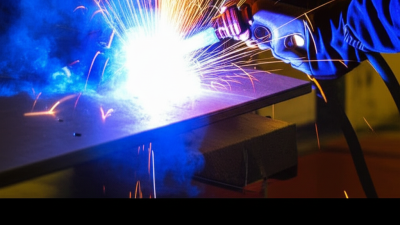

In the world of welding, mastering the TIG machine techniques is essential for achieving superior quality and precision in your projects. Whether you are a novice looking to hone your skills or a seasoned professional aiming to refine your craft, understanding the intricacies of TIG welding can significantly elevate your work.

This ultimate guide will delve into the fundamental techniques, best practices, and troubleshooting tips for using a TIG machine effectively. By exploring various aspects such as equipment setup, material compatibility, and intricate welding patterns, you'll gain the knowledge necessary to enhance your welding capabilities.

Join us as we unlock the secrets to mastering TIG machine techniques, paving the way to exceptional results in your welding endeavors.

TIG welding, or Tungsten Inert Gas welding, is renowned for its precision and versatility, making it a preferred method for various applications, from art to industrial fabrication. At the core of TIG welding is the principle of an electric arc forming between a non-consumable tungsten electrode and the workpiece. This process requires a shielding gas, typically argon or helium, to protect the weld area from atmospheric contamination. Understanding the underlying principles of TIG welding is essential for achieving superior results, as it allows welders to control the heat input and achieve cleaner, stronger welds.

In addition to grasping the principles of TIG welding, having the right equipment is crucial. A quality TIG machine should offer adjustable settings for current and gas flow, enabling the welder to adapt to different materials and thicknesses easily. Essential equipment includes a reliable tungsten electrode, suitable filler materials, and an effective gas delivery system. By mastering the correct setup and these fundamental components, welders can enhance their skill set and produce high-quality welds that stand the test of time. Investing in the right tools and understanding their functions will significantly impact a welder's confidence and quality of work in the field.

This bar chart illustrates the welding quality ratings based on different skill levels in TIG welding. As the skill level increases from Beginners to Experts, the quality rating also improves, highlighting the importance of mastering TIG techniques for superior welding quality.

Mastering the TIG (Tungsten Inert Gas) welding process is paramount for achieving precision and control in high-quality welds. The inherent advantages of TIG welding, such as its ability to provide a stable arc and superior weld seams, make it an essential technique for fabricating thick materials and dissimilar metals. By optimizing process parameters, welders can significantly enhance the quality of their work, creating strong, reliable joints even in challenging conditions.

Recent research emphasizing techniques like the Taguchi method showcases a systematic approach to refining welding parameters. This method focuses on achieving optimal settings for various factors such as gas flow, weld speed, and arc length, ultimately leading to better weld quality and efficiency. Additionally, advancements in machine learning are facilitating the identification of weld integrity, allowing for real-time assessments of conditions like porosity and burn-through. Such innovations not only ensure precision in welding but also address the industry's growing demands for productivity and enhanced quality control in the welding process.

| Technique | Description | Best Application | Skill Level |

|---|---|---|---|

| A-Cycle Tig Welding | Technique focusing on alternating current to stabilize the arc. | Aluminum welding | Intermediate |

| DCEP (Direct Current Electrode Positive) | Common settings for welding non-ferrous metals. | Stainless steel welding | Advanced |

| Root Pass Technique | Ensuring full penetration with a controlled bead. | Pipe welding | Intermediate |

| Weaving Pattern | Side-to-side motion for increased bead width. | Sheet metal welding | Beginner |

| Filler Rod Control | Managing filler rod addition for consistency. | All types of metals | Intermediate |

Setting up your TIG machine properly is crucial for achieving optimal performance and superior welding quality. One of the first best practices involves adjusting the amperage according to the material thickness. Generally, a higher amperage is necessary for thicker materials, while thinner materials require less power to prevent burn-through. Make sure to consult the welding chart that comes with your TIG machine to find the right settings based on your project requirements.

Setting up your TIG machine properly is crucial for achieving optimal performance and superior welding quality. One of the first best practices involves adjusting the amperage according to the material thickness. Generally, a higher amperage is necessary for thicker materials, while thinner materials require less power to prevent burn-through. Make sure to consult the welding chart that comes with your TIG machine to find the right settings based on your project requirements.

Another key tip is to ensure that your filler material matches the base metal. Using the correct filler rod will help achieve a strong bond and maintain the integrity of your weld. Additionally, keep your tungsten electrode sharpened and clean; a sharp point allows for better arc stability and precision. Remember to set the correct tungsten stick-out length for your welding needs, as this can significantly affect the arc properties and overall weld quality.

Lastly, always ensure your torch and gas flow are set correctly before starting your weld. A proper shielding gas flow prevents contamination and porosity, which can weaken the weld. Set the gas flow to approximately 15-20 cubic feet per hour, ensuring a reliable shield around your welding area. These tips will help you unlock the full potential of your TIG machine and enhance your welding results.

When it comes to mastering TIG welding, avoiding common mistakes is crucial for achieving superior quality results. Many beginners struggle with maintaining the correct arc length, which can lead to improper bead formation and weak joints. Ensuring a consistent arc length not only enhances control but also promotes better fusion between the materials being welded. Practicing with varied materials and thicknesses can help you refine this skill, giving you the confidence to tackle more complex projects.

Another frequent pitfall is insufficient cleaning of the workpiece. Oil, rust, or mill scale can severely affect the quality of your welds, leading to defects like porosity or inclusions. Always dedicate time to thoroughly clean the surfaces to be welded, using appropriate methods such as grinding or chemical cleaning. Additionally, controlling your welding speed is vital; too fast can result in inadequate penetration while too slow may cause excessive heat input and distortion. By identifying and rectifying these common mistakes, you can dramatically improve your TIG welding outcomes and elevate your craftsmanship to new heights.

Mastering advanced TIG techniques is essential for welders aiming to elevate their fabrication skills. By integrating modern approaches, such as applying precise cooling and lubrication methods, welders can enhance their performance and achieve superior outcomes. The recent insights into difficult-to-machine alloys highlight the significance of proper cooling strategies, which can drastically improve the machinability and surface finish of welded joints. Techniques like minimum quantity lubrication (MQL) not only aid in reducing heat but also diminish tool wear, resulting in cleaner and more reliable welds.

Moreover, advanced TIG welding benefits from innovations in wire arc additive manufacturing (WAAM), addressing common challenges such as defect formation and property optimization. By embracing these advanced practices, welders can refine their processes and overcome obstacles that traditionally impede progress. Experimentation with different cooling methods in tandem with TIG techniques can lead to breakthroughs in material control and weld quality, ensuring that fabricators stay ahead in the competitive landscape of metalworking.