Causes and treatment of incomplete penetration during welding?

1. Phenomenon

Incomplete penetration is the phenomenon that the root of the joint is not completely melted during welding and leaves a gap.

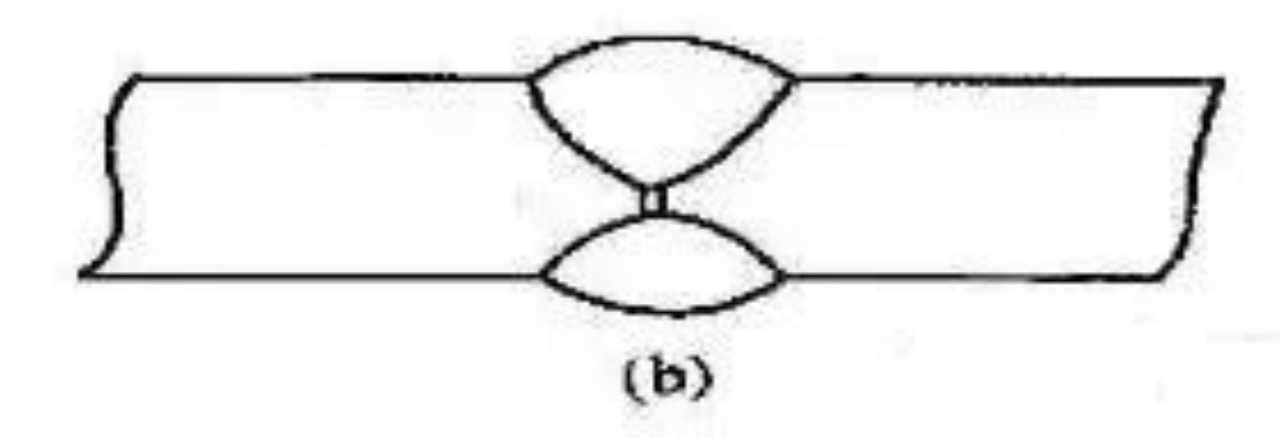

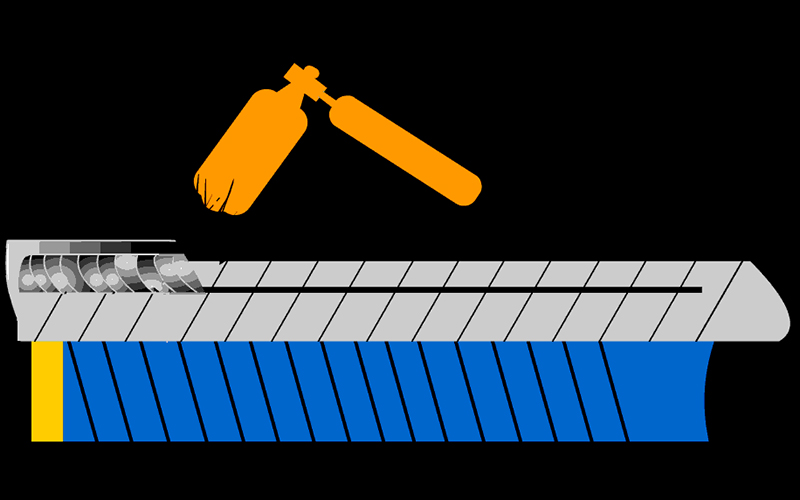

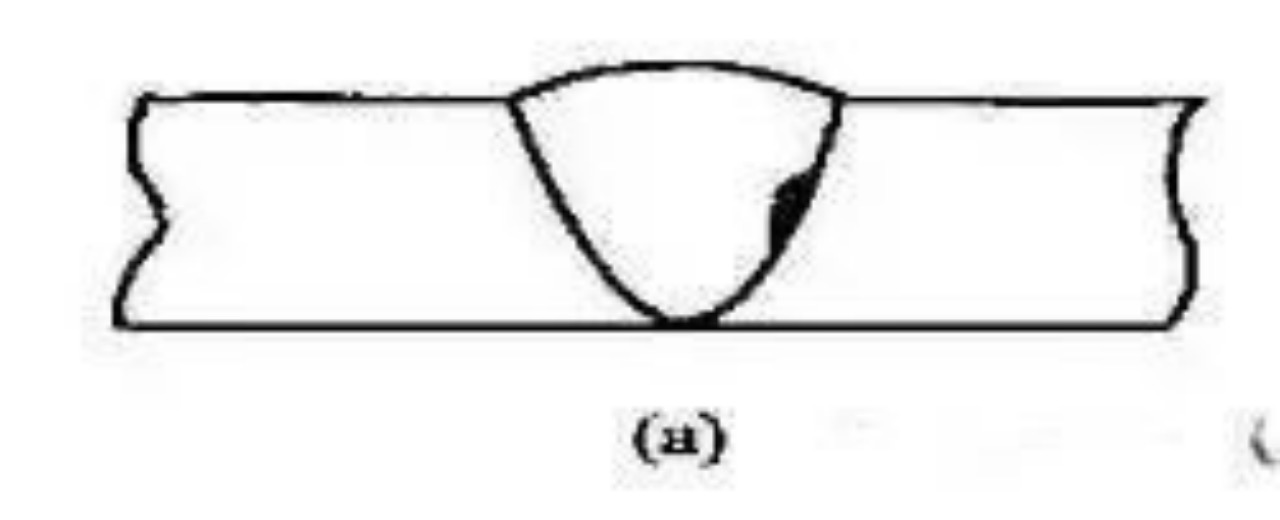

One-sided welding root is not fully penetrated

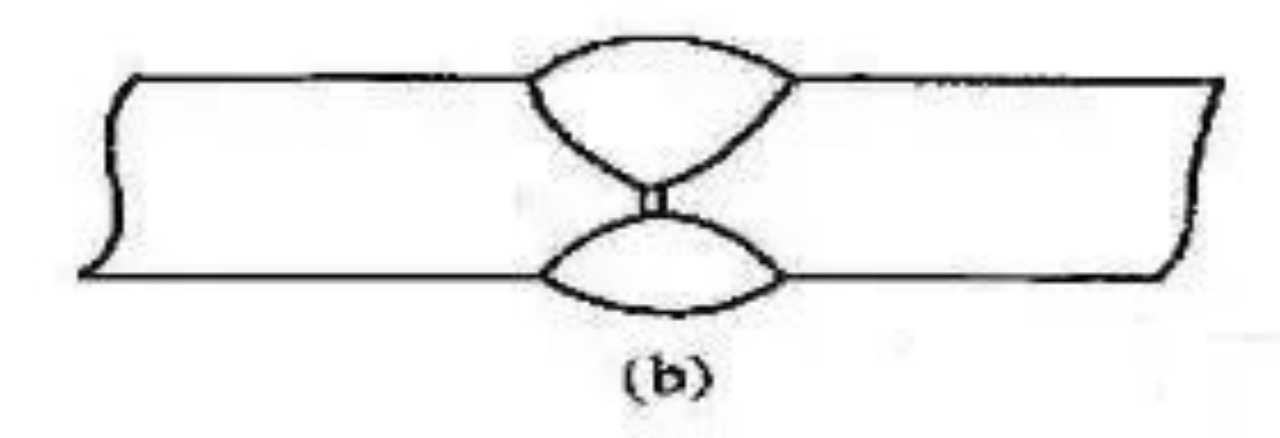

Double-sided welding root is not fully penetrated

2. Hazards

Incomplete penetration reduces the mechanical properties of the joint. At the same time, the notch and end of the incomplete penetration will cause severe stress concentration, leading to cracks.

3. Cause Analysis

(1) The welding current is too small or the welding speed is too fast, resulting in shallow penetration.

(2) The groove angle is too small, the blunt edge is too large, and the root gap is too narrow.

(3) Improper operation angle of the welding rod causes the welding rod to blow, causing the arc heat source to dissipate or deviate to one side, which can easily cause incomplete melting on the other side.

(4) The back side is not cleaned thoroughly during double-sided welding, or oxides, slag, etc. hinder the full fusion between the metals.

4. Preventive measures

(1) Control the groove size and assembly gap according to the specifications, thoroughly clean the weld root, and ensure the root is welded through.

(2) Comply with the welding process, select a reasonable welding current, welding angle and welding speed, and pay attention to the melting of the molten iron at the root. When using an eccentric electrode, pay attention to adjusting the welding angle so that the arc is in the correct direction.

(3) For low alloy steel materials, thick and fast thermal conductivity base materials, preheating is required before welding.

5. Treatment methods

In the welding quality standard, the incomplete penetration defect is not allowed in double-sided welding or single-sided welding with backing plate. For single-sided welding without backing plate, the allowed incomplete penetration defect is related to the importance of the weld. Important welds are not allowed to have incomplete penetration on one side. The defect location should be determined based on the flaw detection results, and the repair location should be determined.

