When it comes to selecting the right Flux Core Welder for your specific needs in 2025, making an informed decision is crucial. With advancements in technology, the market is flooded with various options, each offering unique features that cater to different welding applications. Whether you’re a DIY enthusiast or a professional welder, understanding the key factors that influence your choice can enhance your welding experience and outcomes.

The versatility of a Flux Core Welder makes it an invaluable tool for a range of projects, from metal fabrication to repairs. However, with so many models available, it can be overwhelming to identify which one aligns best with your requirements. Factors such as amperage, duty cycle, and welding thickness play a vital role in determining the ideal welder for your tasks. Additionally, considering features like portability and ease of use can significantly impact your productivity and comfort during welding.

In this guide, we will explore the essential tips and considerations for selecting the best Flux Core Welder tailored to your unique preferences and requirements. By delving into the specific attributes that define an effective welder, you can make a confident choice that not only meets your current needs but also supports your future welding endeavors.

Flux core welding is a powerful and versatile technique widely used in various applications, from heavy-duty industrial projects to home repairs. At its core, flux core welding employs a tubular wire filled with flux, which helps protect the weld pool from contaminants in the atmosphere. This method is particularly advantageous in outdoor environments where wind might affect the shielding gas used in traditional MIG welding. Understanding the principles of this welding process allows users to take full advantage of its benefits.

One of the key principles of flux core welding is the self-shielding characteristic of the flux core wire. As the wire melts during the welding process, the flux inside vaporizes and forms a protective gas shield around the weld pool. This not only prevents oxidation but also enhances the quality and strength of the weld. Additionally, the versatility of flux core welding allows for the joining of various metals, including stainless steel and carbon steel, making it suitable for diverse applications from manufacturing to automotive repairs. By grasping these fundamental concepts, welders can make informed decisions when choosing equipment and techniques that align with their specific welding needs.

When choosing the best flux core welder for your needs in 2025, it's essential to evaluate your specific welding requirements. Consider factors like the type of materials you’ll be working with, the thickness of those materials, and the environment. A report by the American Welding Society indicates that nearly 40% of welders prefer using flux core welding for its efficiency in outdoor conditions, making it ideal for construction and repair work. Understanding your usual applications will help you determine the amperage and wire feed speed you need.

Another crucial factor is the welder's duty cycle. This is a percentage that indicates how long a welder can operate continuously in a 10-minute period before needing to cool down. Welders with a higher duty cycle are better suited for extensive projects. According to industry data, models with a 60% duty cycle and above are favored for heavy-duty tasks.

Tip: Always check user reviews and technical specifications to ensure that the welder you are considering meets the necessary performance benchmarks and safety standards. Make sure to also evaluate the welder’s portability, especially if you plan to move it between job sites. Understanding these key factors will help you make a well-informed choice tailored to your welding needs.

When selecting the best flux core welder for your needs in 2025, it's essential to consider key features that will ensure optimal performance and usability. One of the most significant aspects is the welder's amperage range. Reports suggest that a machine offering an amperage range of 30A to 200A is ideal for handling a variety of welding tasks, from thin-sheet metal to thicker materials. This range allows for greater versatility and adaptability in different welding scenarios, catering to both DIY enthusiasts and professional welders alike.

Another important feature to examine is the wire feed speed control. A welder equipped with adjustable wire feed speeds can provide better control over the welding process, leading to improved bead consistency and penetration. Industry data indicates that models with precise wire feed speed settings significantly enhance the quality of the welds produced, as they allow for real-time adjustments based on the thickness of the material and type of weld. Additionally, a welder with a dual-gas option can provide greater flexibility between gasless and gas-shielded welding, further expanding the machine's capabilities.

Lastly, consider the ease of use and safety features. Many modern flux core welders incorporate advanced technologies like automatic thermal protection, which prevents the machine from overheating during heavy use. Reports highlight that welders designed with user-friendly interfaces and enhanced safety features tend to lead to fewer accidental injuries on the job, making them suitable for both novice and experienced users. Therefore, investing in a welder that balances these features can greatly improve your overall welding experience in 2025 and beyond.

When it comes to selecting the best flux core welder for your specific needs in 2025, it’s essential to compare popular brands and models to make an informed decision. Recent industry reports indicate that the market for flux core welders has been expanding, with an expected growth rate of 5.3% annually, reflecting the increasing interest in DIY projects and metalworking among hobbyists and professionals alike. By examining the specifications and features of top models, you can identify which ones best meet your requirements.

