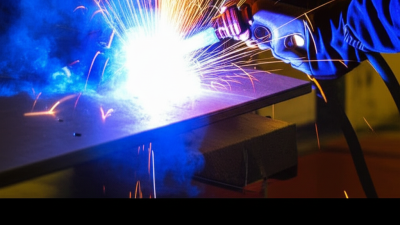

Welding is an art and a science. Having the right tools is vital for success. TIG welding, in particular, requires precision and the right techniques. Recent industry reports indicate that over 60% of welding errors arise from improper equipment use and poor technique. A skilled operator can create strong, clean welds using a TIG machine. However, mastering this skill is not without challenges.

Understanding how to effectively use a TIG machine is essential. Common issues include inconsistent arc stability and contamination. According to the American Welding Society, improper gas coverage can lead to defects. Hands-on experience is crucial for improvement. Operators must learn to troubleshoot common problems, like overheating or poor penetration.

Welding is evolving. New technologies emerge regularly. Staying updated is necessary for welders aiming for perfection. Yet, practical skills remain the foundation of quality work. As the industry grows, so do the complexities of welding processes. There is always room for reflection and improvement in mastering the TIG machine.

Choosing the right TIG machine can significantly impact your welding results. Consider factors like power, duty cycle, and material compatibility. A recent industry report highlights that 45% of welders prioritize power output. Matching the machine's capabilities with your project requirements is crucial.

Think about the duty cycle. This measure indicates how long the machine can operate before it needs a cooldown. For light projects, machines with a 20% duty cycle might suffice. However, for industrial tasks, a machine with a 60% duty cycle is advisable. Remember, using a machine beyond its limits can lead to overheating and damage.

Material type also matters. Aluminum requires different settings than stainless steel. Many welders struggle with inconsistent results due to improper machine settings. Research suggests that 35% of novice welders face issues adjusting their machines for different metals. Ensuring you understand your machine's capabilities will save time and prevent frustration. Making the right choice involves balancing power, duty cycle, and material type to achieve optimal results.

When it comes to TIG welding, understanding essential settings is crucial. The amperage is key. Higher amps melt thinner materials faster. However, too much heat can warp the metal. Always adjust your settings based on material thickness. Try starting with a conservative setting. You can fine-tune as you become more familiar with your work.

Gas flow is another important parameter. A common mistake is using too much gas. This creates turbulence and can lead to oxidation. Aim for a consistent flow. Most projects require around 15 to 20 cubic feet per hour. Testing the gas flow before starting your weld helps prevent issues.

Electrode angle matters too. A slight tilt can change bead appearance and penetration. Experiment with different angles to see what works best. Do not shy away from making mistakes in this process. Each challenge offers a lesson. Learning from them is essential for improvement. Adjust your technique based on the results you achieve.

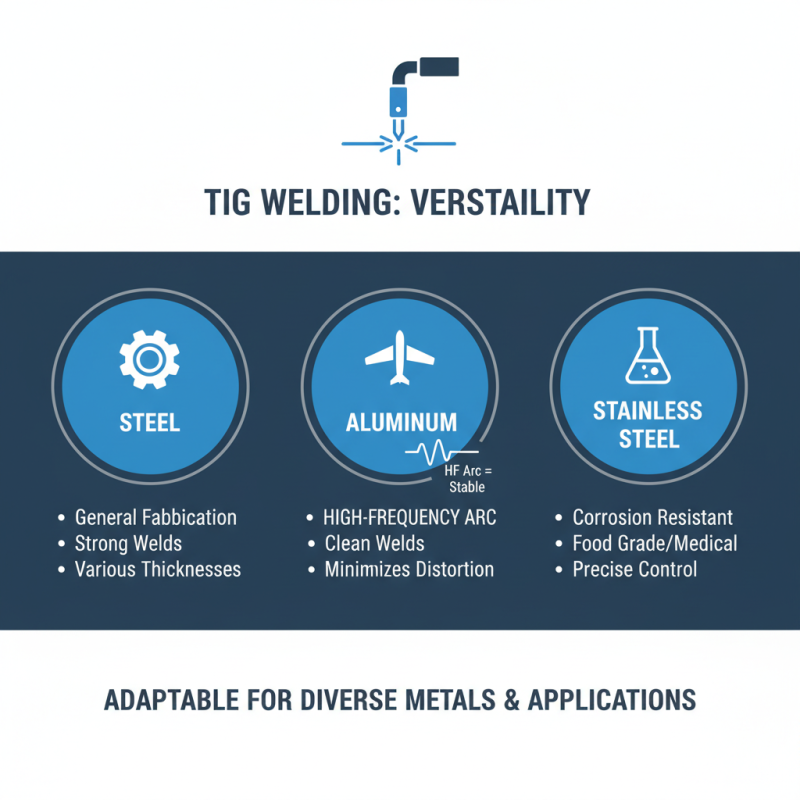

TIG welding is versatile. It works for various metals, including steel, aluminum, and stainless steel. Each metal requires a specific approach. For aluminum, using a high-frequency arc is essential. This helps stabilize the arc better. It allows for cleaner welds and minimizes distortion.

