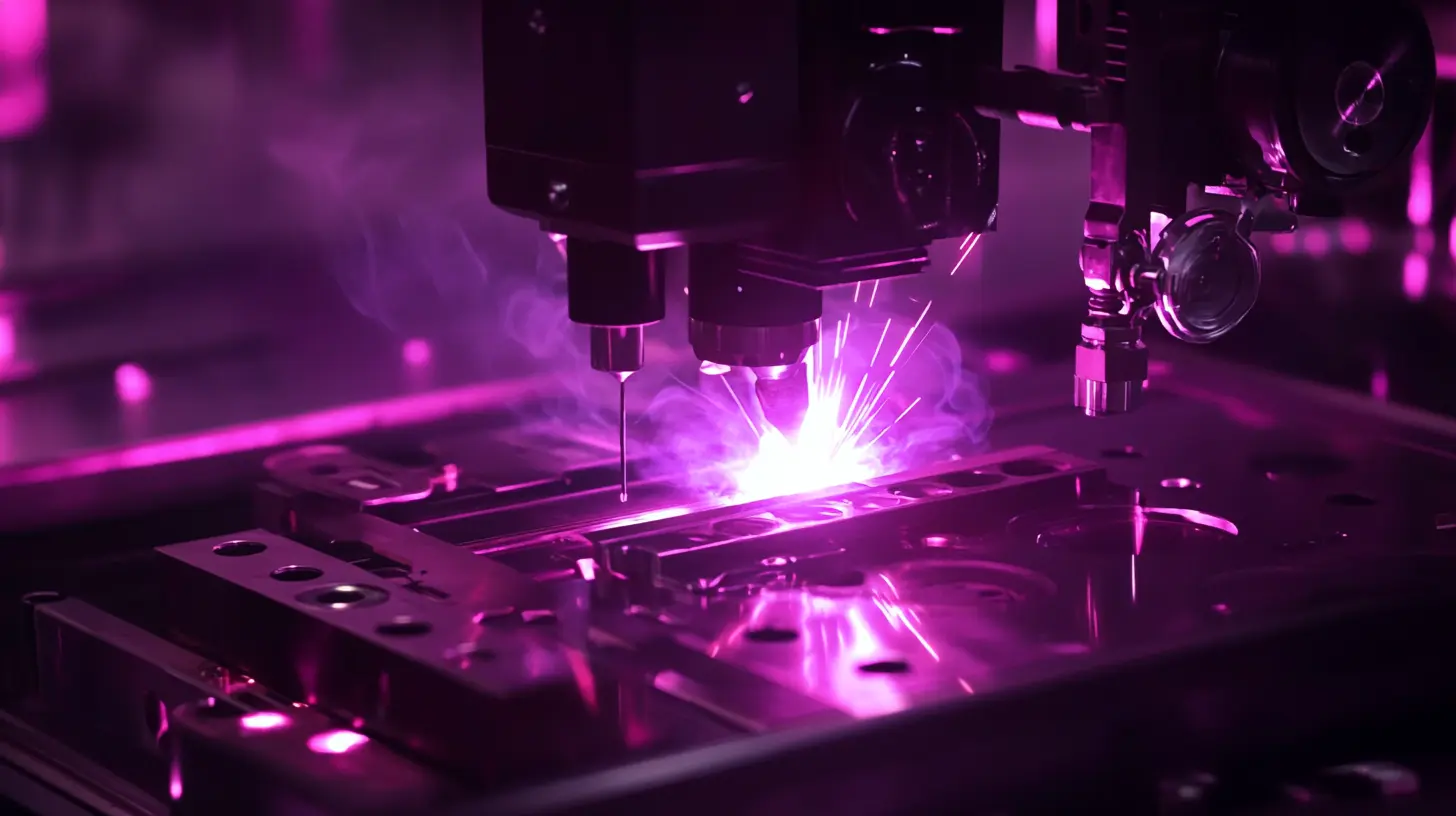

Welding using TIG (tungsten inert gas) has now really been a big changer in the field of precision welding, as far as the fabricators view their projects. The major scream among welding technologies, TIG welding is the highest point used by an operator to produce a very clean, strong, and aesthetic weld. Unlike most welding processes, these welds are achieved using a non-consumable tungsten electrode and a shielding gas that protects the area of welding from contaminants. This makes TIG welding so beneficial even for applications where very accurate detailing is required such as aerospace, automotive, and artistic metalworks. This TIG revolution is completely different from all the other tools for revolutionizing welding technology. Digital control panels, programmable settings, and superior thermal management are just some of the blasted features used in these welders to help welders achieve consistency in results despite using different materials and thicknesses. In addition to being extremely skillful, modern TIG machines have been designed to function user-friendly interfaces to ensure ease of learning for both the novice and seasoned professionals, thereby great results. Thus, rather than being the preserve of the few, precision welding will, in turn, become open to a wider audience, hence innovative and top-quality welding in sectors. Beyond that, narrative these advanced TIG machines are changing the very paradigm of sourcing solutions for welding types on the market. The integration of machine-high quality in manufacturing lines is increasingly being acknowledged by the manufacturing companies in this buying of high-tech TIG. By advancing in sourcing advanced TIG machines, industries can cope with the ever-increasing demand for precision welding, thereby recording improvement in productivity and cost savings through reduced operation. As the different sectors continue to evolve themselves, it becomes highly likely that companies that go in for state-of-the-art TIG technology are still going to be competitors ahead of others, setting standards in precision and quality in the future.

The development of revolutionary TIG - Tungsten Inert Gas - apparatus has transformed precision welding. Among the characteristics that distinguish these machines from conventional machines is their ability to generate very superior arc stability. Thus innovation minimizes spatter, provides much cleaner welds, and improves significantly the final work of the product. With modern inverter technology, advanced sophisticated TIG machines provide better control over welding parameters which allows the changes to be made easily as per requirements to fit different materials and thicknesses.

One of the great extras is the introduction of digital displays and sophisticated user interfaces. It offers welders the possibility of real-time parameter feedback and settings to make the work very much more intuitive. In addition to that, users can also track their voltage and amperage so that they know the changes and can make quick alterations to attain the best welding action. Such control minimizes defects and guarantees consistency in as many welding jobs as are done, whether by a beginner or well-trained person.

