Strategically, in this pivotal time of industrial evolution, more and more welding machines are required to meet project productivity and efficiency aspirations. The global market for welding machines is a challenging one to operate in, and selecting reliable manufacturers is important for the best return on investment. Moreover, as more alternate options become available, an even greater emphasis must be laid on determining which of the companies boast not only of durability and performance but also competitive rates with respect to their offerings.

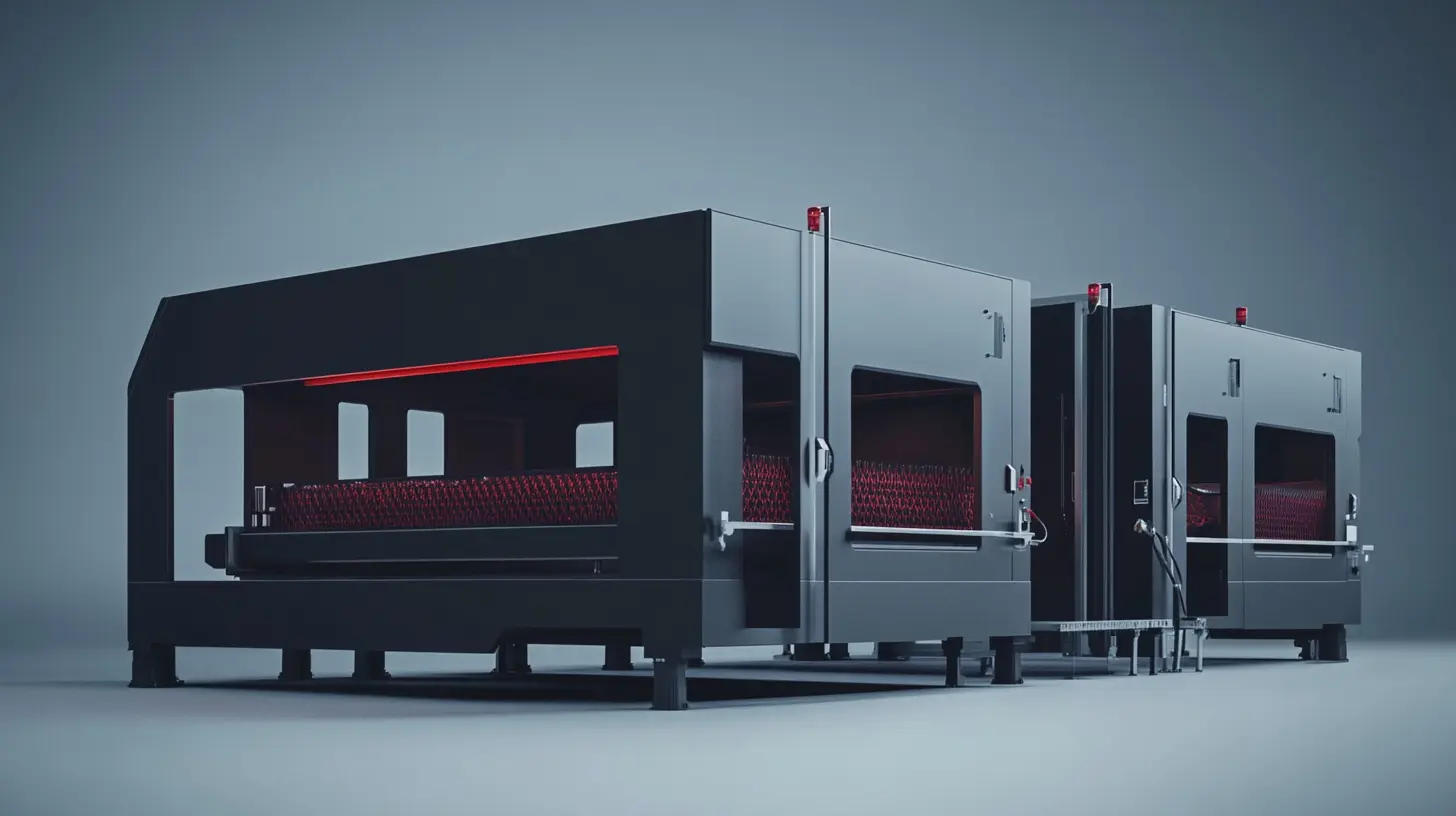

In this respect, TAIZHOU YIKE MACHINERY CO., LTD remains special in the marketplace with the design of many inverter welding machines. Based in Xiayangzhang, Daxi Town, Wenling City, Zhejiang, P.R.China, we enjoy easy access to the Taizhou Airport and the Ningbo and Shanghai ports for our logistic needs. We focus on high production standards while keeping our prices on the lower side to meet our clients' many and varied needs and to smoothen their paths in the convoluted world of the global welding machine market.

When searching for welding machines, one must hold several criteria in mind that are hallmarks to the best in the industry. Firstly, certification and compliance with industry standards are important. Manufacturers conforming to international certifications like ISO 9001 or CE uphold the ideals of quality and safety. These certifications signify competent machine builds to execute reliable, efficient welding processes that are vital in any production environment. Secondly, consider the experience and competence of the manufacturer in this field. Manufacturers that have been in business for a long time often possess vast experience and much innovation with their designs. That experience comes in handy when it comes to reliability but also sprays off to customer service and support options. A manufacturer that knows the ins and outs of welding technology can better address specialized requirements, whether these lie in automation, material compatibility, or varying welding modes. Finally, consider customer reviews and feedback for the manufacturers in question. Talking to former customers can glean insight into how well the machines perform and how durable they are. A manufacturer concerned about customer satisfaction usually has a strong support system comprising equipment warranties and after-sales services. With a focus on these three criteria—certification, experience, and customer feedback—a buyer can feel assured while traversing the global market choosing a welding machine manufacturer best suited to their needs.

