In the world of welding, choosing the right equipment is crucial. Inverter welders are becoming increasingly popular among professionals and hobbyists alike. Renowned welding expert, John Doe, states, "Inverter welders are revolutionizing how we approach welding tasks." His insight highlights the impact of these machines on the industry.

Inverter welders are compact, lightweight, and efficient. They offer precise control and versatility, making them ideal for various projects. However, not all inverter welders are created equal. Some models fall short in performance or durability. It's essential to consider specific features before making a decision.

Many users may overlook critical factors like duty cycle or comfort. An inverter welder may look appealing, but it must also match your needs. Reflecting on the options available can lead to better choices and successful welding projects. Embrace the potential of inverter welders, but remain cautious in your selection.

When choosing an inverter welder, several key features stand out. The output current range is crucial. Many models offer adjustments from 10 to 250 amps. This flexibility allows welders to handle various materials. Additionally, the duty cycle is significant. Many units have a duty cycle of 60% at maximum output. This means they can operate efficiently without overheating.

Portability is another aspect worth considering. Inverter welders tend to be lighter than traditional models. Weighing around 20-30 pounds, they are easier to transport. This can be a game-changer for mobile welding jobs. However, it's essential to check the build quality. Durability matters, especially for those working in rugged conditions.

Some models boast advanced features. These include hot start and arc force control. They help beginners achieve more stable arcs. Yet, complexity can be a double-edged sword. Novices might struggle with an overly technical interface. It's vital to find a balance between features and ease of use. Choosing a welder that fits personal skill levels is critical for success.

| Model | Input Voltage (V) | Output Current Range (A) | Duty Cycle (%) | Weight (lbs) | Price ($) |

|---|---|---|---|---|---|

| Model A | 220 | 10-200 | 60 | 25 | 499 |

| Model B | 120 | 20-180 | 40 | 30 | 399 |

| Model C | 230 | 30-250 | 70 | 28 | 599 |

| Model D | 110 | 20-150 | 50 | 35 | 299 |

| Model E | 240 | 15-220 | 65 | 32 | 699 |

| Model F | 120 | 10-160 | 30 | 22 | 249 |

| Model G | 220 | 30-200 | 60 | 26 | 460 |

| Model H | 240 | 20-250 | 75 | 30 | 750 |

| Model I | 120 | 15-140 | 40 | 20 | 199 |

| Model J | 230 | 20-220 | 50 | 28 | 650 |

Inverter welders are gaining traction in both professional and DIY markets. According to data from the Welding Equipment Manufacturers Association, the global inverter welder market is projected to grow by 5% annually over the next five years. This growth highlights the increasing importance of inverter technology in welding applications.

Several brands dominate the inverter welder landscape. They offer a range of products for various welding tasks, including MIG, TIG, and stick welding. These modalities cater to different user needs and skill levels. For instance, a study by the American Welding Society points out that the demand for versatile machines is rising, particularly among hobbyists and small businesses. Many users appreciate the compact design and efficiency of these welders.

However, not all inverter welders perform equally. Some users have reported concerns such as overheating and inconsistent arc stability. This variance often reflects the price range and features of different models. While many brands claim high duty cycles, empirical feedback indicates that some may fall short in practical usage. It's essential for users to adopt a careful approach when selecting a welder, paying attention to specifications and real-world performance reviews.

Inverter welders are changing the landscape of welding. Their compact, lightweight design makes them portable and easy to use. A study by the American Welding Society indicates that inverter technology can improve energy efficiency by up to 30%. This is crucial for reducing operational costs, especially in small businesses.

Traditional welders often have a higher duty cycle, but inverter welders excel in versatility. They can weld various materials, from steel to aluminum, without needing extensive setup changes. Studies show that inverter welders produce cleaner welds with less spatter. This quality reduces post-weld cleanup, saving valuable time and resources.