11. Unfused

1. Phenomenon

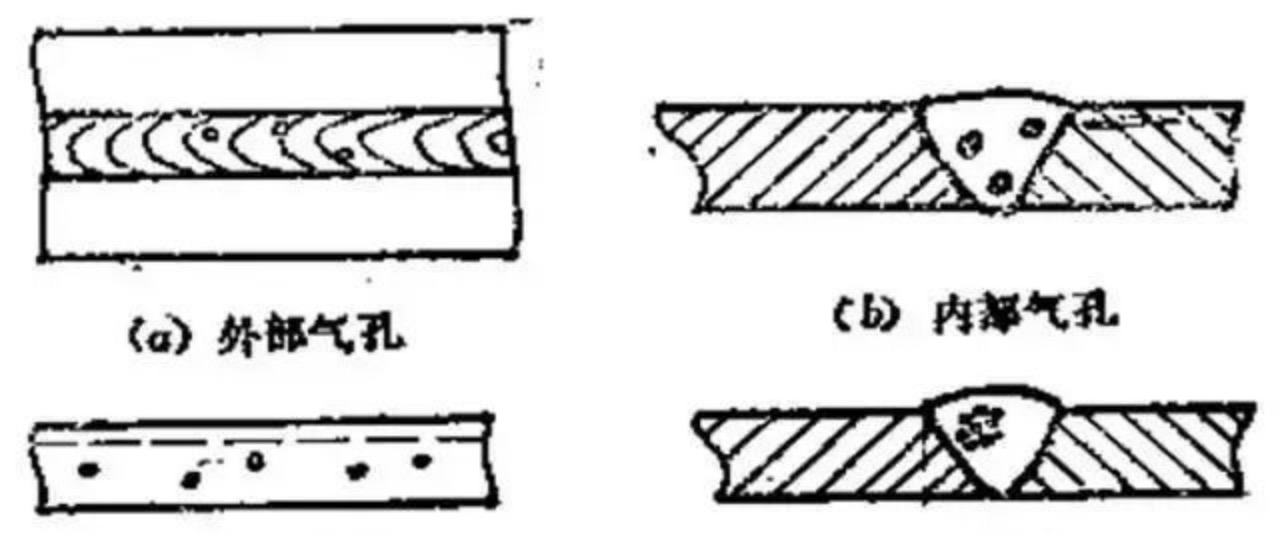

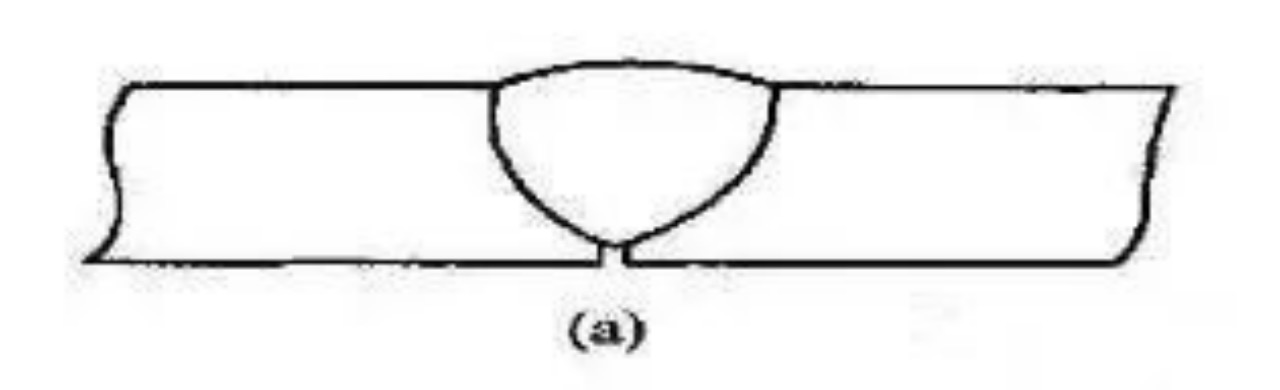

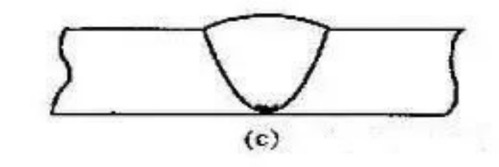

Lack of fusion refers to the part between the weld metal and the base metal or between the weld metal and the weld metal that is not completely melted and combined. It can be divided into side wall lack of fusion, interlayer lack of fusion and weld root lack of fusion side wall lack of fusion