One important thing to realize here is that total understanding of global supply chain dynamics in welding equipment is necessary before you invest in what matters to high-quality welding machines. It is the most complex inter-connected market arising from fluctuations caused by sources of raw materials, labor costs and then pumped upon with technical advancements. Countries such as Germany and Japan spearhead this pace of quality standards and innovation because they are the world's largest manufacturing nations. When one understands these supply chains, he or she understands the sources for equipment strong enough to use themselves.

Oh yes. In fact, one must include geographical conditions under which such supply chains operate. Areas with industrial setups are usually in a better position to give their customers high-quality welding machines together with reliable and fast customer support sections. For example, manufacturers whose factories are set up in polities most so-called urban areas have shorter transport times and thus reduced costs for transporting goods from their very factories to major markets. Most importantly, this makes communication and adaptability possible, which are critical during sourcing.

Moreover, the proliferation of online digital platforms has helped to alter the manner in which buyers get to interface with their suppliers. The availability of fast, real-time data and analytics makes it possible for productivity enhances to optimize the stream of supply to give a quick and effective supply response to the market demand. Buyers who understand these transformations digitized qualify potential honest manufacturers by their commitment to quality and efficiency. The welding and cutting equipment market continues to evolve, and one must, therefore, stay informed on supply chain dynamics to ensure that as a buyer one makes informed buying decisions.

While navigating the global market of welding machines, the certification standards and compliance would be key aspects to determine the true quality of manufacturers. The welding machine is adjudged based on safety and performance standards, which are set by organizations such as the International Organization for Standardization (ISO) and American National Standards Institute (ANSI). Grand View Research has reported that the welding equipment market worldwide is expected to reach $25 billion by 2025, which reflects a great opportunity for investment in reliable welding equipment that meets rigorous safety standards.

Another certification worth looking into is ISO 3834, denoting a manufacturer's commitment to quality management systems in welding. This standard also confirms consistent high-quality weld production from the machines. Another meaningful one is CE marking, which suggests the products elucidate with EU safety, health, and environmental protection standards. The demand for certified welding equipment has increased in recent years, mainly due to the construction, automotive, and aerospace industries, which have been pressuring certification to lower the risks associated with below-par machinery.

