In the realm of metal fabrication, Smaw Arc Welding stands out as a pivotal technique that drives efficiency and quality. With the global market for metal fabrication projected to reach $7.88 trillion by 2025, the demand for reliable welding methods is more pressing than ever. According to a 2021 report by IBISWorld, the welding services industry in the U.S. alone generates approximately $18 billion in revenue, highlighting the significance of advanced welding techniques like Smaw. This process, characterized by its versatility and adaptability to various environments, allows fabricators to achieve strong welds on different metal types, making it essential for construction, manufacturing, and repair sectors. As industries strive for greater productivity and reduced operational costs, understanding the intricacies of Smaw Arc Welding becomes crucial for optimizing performance and maintaining competitive edge.

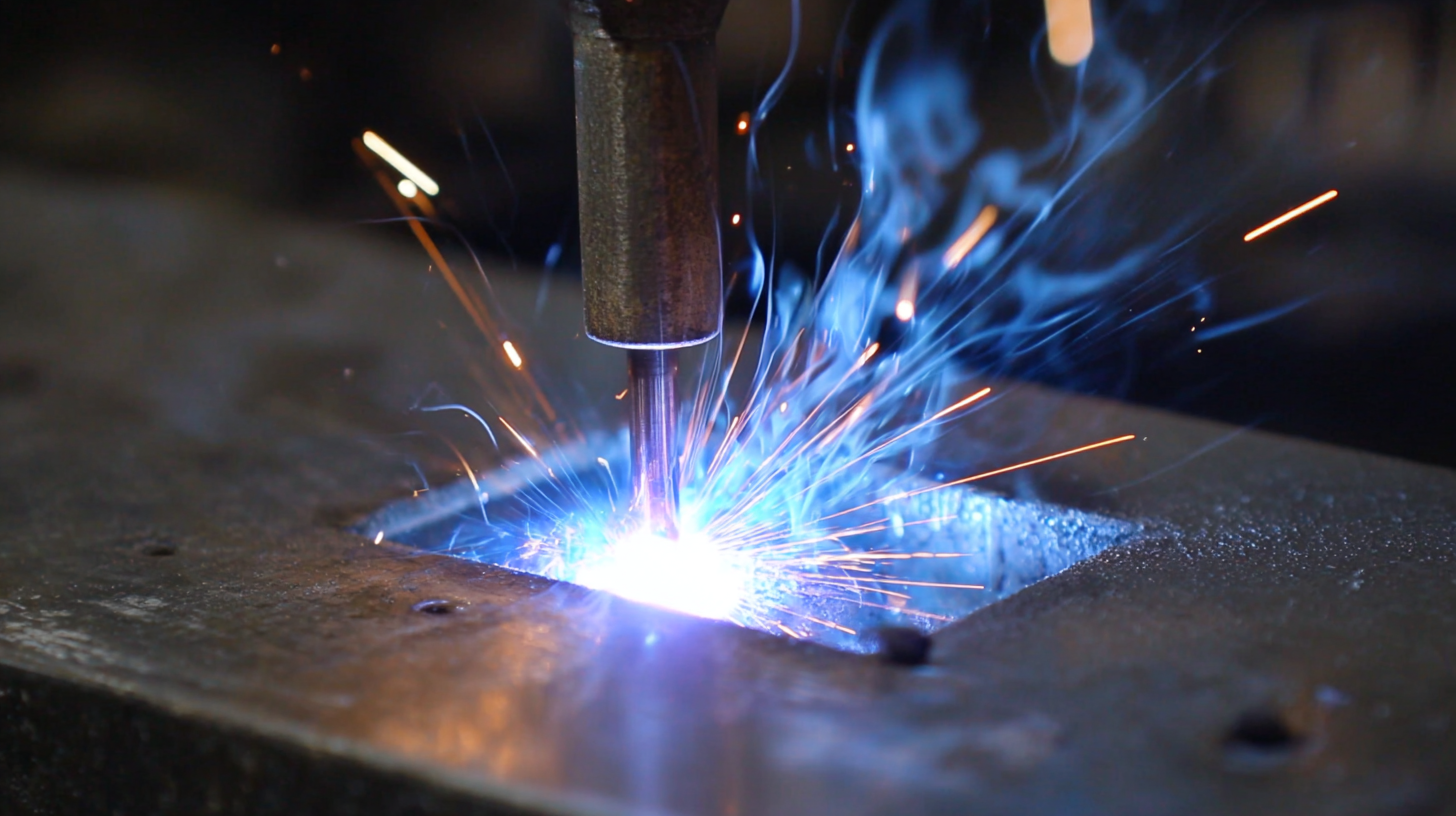

Shielded Metal Arc Welding (SMAW), commonly known as stick welding, is an essential technique in metal fabrication. For beginners, understanding the fundamentals of SMAW is crucial to mastering this skill. This process involves an electric arc formed between a covered electrode and the base metal, melting the electrode's coating and the base material simultaneously.

The composition of the electrode's flux helps to protect the molten weld pool from atmospheric contamination, stabilizing the arc and producing a strong bond between metal pieces.

Beginners should first familiarize themselves with equipment such as the welding machine, electrodes, and safety gear. Proper setup and maintenance of the welding machine ensure consistent performance. Additionally, learning welding techniques, such as control of the welding speed and angle, can greatly enhance the quality of the welds produced.