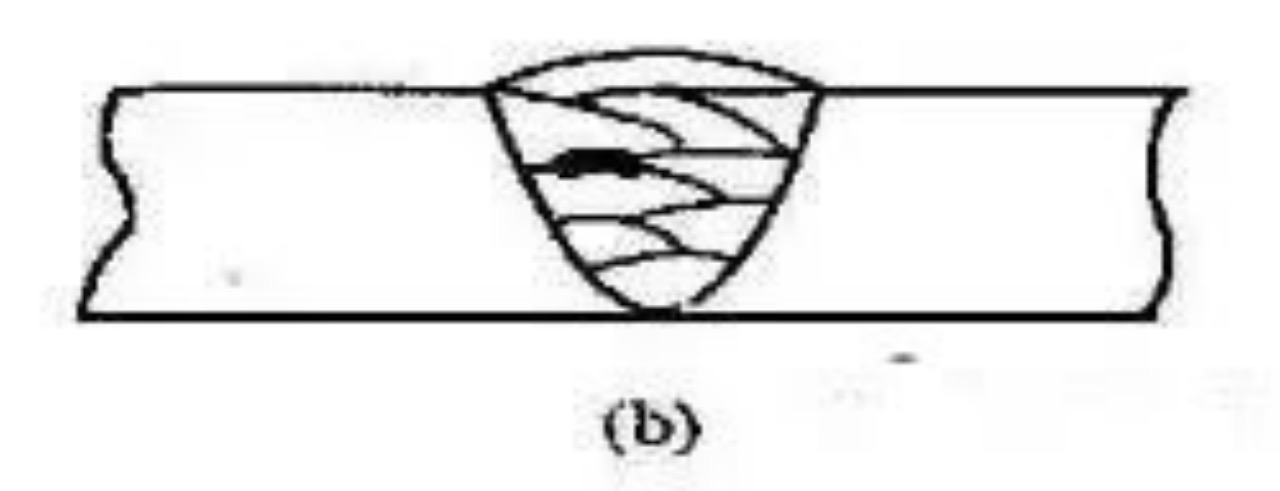

No fusion between layers

Unfused roots

2. Hazards

Lack of fusion reduces the effective cross-section of the joint bearing load and reduces the mechanical strength.

3. Cause Analysis

(1) The reason for the lack of fusion is that the welding line energy or flame energy rate is too small, that is, the welding current is too small or the welding speed is too fast, the welding rod pause time on both sides of the weld is too short or the welding rod angle is biased to one side, so that the base material or interlayer metal is not fully melted and is covered by the filler metal.

(2) When there are oxides or uncleaned slag and other dirt on the groove of the parent material or the surface of the previous weld, if the welding temperature is not high enough to melt and combine them, incomplete fusion will also occur.

(3) The welding temperature is low and the welding speed is too fast, which may cause the weld to not melt at the beginning.

4. Preventive measures

(1) Select reasonable welding process parameters. The angle and speed of the welding rod should be appropriate. The welding rod should be moved slowly at the edge of the groove and stay for a little longer so that the heat is sufficient to melt the base material and the previous layer of weld metal.

(2) The iron oxide in the groove of the parent material and the slag in the weld groove should be cleaned and leveled.

(3) When the electrode is eccentric during welding, the angle should be adjusted so that the arc is in the correct direction.

5. Treatment methods

Generally, incomplete fusion defects are not allowed in welds. When they occur, the defect location should be determined based on the flaw detection results and the repair position should be determined.

TAIZHOU YIKE MACHINERY CO., LTD is located in Xiayangzhang,Daxi Town Wenling City, Zhejiang, China which near to Taizhou airport,Ningbo&Shanghai ports.We are specialized in manufacturing various kinds of inverter welding machine with high quality and favorable price.

Our ISO9001 certifed manufacturing facility provides consistent quality you can count on every turn.Our application-specific engineers and dedicated R&D teams are able tocustomize solutions for optimal performance and value.Our company has abundant strength to research and develop new products of Welding Machines .Our products are manufactured with international technology standard and we had exported to more than 20 countries, such as Brazil,Colombia,Mexico,Spain,Poland and so on.

We are warmly welcome customers from all over the world to establish a long-term &win-win business relationship as well as friendship with us.