In addition, compliance with local regulations is crucial for manufacturers inclined to export products. For instance, welding machines must comply with OSHA standards in the USA. Non-compliance could be heavily penalizing and could even restrict market access. Besides, industry reports state that about 40% of the welders mark equipment compliance as a crucial concern, hence emphasizing the relevance of manufacturers who conform to high certification standards and safety as well as regulatory requirements.

The welding industry changes rapidly, subject to several competitive factors, mostly rapidly advancements in automation technologies. Manufacturers continue to seek efficiencies and higher precisions while considering the purchase of automated welding solutions, and by indeed maintaining the worldwide competitiveness of businesses, this trait becomes part of high-production processes with resolution of high amounts of human errors at the time of high-quality outputs.

More closely related to the increasing need for adoption of robotics in welding processes are recent market survey reports that show the increase in the number of sectors, including membership into the automotive industry, the construction industry, or even the aerospace industry, seeing the advantages associated with speedier production points and welding consistency as a direct consequence of automating processes. There is further promise of machine intelligence when coupled with the windows of opportunities machine learning throws open for truly intelligent welding machines that will operate under different conditions while optimizing total performance in real time.

Again, embracing holistic transformation when it comes to automation in welding is what the landscape has been changing for manufacturers itself. Such must be modernized because high-quality producers would really be those utilizing up-to-date technology and stringent checks with regard to the quality to draw inferences for manufacturers under which they can relate in terms of R&D. In fact, collaborating with manufacturers interested in R&D will also expose one to the most sophisticated welding solutions that will likely create favorable competitive conditions in future success. As this progresses, automation-oriented companies will remain at the forefront in innovating and defining efficiency in position with welding.

Knowing the comparative strengths of MIG, TIG, and Stick welding is essential in selecting the most apt Welding technology for your project. Each offers distinct advantages for the performance of different applications and skill levels. MIG (Metal Inert Gas) is beneficial for speed and versatility and therefore will serve both novices and experienced welders well. A concrete flow of metallic wire acts as an electrode and allows for welds made much faster than for other types, making them ideal for thin materials.

TIG (Tungsten Inert Gas) welding, on the other hand, offers the most control over the pool, which could be very useful when deploying more complex work and when using very thin gauge metals. Though it takes more skill to get really good at it, TIG welding is the name of the game for beautiful, exact welds that don't usually have any flaws. It's becoming very popular among DIYers as they can score inexpensive tools during seasonal sales events, making the investment of having a good TIG welder at home quite affordable for personal projects.

Stick welding thing (SMAW or Shielded Metal Arc Welding) is probably the most tried-and-true process, valuable for its sheer simplicity and effectiveness in outdoor environments. Moreover, it is one of the highly prized uses that can be employed in agricultural settings for farm equipment repairs. For most people, it is considered the most rugged task. Best for remote locations, Stick welding provides great flexibility with low minimal setup, allowing one to quickly and easily make repairs in field conditions.

Recent times have seen the developments in welding electronics giving rise to multiprocess machines that combine MIG, TIG, or Stick welding upon a single machine. Such innovations also have increased the portability of welders while adding versatility for the many projects they can help in. High-end welding machines at the global market level are to be viewed keeping in mind the strengths of these methods in relation to your own needs-whether it is for an intricate design or robust fieldwork.

While journeying through the global market for welding machines, the leverage of customer reviews and testimonials goes a long way in identifying the great manufacturers for their purposes. Public reviews place a plank upon the actual performance and dependability of the manufacturer so that a person can ascertain whether or not the welding machine will fulfill his or her particular necessity. Thus, customer feedback gives insight on the course of durability, performance, and after-sales service, which are the most necessary aspects for an outlay.

Furthermore, client testimonials can throw light on a manufacturer's efforts for meeting global standards and newest regulations. This is crucial after the Spanish government increased indirect taxation on one-use, unrecycled plastic packaging. Such legislation shows that the industry is being compelled toward sustainability, stressing the importance of preferring manufacturers who maintain conformity with their environmental commitments. Big stakes are demanded from manufacturers that not only render top-quality welding machines but are also responsibly involved with sustainability compliance through up-to-date regulations.