Practicing on scrap metal allows newcomers to refine their skills before attempting more complex fabrication tasks. Through dedication and practice, mastering SMAW can significantly improve efficiency in metalworking projects.

SMAW, or Shielded Metal Arc Welding, is crucial for efficient metal fabrication, but its success heavily relies on the right equipment and materials. The primary components needed include a power source, welding electrode, workpiece, and suitable protective gear. A reliable power source can be either AC or DC, and choosing the correct type based on the project requirements is essential for achieving a strong weld. Moreover, various electrodes catering to different metals and thicknesses help in ensuring optimal results.

Tips: When selecting electrodes, consider their compatibility with the workpiece material. For instance, using a low hydrogen electrode is advisable for carbon steel to minimize the risk of cracking. Additionally, maintain a clean work environment to remove any contaminants from the welding area, as this will significantly enhance the quality of the weld and prolong the life of your equipment.

In addition to the core equipment, proper safety gear—like helmets, gloves, and protective clothing—is mandatory to ensure welders are shielded from harmful UV rays and sparks. Investing in high-quality safety equipment not only protects the welder but also promotes a culture of safety in the workplace. Regular inspections of your equipment and gear will also enhance performance and maintain safety standards.

| Equipment/Material | Description | Importance |

|---|---|---|

| SMAW Machine | A power source that generates the electric arc for welding. | Essential for initiating the welding process. |

| Electrodes | Metal rods coated with flux used during welding. | Provide filler material and protect the weld pool. |

| Protective Gear | Includes gloves, mask, and aprons to protect the welder. | Ensure safety from sparks, UV radiation, and heat. |

| Welding Rod Holders | Devices to hold the electrodes during welding. | Facilitate better control of the welding process. |

| Ground Clamp | Attaches the workpiece to the electric ground. | Ensures a complete circuit for the welding arc. |

| Welding Blanket | Flame-resistant material to protect surrounding areas. | Prevents fires during the welding process. |

Shielded Metal Arc Welding (SMAW) is a versatile and widely used technique in metal fabrication, offering a myriad of applications across various industries. To master SMAW techniques, it's essential to follow a structured approach. Start by understanding the fundamentals of the process—SMAW involves using a consumable electrode coated in flux to create an arc between the electrode and the workpiece. This process not only allows for high-quality welds but also provides versatility in welding different materials, including carbon steel, stainless steel, and even cast iron.

Next, familiarize yourself with essential equipment and safety protocols. According to the American Welding Society, proper training in welding techniques and safety measures can reduce workplace accidents by up to 30%. Begin with practice exercises that focus on electrode angles, travel speeds, and arc length. Gradually progress to joining thicker materials, applying different joint configurations, and understanding welding positions. Engaging with these techniques not only enhances skills but can also significantly improve production efficiency, contributing to a more effective and profitable metal fabrication operation. By emphasizing hands-on practice and continuous learning, fabricators can harness the full potential of SMAW in their projects, leading to superior quality and performance in their welding tasks.

SMAW (Shielded Metal Arc Welding) is a widely utilized welding process that offers significant advantages in metal fabrication, but it also presents several challenges that practitioners must address to enhance efficiency. One common issue is voltage fluctuation, which can lead to inconsistent weld quality. According to the American Welding Society, improper voltage settings can reduce weld penetration and result in increased defects, impacting overall productivity. To mitigate this problem, welders should regularly calibrate their equipment and ensure proper maintenance to maintain consistent voltage levels.

SMAW (Shielded Metal Arc Welding) is a widely utilized welding process that offers significant advantages in metal fabrication, but it also presents several challenges that practitioners must address to enhance efficiency. One common issue is voltage fluctuation, which can lead to inconsistent weld quality. According to the American Welding Society, improper voltage settings can reduce weld penetration and result in increased defects, impacting overall productivity. To mitigate this problem, welders should regularly calibrate their equipment and ensure proper maintenance to maintain consistent voltage levels.

Another challenge in SMAW is the formation of slag, which can obscure the weld pool and hinder visibility. As reported by the Welding Journal, excessive slag can increase the time spent on cleaning between passes, leading to inefficiencies. To overcome this, welders should select the appropriate electrode type for the material being welded and develop a systematic cleaning routine to minimize slag buildup and maximize efficiency.

Tips:

- Always ensure that your welding equipment is well-maintained and calibrated to achieve stable arc conditions.

- Consider using low-slag electrodes to improve visibility and reduce post-weld cleanup time. Regular training on best practices can significantly enhance overall productivity in SMAW processes.

To maximize efficiency in metal fabrication using Shielded Metal Arc Welding (SMAW), it is essential to invest in proper training for operators. Skilled welders who understand the nuances of SMAW can significantly reduce downtime and improve weld quality. Training programs should cover essential techniques, safety measures, and troubleshooting methods, ensuring that operators are well-equipped to handle various welding challenges.

Additionally, maintaining a well-organized workspace is crucial for enhancing productivity. Keeping tools and materials easily accessible minimizes time spent searching for equipment, allowing welders to focus on their tasks. Implementing a systematic approach to material handling, like using carts or organizing items by frequency of use, can streamline operations and lead to faster turnaround times in production. Moreover, regular maintenance of welding equipment is vital to avoid malfunctions and extend the lifespan of tools, ensuring that operations run smoothly and efficiently.