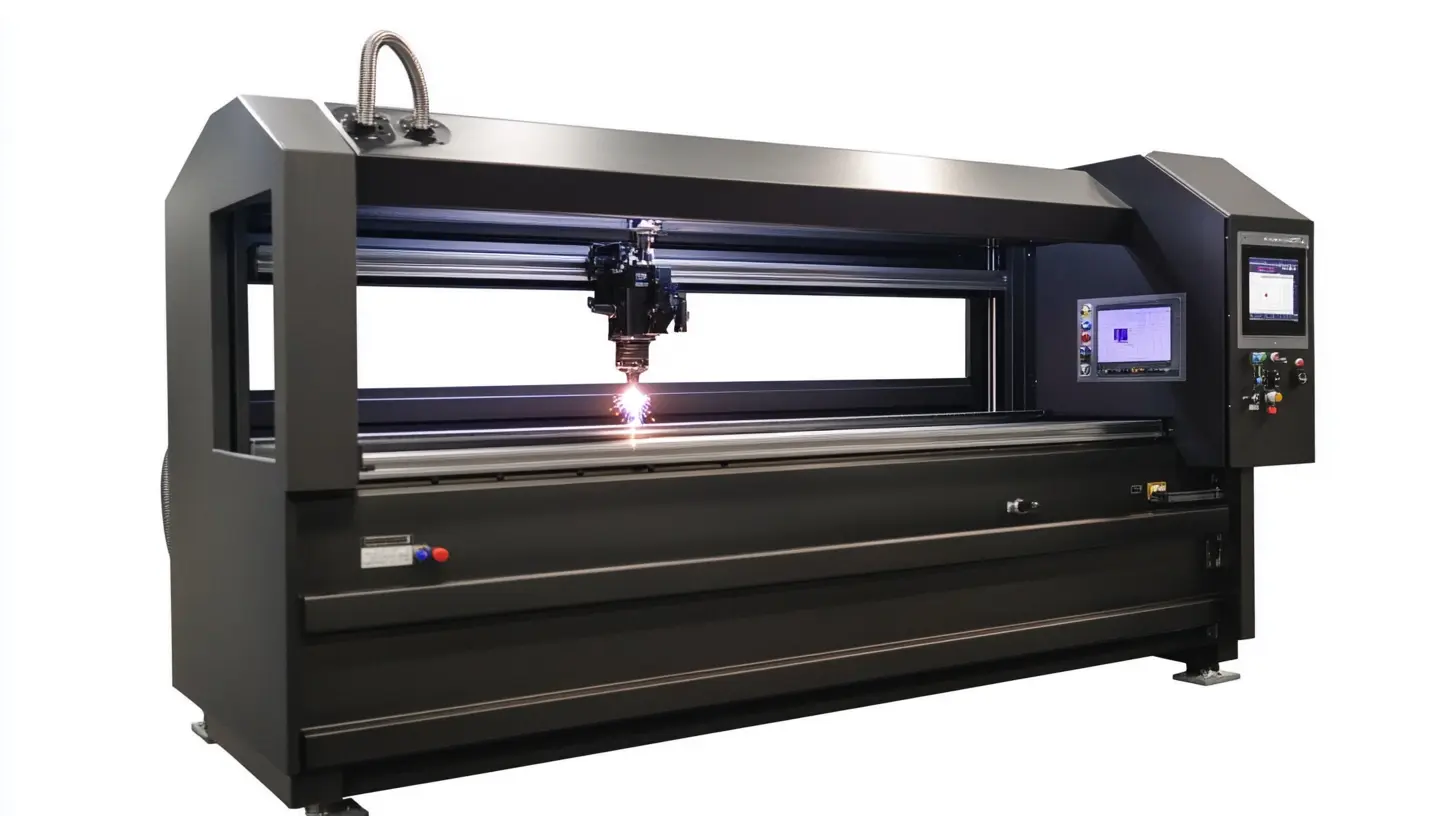

Some revolutionary TIG machines are designed particularly for portability. It is lightweight, sturdy, and easy to transport from one job site to another. Hence, it can be employed for both industrial uses and small workshops. The compact design did not sacrifice performance; it instead represents an excellent combination of efficiency and convenience. As industries demand higher quality welding, rapidly increasing modern TIG machine features are keeping pace with high-quality standards and turning into essential tools ready to face the tough welding precision.

As a process featuring adaptability and precision, TIG (Tungsten Inert Gas) welding is growing in popularity amongst industrial welders as a method for fabrication enriching modern manufacturing. As this demand for better and more consistent welding routines rises in nuclear power production and aerospace, creating clean, strong welds befits many other materials too; hence, it is rapid to be placed on the list of frontrunners by laying itself down as an ideal weld facility. Recent development in TIG technology: the introduction of state-of-the-art TIG machines adds to exactly this great welding process, thus permitting even better control and efficiency in the production line.

This achievement represents an indication of what TIG welding can do with the challenge of demanding and industrial applications; for example, it has completed the main pipeline welding for Hainan Changjiang Nuclear Power Unit 4. Such achievements indicate how possible such welding is in the current alignment of industry trends toward increasingly safety and qualified measures. Furthermore, newly emerging lightweight bicycles, which were recently showcased at the Philly Bike Expo events, have underscored the great weld technologies of which include TIG as major factors in manufacturing processes that blend great performance with inspirational design. As the practice of adopting such technologies continues across various manufacturing sectors, TIG will be in an even stronger position to lead modern fabrication techniques.

