As industries evolve, trade fairs serve as a vital platform for showcasing innovations and understanding emerging trends. The 138th Canton Fair in 2025 is poised to highlight the impact of cutting-edge technologies, particularly the advancements brought by Tig Machine in the manufacturing sector.

According to a recent industry report by MarketsandMarkets, the global welding equipment market is anticipated to reach $27.2 billion by 2025, illustrating a compound annual growth rate (CAGR) of 3.5%. This growth reflects a substantial demand for high-performance machines, where Tig Machine stands out by offering enhanced efficiency and precision.

With the increasing emphasis on automation and quality in manufacturing processes, Tig Machine’s presence at the Canton Fair will undoubtedly shed light on revolutionary techniques and set new benchmarks for industry standards.

As such, this event will become a critical touchpoint for stakeholders looking to navigate the future landscape of manufacturing technology.

With the increasing emphasis on automation and quality in manufacturing processes, Tig Machine’s presence at the Canton Fair will undoubtedly shed light on revolutionary techniques and set new benchmarks for industry standards.

As such, this event will become a critical touchpoint for stakeholders looking to navigate the future landscape of manufacturing technology.

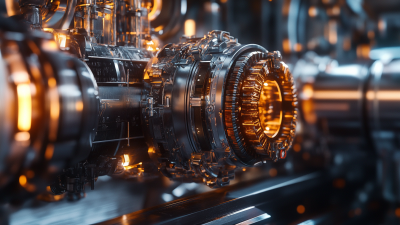

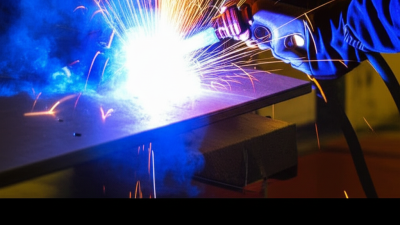

At the 138th Canton Fair, Tig Machine showcased its groundbreaking technologies that are set to revolutionize the manufacturing landscape. With a focus on automation and precision, the company presented advanced welding equipment designed to enhance productivity while maintaining the highest standards of quality. The innovations include state-of-the-art TIG (Tungsten Inert Gas) welding machines that integrate smart technology, allowing for real-time adjustments and monitoring, making the welding process not only more efficient but also safer.

Additionally, Tig Machine's commitment to sustainability was evident in their product offerings. The company introduced eco-friendly welding solutions that minimize waste and energy consumption. By utilizing advanced materials and manufacturing techniques, their machines are optimized for less environmental impact while delivering top-notch performance. The positive reception at the fair indicates a growing industry trend towards embracing sustainable practices and innovative technologies, aligning with the global push for more responsible manufacturing methods.

The 138th Canton Fair in 2025 will serve as a pivotal platform to analyze market trends in the welding industry, particularly reflecting the impact of advanced technologies like TIG machines. As the demand for high-quality welding solutions surges, with the global welding equipment market projected to reach $XX billion by 2026, manufacturers and buyers alike are keenly observing technological innovations that enhance welding precision and efficiency. The implementation of TIG machines, recognized for their versatility in various applications, is anticipated to play a crucial role in shaping the competitive landscape at this premier trade fair.

Tips: To gain the most from your visit to the Canton Fair, consider setting clear objectives and researching exhibitors prior to the event. It’s also beneficial to network with industry professionals to identify emerging trends and best practices in welding technology.

Furthermore, the integration of automation and robotics within the welding sector, as highlighted in recent industry analyses, indicates a shift towards enhanced productivity and innovation. This trend is expected to be a focal point of discussion at the fair, as companies showcase their latest advancements in automation technology. Attendees will have the opportunity to explore solutions that not only improve manufacturing efficiency but also address the growing importance of sustainability within the industry.

At the 138th Canton Fair 2025, industry leaders discussed the transformative role of Tig Machine in shaping the future of manufacturing and technology. With advancements in Industry 4.0, Tig Machine's integration of digital technologies has become a cornerstone in enhancing efficiency and sustainability. By leveraging innovations such as AI and machine learning, the company is not only streamlining operations but also addressing the growing demand for renewable energy solutions. This shift is essential for companies looking to stay competitive in a rapidly evolving market.

The insights shared by industry experts highlighted that Tig Machine's efforts are pivotal in the ongoing convergence of IT and operational technology (OT). This convergence is crucial for optimizing business operations and scaling capabilities in manufacturing processes. As companies navigate the complexities of integrating advanced technologies, Tig Machine stands out as a key player, enabling organizations to harness the potential of AI and automation for improved productivity and cost-effectiveness.

At the 138th Canton Fair in 2025, Tig Machine showcased its innovative technologies and robust product line, standing out among competitors in the welding machinery sector. The fair provided a unique platform for industry players to demonstrate their latest advancements, and Tig Machine's focus on high-efficiency and eco-friendly solutions attracted significant attention. This comparative analysis examines how Tig Machine’s offerings not only meet but exceed the expectations set by competing brands.

While competitors focused on traditional designs and incremental improvements, Tig Machine differentiated itself through its commitment to cutting-edge technology and sustainability. Their range of TIG welding machines features enhanced energy-saving functions and user-friendly interfaces, making them appealing to both seasoned professionals and newcomers. In contrast, competitors displayed models that, while functional, lacked the innovative flair that Tig Machine brought to the exhibition. This commitment to innovation not only positions Tig Machine as a leader in the market but also sets a benchmark for quality and performance that rivals will need to meet in the coming years.

The global trade dynamics are experiencing significant shifts as technological advancements and geopolitical tensions redefine market landscapes. At the forefront of this transformation is the anticipated growth of the construction equipment sector, projected to escalate from $171.98 billion in 2025 to $271.30 billion by 2032. This growth, with a compound annual growth rate of 6.73%, highlights the crucial role machinery like Tig Machines will play in facilitating construction and other industrial activities worldwide.

As industries adapt to these changes, it’s vital to stay informed about innovative solutions that can streamline operations. **Tip:** Embrace automation and smart technologies to optimize production efficiency and reduce costs in your operations. Furthermore, global supply chains must become more resilient; the evolving landscape requires businesses to rethink sourcing strategies and logistics management. **Tip:** Diversifying suppliers and regionalizing production can help mitigate risks associated with geopolitical uncertainties.

The rise of advanced technologies, such as laser welding, which is projected to reach $2.9 billion by 2035, further underscores the necessity for industries to adopt cutting-edge practices. This trend not only enhances product quality but also signifies a transition towards more sustainable manufacturing processes. **Tip:** Invest in research and development to stay ahead of market trends and ensure your operations are aligned with future demands.

| Dimension | Current Value | Projected Growth (2025) | Impact on Global Trade |

|---|---|---|---|

| Market Size (Billion $) | 150 | 200 | Increased access to international markets |

| Export Rate (%) | 30 | 40 | Strengthened global partnerships |

| Innovation Score | 75 | 85 | Enhanced competitive advantage |

| Sustainability Rating | 4.2 | 4.5 | Positive effects on global supply chains |

| Customer Satisfaction (%) | 85 | 90 | Higher brand loyalty internationally |