Hence, investment it would not be out of place to say that feedback from clients is helping in shaping a course that in particular also provides the companies with the kind of transparency valuable for successful partnerships. To that end, one has to very critically engage with these reviews and weigh both positives and negatives, to obtain an overall view on what might be observed or should be expected on the investment scale regarding welding machinery in the global context.

Emerging markets have turned out to be an increasingly considerable source of welding machines. It is both a boon and a bane for businesses in search of superior-quality machinery. India, Brazil, and Vietnam have seen much activity and development in their industrial sectors related to modernization and infrastructure growth. With prospectives of an expanded developing market, a wide variety of manufacturers will, in time, be available, each having their special capabilities and offerings for their customers. This makes it a much more appealing location for people who wish to invest in welding machines.

While entering these emerging markets, it becomes important for businesses to research thoroughly possible manufacturers. Some of the factors that require consideration include manufacturer reputation, quality of products, and adherence to international standards set for the products. Being part of associations or industry groupings for localized businesses may result in finding valuable leads toward reputable suppliers and connecting with them. Furthermore, attending trade fair shows or exhibitions in these regions can open up an advantage of physically relaying experience of the machinery as well as creating bonds with manufacturers toward informed purchasing decisions.

It also entails knowing the specification of the targeted market. Different areas would therefore have solutions that differ based on local regulations, availability of materials and skilled labor. By identifying manufacturers who are willing to customize their welding machines, businesses can gain a competitive advantage and ensure long-term success in the international market.

While searching for a high-quality welding machine in the global market, considering the aftersales support and service offerings from the manufacturer becomes as important as any other factor. This has further reinforced the idea that customers must be guaranteed of robust after-sales support by the manufacturer since it would uplift the overall experience and efficiency of operations. Such support comes in different kinds, such as maintenance services, spare parts availability, and technical assistance, which are of utmost importance for reducing downtime and increasing the lifespan of equipment.

Most importantly, you must consider the response time and availability of the support team. If a manufacturer has a 24/7 customer support system and has few minutes of response time, it means the manufacturer is there for its customers. It is better to read some reviews or ask for testimonials of other customers about after-sales services. This may let you know how a manufacturer tackles problems during after-sales services and how good a supporting system is during these critical times.

Another salient aspect is understanding the quality and breadth of training and other resources that the manufacturers provide for driving user knowledge about their welding machines. Most of the top manufacturers now provide very extensive manuals, online resource access, and training sessions, all of which will empower your in-house workforce to do maintenance and troubleshooting as required. An extended spending period on selecting a manufacturer that spends a great deal of time on after-sales support has proved to be very beneficial in terms of saving costs and improving productivity in the long-term business operations.

Certification standards are crucial as they help identify high-quality manufacturers and ensure that welding machines adhere to safety and performance benchmarks, which is essential for minimizing risks associated with substandard equipment.

ISO 3834 is a certification that indicates a manufacturer's commitment to quality management systems in welding, ensuring that the machines can produce high-quality welds consistently.

CE marking indicates that welding products meet safety, health, and environmental protection standards set by the European Union, ensuring compliance for market access in Europe.

Non-compliance with regulations such as those set by OSHA can lead to severe penalties and restrict market access for manufacturers looking to sell their equipment in the U.S.

There is a growing demand for certified welding equipment in industries like construction, automotive, and aerospace, driven by the need for compliance and to mitigate risks associated with low-quality machinery.

Businesses should look into the manufacturer’s reputation, product quality, and adherence to international standards, as well as engage with local industry groups for insights and connections.

Attending trade shows or exhibitions allows companies to test equipment firsthand, gather information about different manufacturers, and build relationships that can lead to informed purchasing decisions.

Understanding the specific needs, including local regulations and availability of materials, helps businesses find manufacturers that can customize their products, thereby enhancing competitive advantage in the global market.