The landscape of welding technology is evolving rapidly. With advancements in Inverter Welding Machines, professionals must stay informed. John Smith, a welding industry expert, once stated, "The future of welding lies in inverter technology." This insight reflects the growing significance of inverter technology in welding operations.

Inverter Welding Machines offer portability and efficiency. These machines are increasingly favored for their lightweight design and precise control. However, challenges remain. Not all users are familiar with the latest features. Some still struggle to harness the full potential of these machines. Education and training are key to bridging this gap.

In 2026, new trends will emerge. Features like digital interfaces and real-time monitoring will become standard. As the industry shifts, professionals need to adapt. Staying aware of trends will ensure success. The journey of mastering Inverter Welding Machines is ongoing and requires continuous learning.

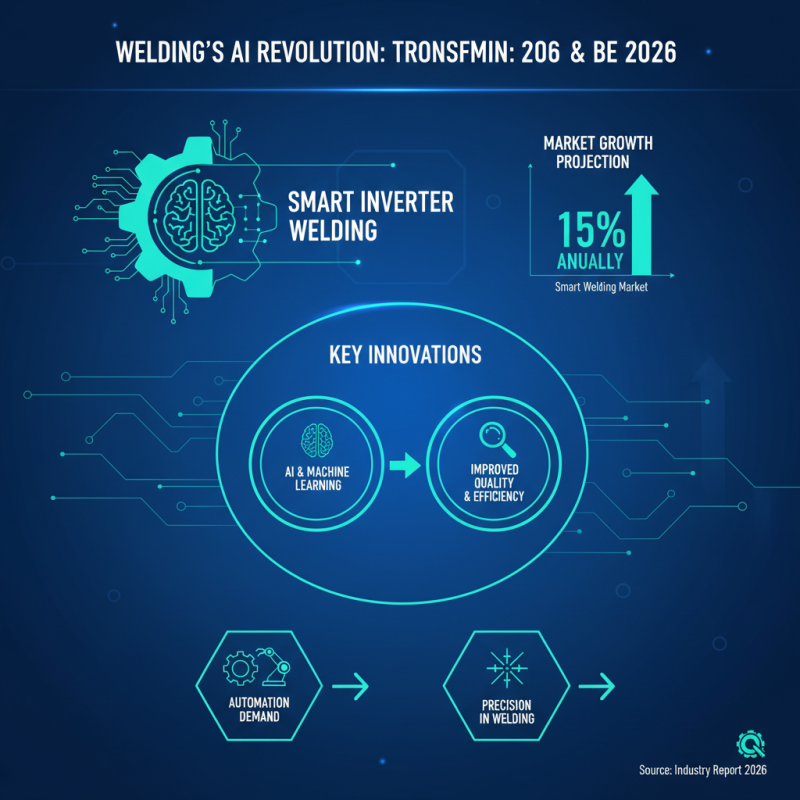

The welding industry is on the brink of a transformation in 2026. The emergence of smart inverter welding technologies is becoming a focal point. These advanced systems use artificial intelligence and machine learning to improve welding quality and efficiency. According to a recent industry report, the smart welding market is projected to grow by 15% annually, reflecting the increasing demand for automation and precision in welding processes.

Smart inverter technologies offer real-time data analysis to welders, providing insights into heat control and material compatibility. Reports suggest that 70% of welders have noted improved accuracy in their work since integrating these smart solutions. However, the cost associated with upgrading to these systems is a concern for many small businesses. Many find it difficult to justify the initial investment, despite the long-term benefits.

Furthermore, the learning curve for new technologies can be steep. Some users report challenges in adapting to new interfaces and functionalities. While smart welding can enhance productivity, it is crucial to address these adoption hurdles. Industry experts emphasize the need for comprehensive training and support to maximize the potential of these advanced welding solutions. The conversation about smart inverter welding is just beginning, and the future holds both promise and uncertainty.

Inverter welding machines are transforming the welding industry, particularly with a focus on sustainability. Eco-friendly technologies are becoming essential as companies seek to minimize their environmental impact. According to recent industry reports, nearly 40% of manufacturers now prioritize green technologies when selecting welding equipment. This trend reflects a broader commitment to corporate social responsibility. The move towards sustainable practices is not merely a trend but a necessity.

These machines reduce energy consumption significantly, often up to 30% compared to traditional models. Additionally, they produce fewer emissions and waste. Many manufacturers are also implementing recyclable materials in their designs. This combination fosters sustainability while enhancing performance and efficiency. Such advancements could lead to an estimated 25% increase in adoption rates over the next few years.

Tips: When choosing an eco-friendly inverter welding machine, consider energy-saving features. Look for models that have a high-efficiency rating. Also, assess the recyclability of the materials used in construction. Small choices can make a significant impact on the environment and operational costs. However, be cautious of misleading marketing; not all “green” labeled products meet strict environmental standards. Keep researching and verify claims before making a purchase decision.