Advanced technological progress limits of inter TIG welding technology in weld cost reductions are a transition exercise for welding, as the market grows from $23.75 billion in 2022 to $34.18 billion by 2030. Efficiency and precision have thus become critical in the overall pose of the growth of the welding industry. Versatile operation and good-quality welds are TIG machines' two salient advantages in significantly reducing the costs of rework and material wastage.

Latest advances in welding technology boost the cost efficiency aspect of welding. By automating some processes and better controlling the shielding gas flow, companies will optimize their welding systems, leading to lower operational costs and faster time to project completion. In this respect, manufacturing companies utilizing modern TIG technologies are reducing their labor and material costs, thus allowing for cross-allocation of resources to other projects.

Furthermore, the interoperability of TIG machines with varied industrial applications ranging from construction to precision manufacture represents impeccable functionality and workflow streamlining, all while honoring the highest quality standard. Such efficiencies compel organizations to evaluate sourcing options in line with their operational goals, resulting in outstanding savings and enhanced bottom lines. With increasing technology evolution, firms investing in the latest TIG machines will have a greater business advantage over their competitors in the market.

Technology is on an ever-increasing path to facilitating productivity like never before in every imaginable sector, and an advanced breed of TIG machine technology is an excellent example. Inasmuch as organizations are finding means to maketechnological increasing productivity in their operations, the enhancement offered by a handful of advanced TIG machines will have opportunities that will be crucial. In one of the recent advancements, these machines ensure enhanced precision with welding applications but also further enhance considerable productivity. In a report by Google, AI is said to provide an astonishing 122 hours a year in productivity for each and every employee in the organization, announcing yet another trend regarding technology serving as a force multiplier in workplaces.

With respect to the welding industry, revolutionary TIG machine technologies have reduced lead times and production wastages. Automated processes and advanced control systems provide companies with the capability to produce excellent, high-qualify welds with reduced material usage. The welding industry is, therefore, an example of how technology creates a new kind of interplay between detection and productivity, as it balances between the demand side and supply side, which tends towards the ideals of sustainable development propagated by new productivity types championed by the Chinese government.

Additionally, just as the Canadian e-commerce platform Shopify is encouraging businesses to utilize artificial intelligence (AI) tools for improved team efficiencies, the welding sector must keep in step. Data shows that as skilled laborers are retrofitted with the skills to operate advanced machines, they enrich the general skill set, which translates to better product outcomes. The transition to higher quality production capabilities brings into focus a critically relevant issue of moving production not just into newer realms of productivity but raising the quality of those developments.

As with any demanding task, there are many personalities that must be arranged to complete the perfect task, but there are some that get defined as literal 'characters' as many have attributed the maintenance of the 'fine line' job to the manual skill of the welding artisan. So if one ever comes to cut down a heavier material welding torch in charge, it is tasked with the perfect execution of the character role: accuracy, movement, positioning, aesthetics- any requirement for becoming the soaring glory or downright shame of a work welding signature. In later studies, it has been shown that a welding technology that operates on the circuit of melting base metals, which uses a tungsten electrode to generate an arc and can produce welds of extremely high standards, offers unprecedented control over the meantime-welding process with the lowest defects possible. In recent TIG welding analysis, it was portrayed as the most convenient and the most favourite process, due to the role that highly skilled workers yield in poring necessity to accuracy in welding affairs. Amongst many others, quite evidently, a recent analysis had elevated the commanding satisfaction of TIG welders in respect to monetary valuation.

The beauty is that deep penetration TIG welding not only improves damage tolerance in concrete structures but also encourages the application of advanced materials such as titanium alloys. Industry leaders have shown that adopting precision welding technology significantly raises the bar for the quality of manufacturing and efficiency as well as the aesthetic requirements for weld appearance.

