The higher the weld reinforcement, the better?

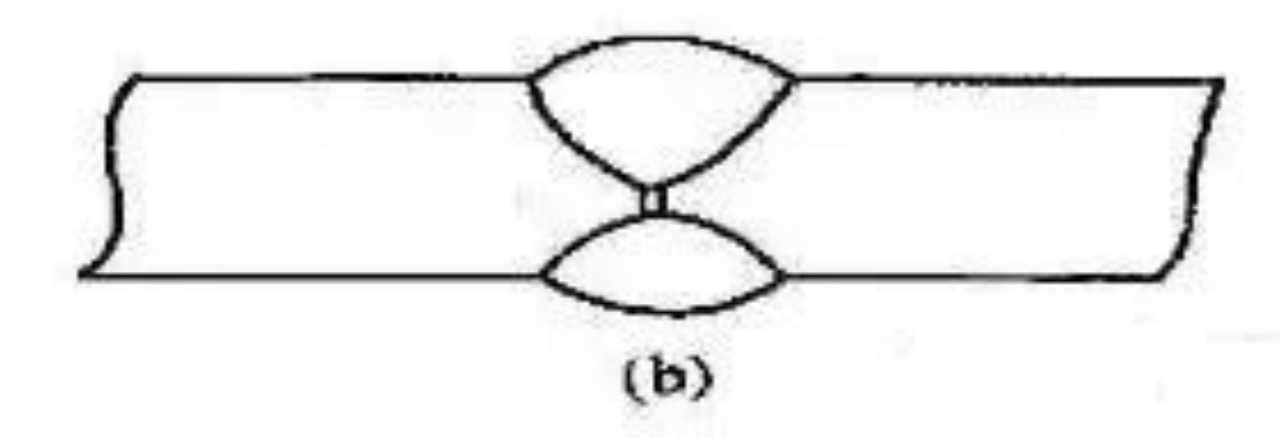

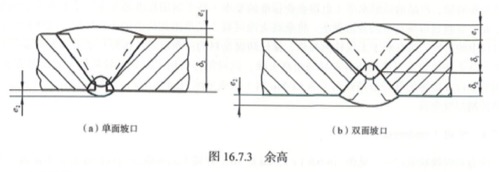

The parts ei1 and e2 in the figure below are the excess height. The excess height is not only required by the welding process, but also has a certain impact on the safe operation of the container, especially the fatigue life.

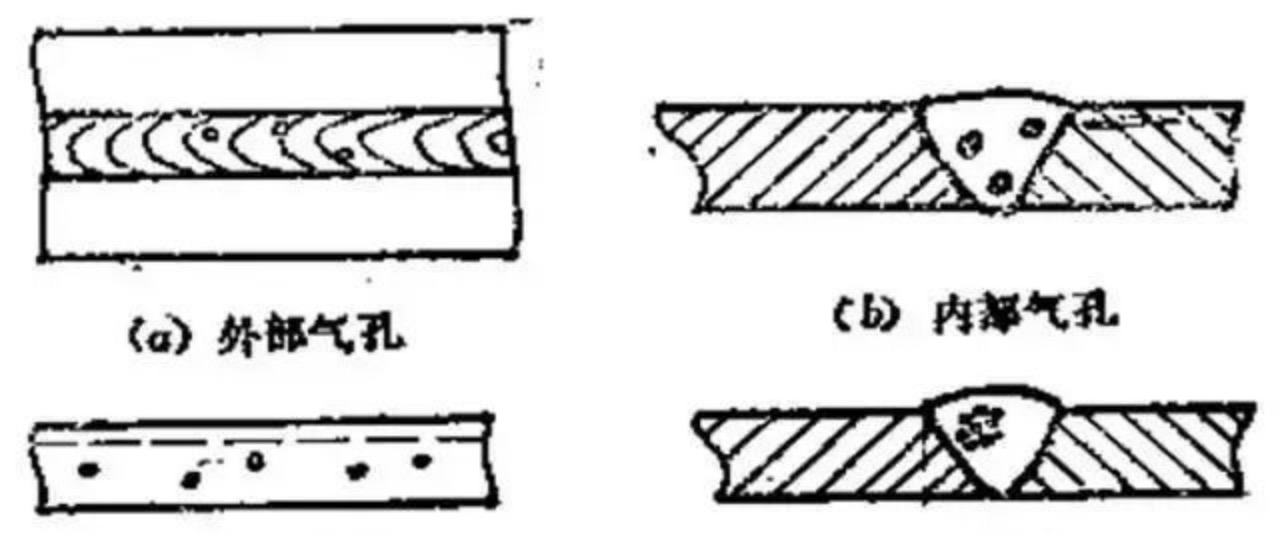

The welding of pressure vessels is mostly multi-pass welding (such as manual welding and automatic welding). The subsequent weld is equivalent to the previous weld to play the role of heat preservation, slow cooling and tempering, and refine the grain of the previous weld.

The reinforcement height is equivalent to the insulation, slow cooling and tempering of the outermost strength weld, so the reinforcement height is a requirement of the welding process.

After the joint is welded, the process function of the excess height is completed. After that, the existence of the excess height will have some adverse effects on the safe operation of the container. The Japanese once made two groups of test containers. One group had the excess height ground off after welding to make the weld flush with the surface of the parent material. This is called the group with the excess height removed.

The other group was not treated after welding and was called the residual height retention group. The two groups of containers were subjected to pressure fatigue tests under the same working conditions to compare their fatigue lives.

The test results show that the container in the group with retained excess height failed first, and the average fatigue life of the two groups differed by 2.1 to 2.5 times.

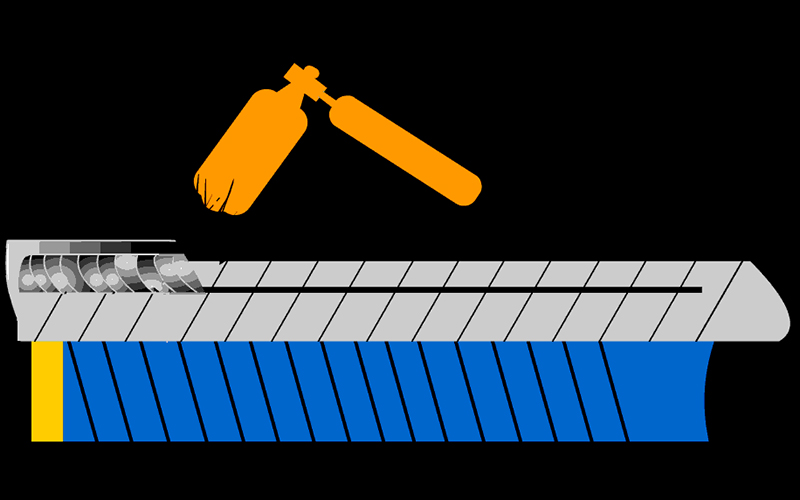

my country has conducted a pressure fatigue test on a three-layer heat-shrinkable simulated container. The test container has an inner diameter of 350mm, and each layer is welded from 6mm thick 15MnVR steel plates. Due to the small inner diameter of the container, the weld surface was not treated after welding. A section of the longitudinal weld on the inner surface was ground only because of the need to measure stress and paste resistance strain gauges. The container leaked after the pressure fatigue test. It was dissected and subjected to magnetic particle testing. It was found that the fusion line on one side of the longitudinal weld on the inner and outer surfaces of the inner layer cylinder had magnetic traces, indicating that the longitudinal weld of this layer had cracked, but the grinding area was intact, and there was no magnetic powder accumulation on the inner and outer surfaces.