Inverter welding technology is undergoing a transformation with the integration of artificial intelligence (AI). Recent reports indicate that over 40% of welding processes are now automated, enhancing precision in tasks that were once labor-intensive. AI algorithms analyze data in real-time. They optimize welding parameters instantly, improving bead quality and reducing spatter.

However, the adoption of AI is not flawless. Some operators report challenges with training AI systems effectively. There is often a learning curve for both the machine and the user. Misalignment in data can lead to inconsistent results. Interestingly, studies suggest that about 30% of manufacturers still rely on traditional methods. They sometimes see AI as a threat rather than an aid.

Despite these hurdles, the trend is clear: AI can revolutionize inverter welding. As companies invest more in smart technology, the focus will shift towards enhanced training protocols. Exploring human-machine collaboration could bridge the gap. Precision will likely improve, but it requires commitment and adaptation. The future of welding is bright, but the journey is just beginning.

| Trend | Description | Expected Impact (%) | Adoption Rate (%) |

|---|---|---|---|

| AI-Powered Precision | Integration of AI algorithms for better welding accuracy. | 25 | 40 |

| Remote Monitoring | Real-time tracking of welding processes via IoT. | 30 | 50 |

| Smart Controls | Automated adjustments for optimal welding conditions. | 20 | 35 |

| Energy Efficiency | Reduction in energy consumption through advanced technology. | 15 | 45 |

| User-Friendly Interfaces | Intuitive designs for easier operation by welders. | 10 | 60 |

In today's market, small businesses seek cost-effective inverter welding solutions. These machines are lightweight and portable, making them ideal for various projects. Their efficiency can save both time and money, which are critical for small operations. When choosing an inverter welder, look for features that suit your specific needs without overspending.

Tips: Consider the duty cycle. This is how long the machine can operate continuously. A higher duty cycle often means better performance. Also, think about the power supply. Some machines require 220V while others work well with 110V. Knowing your workspace can guide your decision.

Having a reliable inverter welder can significantly enhance productivity. However, not all options are perfect. Sometimes, lower-priced models compromise on quality. Assess the warranty offered. A good warranty can provide peace of mind. Finding balance in budget and quality is essential for long-term success.

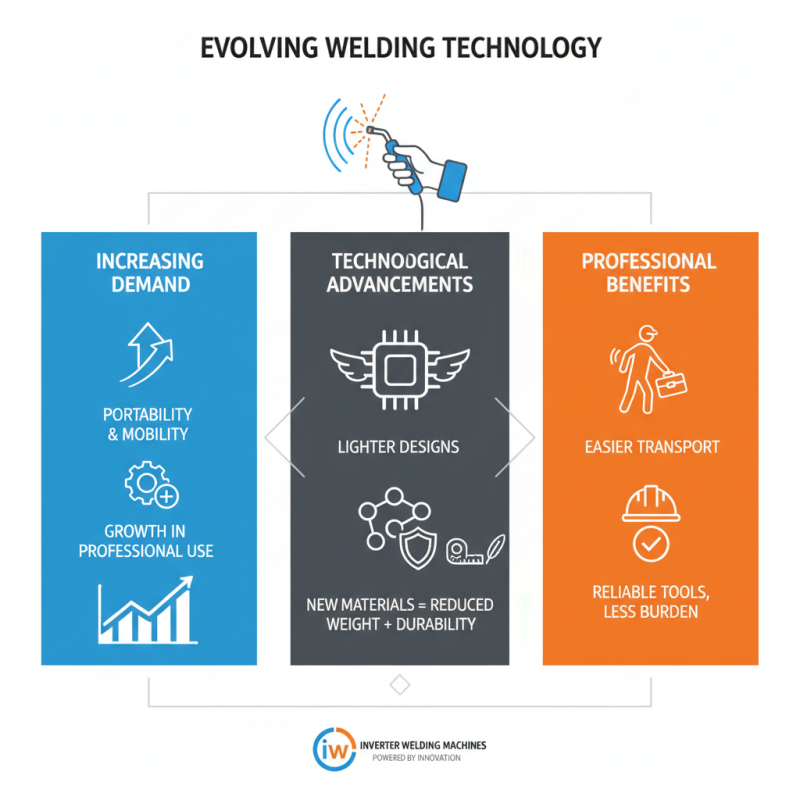

The demand for inverter welding machines continues to grow, especially in terms of portability and mobility. Advances in technology have led to lighter designs, making these machines easier to transport. New materials help reduce weight while maintaining durability. This change is critical for professionals who work at various job sites. They need reliable tools without the burden of heaviness.

Mobility has also improved with innovative carrying solutions. Some machines now come with built-in wheels or ergonomic handles. This feature enhances comfort during transportation. However, some users still struggle with managing their equipment on uneven surfaces. It's a reminder that while technology advances, challenges remain. Users must adapt and find their own solutions for specific environments.

Battery life is another area of concern. While some newer models offer extended battery runtime, not all users find them satisfactory. Recharge times can disrupt workflow. This emphasizes the need for ongoing evaluation of these machines. Balancing convenience with functionality continues to be a central issue in the industry. As we embrace these trends, reflection on practical limitations is essential.