Modern TIG welding equipment is not merely the adoption of advanced technology but a considerable step toward elevating workplace safety. Employee protection takes a higher priority in industries today, given the growing place of these machines. The American Welding Society (AWS) has reported that injuries in the workplace related to metal fabrication have dropped remarkably due to advances in welding technology, one of which is the safety components installed in modern TIG machines.

Indeed, contemporary machines are not only seen to have ventilation facilities, enhanced safety features when dealing with live electricity, and ergonomics that do reduce physical strain on operators, but all of these are leading up to a much safer and more efficient working environment.

Modern machines are really another major aspect of their role in current practice with reference to sustainable development. The latest models offer Bosch energy efficiency when the world's manufacturers attempt to convert their potential energy savings not only into reduced operational costs but also into environmental conservation efforts. As indicated in a report from the International Energy Agency (IEA), energy efficiency technology for manufacturing would save globally up to 25% in energy consumption by 2030. With industries now switching over to a more eco-friendly technique in their processes, modern TIG machines are at the forefront in bridging the gap between productivity and environmental stewardship.

Today, it is pertinent and vital that safety increases in the workplace go hand in hand with eco-conscientious practices at this stage in manufacturing. The innovations made in TIG technology are showing advanced progress, promising enormous solutions that not only serve immediate concerns on safety and efficiency but also contribute to the environment as a whole. As industries continue to evolve, emphasizing worker protection will proceed together with ecological responsibility in reshaping the future of welding practices.

Continuous improvement is on-going with TIG welding technology because of improvements that will enhance precision and efficiency in manufacturing. Today, the focus of these advancements is on the unification of automated and intelligent solutions in smarter TIG welding machines. Indeed, those innovations present themselves with real-time monitoring and adaptive control, while simplifying and streamlining high-quality production through modernized interfaces.

AI in TIG welding forms a core component to manufacture smarter surroundings as businesses are transforming and innovating. Predictive maintenance minimizes idle time while optimizing production times. Meanwhile, increased attention to sustainability is requiring manufacturers to further develop environmentally friendly welding processes and materials, further bolstering the industry's commitment to reducing carbon footprints and improving operations.

The future of TIG welding is pointing to a very exciting horizon with precision technology continually on the move. What these companies are doing is to build a new and high-quality manufacturing system, which will not only enhance their competitiveness but also redefine the potential applications of welding across several industries. This revolution is very much part of a wider trend in the global marketplace where the engine of innovation leads the way for growth and adaptation.

TIG (Tungsten Inert Gas) welding is a process that offers unparalleled control, producing clean, strong, and aesthetically pleasing welds. It is particularly advantageous for applications requiring meticulous attention to detail, giving it a transformative role in precision welding.

Modern TIG machines include advanced features such as digital control panels, programmable settings, superior thermal management, and user-friendly interfaces that make it easier for both beginners and experienced welders to achieve exceptional results.

By integrating high-quality TIG machines, manufacturers can meet the rising demand for precision welding, leading to enhanced productivity and reduced operational costs, thus staying ahead in the competitive landscape.

Modern TIG machines include improved ventilation systems, electrical safety measures, and ergonomic designs that minimize physical strain on operators, significantly reducing workplace injuries in metal fabrication.

Updated TIG machines offer energy-efficient operations that reduce operational costs and contribute to environmental protection efforts. This aligns with the trend towards more eco-friendly practices in manufacturing.

As industries prioritize worker safety, modern TIG welding technology plays a crucial role in creating safer and more efficient working environments, which is increasingly recognized as an important factor in manufacturing practices.

Yes, modern TIG machines are designed with intuitive interfaces that make precision welding attainable for novices, allowing them to produce high-quality welds with proper training.

TIG welding offers greater control and quality in welds compared to traditional methods, making it more suitable for high-precision applications in industries like aerospace, automotive, and artistic metalwork.

Industries such as aerospace, automotive, and artistic metalwork particularly benefit from TIG machines due to the method's ability to produce high-quality, detailed welds.

Companies adopting cutting-edge TIG technology are likely to set new standards in precision and quality, influencing industry practices and expectations positively.