Stainless steel welding demands attention to detail. A non-directional bead pattern can enhance the appearance. Ensure proper heat settings to prevent warping or burn-through. Many beginners struggle with controlling the arc length. It’s important to practice keeping a consistent distance for better results.

When working with mild steel, proper preparation is key. Clean the surfaces thoroughly to remove any contaminants. Using the right filler rod can make a significant difference. New welders often overlook this, leading to weaker joints. Reflecting on these basics improves quality and efficiency.

TIG welding requires a high level of safety awareness. Protective gear is essential. Use a welding helmet, gloves, and fire-resistant clothing. These items shield you from sparks and intense light. Eye protection is non-negotiable. Inadequate lighting can lead to accidents. Ensure your workspace is well-lit and organized.

Ventilation is crucial, especially in enclosed spaces. Fumes can be harmful. A dedicated exhaust fan helps clear the air. Always have a fire extinguisher nearby. Welding materials can ignite quickly. Be aware of flammable materials in your surroundings. Store them safely and clean your workspace often.

Practicing best techniques improves safety. Maintain a steady hand; shaky movements can cause misalignment and waste materials. Adjust the arc length correctly. Too short or too long can be problematic. Reflect on your technique after each session. Mistakes provide valuable lessons that enhance your skills. Embrace the learning curve and prioritize safety at every step.

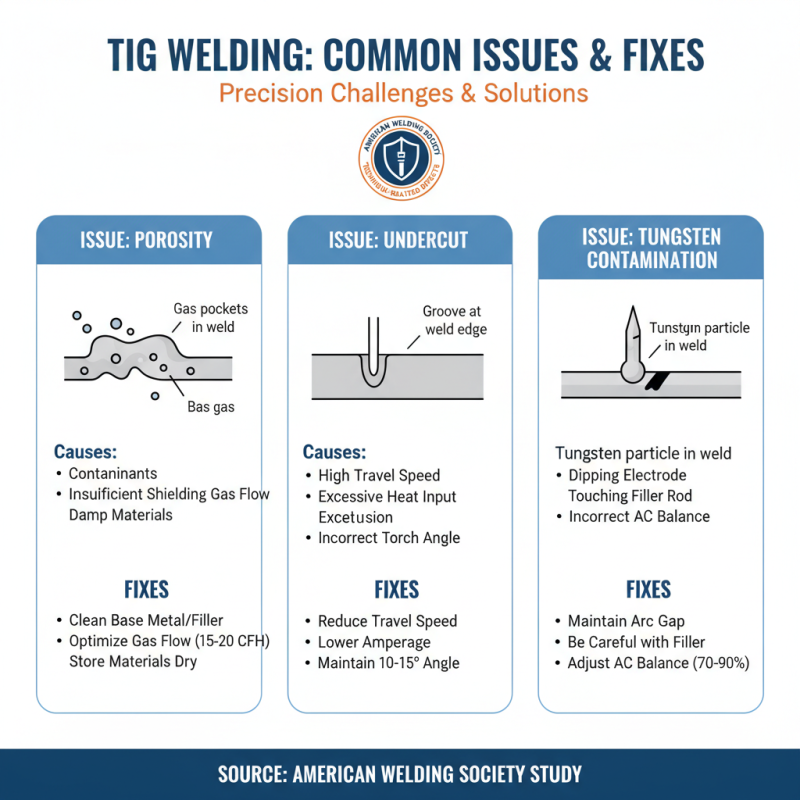

TIG welding is known for its precision, but common issues can arise, affecting the quality of welds. A study from the American Welding Society noted that improper technique leads to 25% of welding defects. Many welders face issues like porosity, undercut, and tungsten contamination. Each of these problems frustrates professionals and requires specific troubleshooting.

Porosity often appears as small pinholes. This defect is caused by impurities in the base material. Ensuring a clean surface before welding can reduce its occurrence. A clean welding environment is crucial. It’s recommended to use a brush or grinder to remove contaminants.

Tungsten contamination can ruin a perfect weld. When the tungsten electrode touches the molten pool, it melts into the weld. Regularly inspecting the tungsten's condition is essential. A well-maintained electrode length helps with a stable arc. According to the Lincoln Electric Company, a well-sharpened tungsten can improve arc stability by up to 70%. Proper preparation and maintenance may seem obvious, but they’re overlooked too often. Acknowledging these flaws allows welders to improve their craft.