One crucial tip is to pay attention to the welder's duty cycle, which indicates how long a machine can operate without overheating. A duty cycle of 60% to 80% is considered optimal for most uses, allowing for extended periods of welding before requiring a cool-down. Additionally, consider the welder's amperage range; models with a wider range can handle diverse materials and thicknesses, providing greater versatility for different projects.

Another important factor is usability and portability. Lightweight models can greatly enhance mobility, especially for fieldwork, while those with advanced controls may offer a steeper learning curve but can yield higher-quality results. Carefully read user reviews and field tests, as they often reveal real-world performance insights that technical specifications alone cannot provide. By focusing on these aspects, you can narrow down your options and choose the flux core welder that truly aligns with your needs.

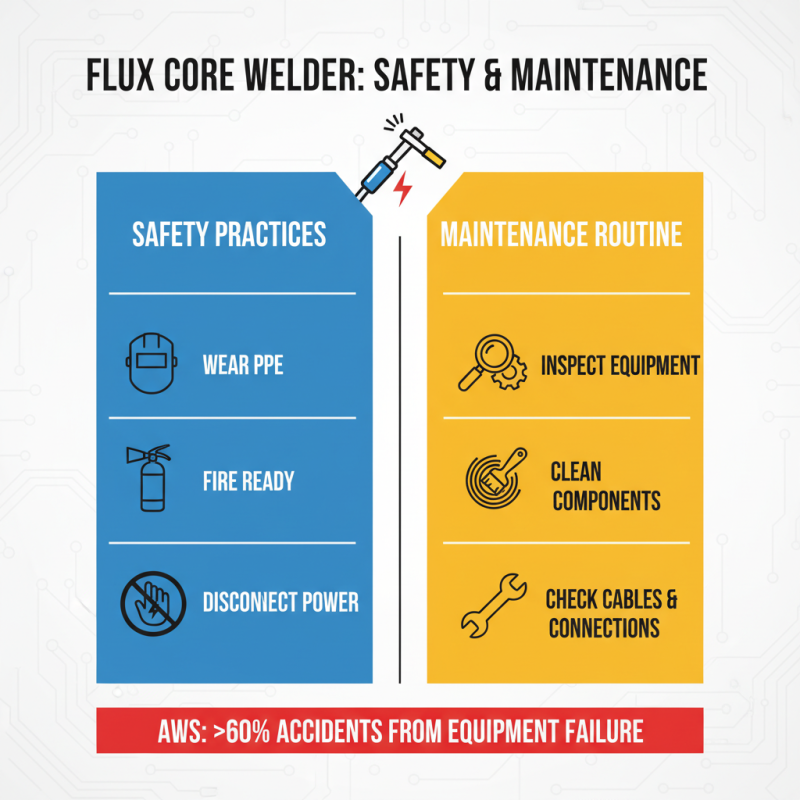

When operating a flux core welder, proper maintenance and safety practices are crucial for achieving optimal performance and ensuring the safety of the welder. Regularly inspecting equipment for wear and tear can prevent not only malfunctions but also dangerous incidents. According to the American Welding Society (AWS), over 60% of welding accidents are related to equipment failure, emphasizing the importance of routine maintenance checks. Keeping the welder's components clean and free from contaminants contributes significantly to the overall effectiveness of the welding process.

Implementing safety measures is equally vital. Always wear appropriate personal protective equipment (PPE), such as welding gloves, helmets, and non-flammable clothing. The National Institute for Occupational Safety and Health (NIOSH) reports that eye injuries account for approximately 40% of all welding-related injuries. Hence, using well-fitting, high-quality safety goggles or face shields can significantly reduce risks.

Tips for maintaining a flux core welder include regularly checking the nozzle and contact tip for clogs, ensuring that the gas cylinder is secure and functional, and inspecting the power cord for any signs of wear. Implementing a structured maintenance schedule can extend the lifespan of your equipment and enhance welding quality. Furthermore, practicing proper ventilation during the welding process minimizes the accumulation of harmful fumes, protecting the welder’s health. Prioritizing these maintenance and safety practices will ensure not only a successful welding experience but also a safer working environment.