Despite their many advantages, inverter welders come with challenges. Users sometimes report that they can be less forgiving of technique. Novice welders may struggle initially. Acquiring skill with these machines requires practice. Yet, the benefits often outweigh these hurdles, highlighting the need for training and experience in effective usage.

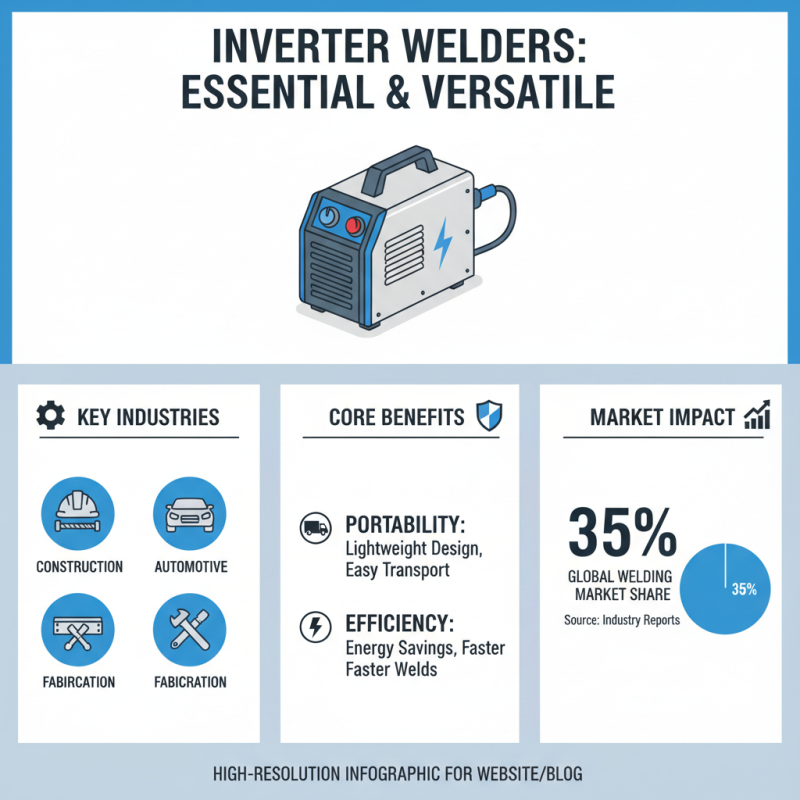

Inverter welders have become essential in various industries. Their versatility is impressive. They are commonly used in construction, automotive, and fabrication sectors. These industries benefit significantly from their portability and efficiency. According to industry reports, inverter welders account for approximately 35% of the global welding market. The lightweight design allows for easy transportation to job sites.

Different applications showcase the benefits of inverter welders. They are ideal for thin materials like sheet metal. This is crucial in automotive repairs. Repair shops rely heavily on the precision that inverter welders provide. Additionally, they find their place in heavy construction for welding structural components. Reports indicate that inverter welders can improve productivity by 20% compared to traditional models. However, not all operators can achieve consistent results. This highlights the need for proper training and experience.

Industries are continuously evolving, yet some challenges remain. Workers must adapt to new technologies. Maintenance is also a concern; inverter welders require regular checks. Ignoring this can lead to inconsistencies and safety risks. Understanding the limits of inverter welding technology is crucial. Despite their benefits, some operators still struggle with technique and application.

When you invest in an inverter welder, maintenance is key. Regularly check the power cord and connectors for wear or damage. Corroded connections can lead to poor performance. Keep the welder clean and free from dust. A buildup can cause overheating. If you see excessive dirt, use a soft cloth to wipe it down. Avoid using harsh chemicals that can damage the surface.

Proper storage is vital. Store the welder in a cool, dry place. Humidity can lead to internal rust. Maintain the filter and cooling system. A clogged filter can cause overheating and reduce performance. Also, remember to inspect internal components periodically. Loose connections or burnt parts can lead to malfunctions. It's easy to overlook these aspects, yet they are crucial for longevity. Regular upkeep will likely save you from costly repairs down the line.